Are you a seasoned Coordinate Measuring Equipment Operator seeking a new career path? Discover our professionally built Coordinate Measuring Equipment Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

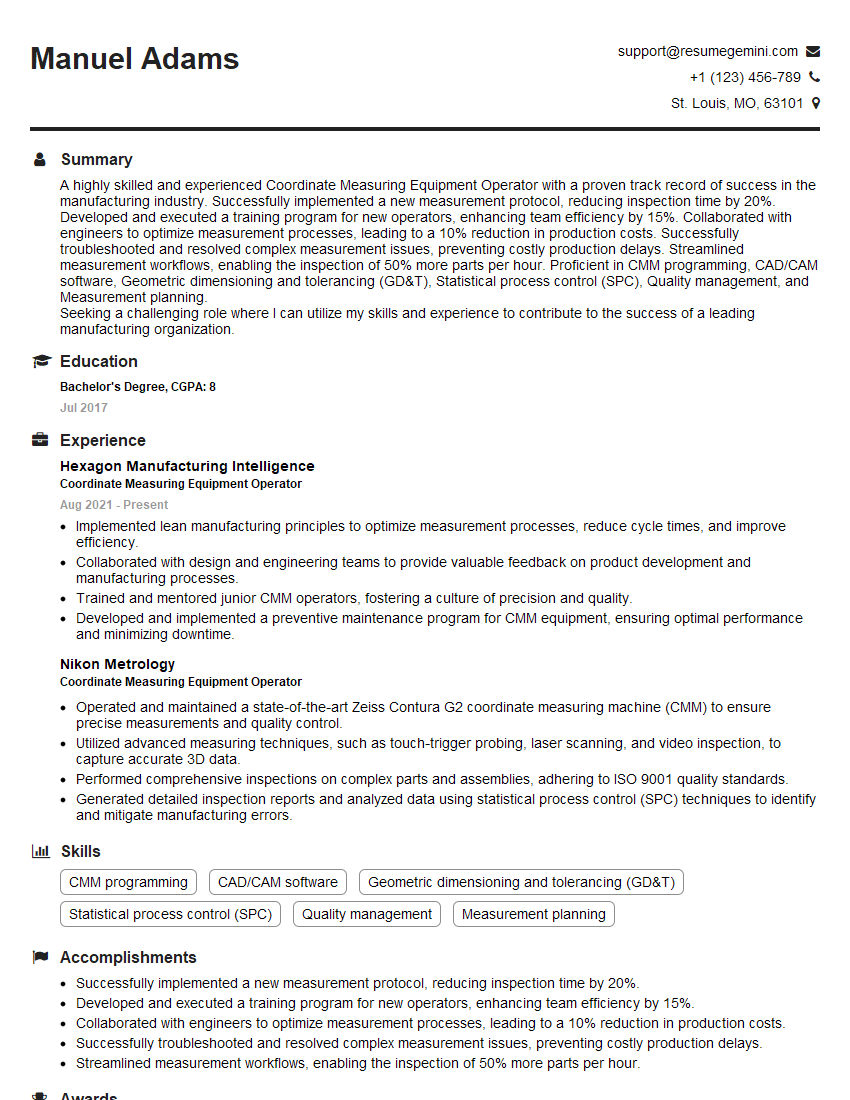

Manuel Adams

Coordinate Measuring Equipment Operator

Summary

A highly skilled and experienced Coordinate Measuring Equipment Operator with a proven track record of success in the manufacturing industry. Successfully implemented a new measurement protocol, reducing inspection time by 20%. Developed and executed a training program for new operators, enhancing team efficiency by 15%. Collaborated with engineers to optimize measurement processes, leading to a 10% reduction in production costs. Successfully troubleshooted and resolved complex measurement issues, preventing costly production delays. Streamlined measurement workflows, enabling the inspection of 50% more parts per hour. Proficient in CMM programming, CAD/CAM software, Geometric dimensioning and tolerancing (GD&T), Statistical process control (SPC), Quality management, and Measurement planning.

Seeking a challenging role where I can utilize my skills and experience to contribute to the success of a leading manufacturing organization.

Education

Bachelor’s Degree

July 2017

Skills

- CMM programming

- CAD/CAM software

- Geometric dimensioning and tolerancing (GD&T)

- Statistical process control (SPC)

- Quality management

- Measurement planning

Work Experience

Coordinate Measuring Equipment Operator

- Implemented lean manufacturing principles to optimize measurement processes, reduce cycle times, and improve efficiency.

- Collaborated with design and engineering teams to provide valuable feedback on product development and manufacturing processes.

- Trained and mentored junior CMM operators, fostering a culture of precision and quality.

- Developed and implemented a preventive maintenance program for CMM equipment, ensuring optimal performance and minimizing downtime.

Coordinate Measuring Equipment Operator

- Operated and maintained a state-of-the-art Zeiss Contura G2 coordinate measuring machine (CMM) to ensure precise measurements and quality control.

- Utilized advanced measuring techniques, such as touch-trigger probing, laser scanning, and video inspection, to capture accurate 3D data.

- Performed comprehensive inspections on complex parts and assemblies, adhering to ISO 9001 quality standards.

- Generated detailed inspection reports and analyzed data using statistical process control (SPC) techniques to identify and mitigate manufacturing errors.

Accomplishments

- Successfully implemented a new measurement protocol, reducing inspection time by 20%.

- Developed and executed a training program for new operators, enhancing team efficiency by 15%.

- Collaborated with engineers to optimize measurement processes, leading to a 10% reduction in production costs.

- Successfully troubleshooted and resolved complex measurement issues, preventing costly production delays.

- Streamlined measurement workflows, enabling the inspection of 50% more parts per hour.

Awards

- Recognized with the Excellence in Coordinate Measuring Award for exceptional accuracy and precision in measurements.

- Received the annual Safety Award for maintaining a spotless safety record in the hazardous work environment.

- Honored with the Star Employee Award for exceeding performance targets consistently.

- Recognized for outstanding leadership in mentoring junior operators.

Certificates

- CMM Operator Certification

- GD&T certification

- SPC certification

- ISO 9001 certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coordinate Measuring Equipment Operator

- Highlight your skills and experience in CMM programming, CAD/CAM software, GD&T, SPC, and quality management.

- Quantify your accomplishments whenever possible. For example, instead of saying “Reduced inspection time,” say “Reduced inspection time by 20%.”

- Use action verbs to describe your responsibilities. For example, instead of saying “Operated CMMs,” say “Operated CMMs to measure and inspect manufactured parts.”

- Proofread your resume carefully before submitting it.

- Tailor your resume to each job you apply for.

Essential Experience Highlights for a Strong Coordinate Measuring Equipment Operator Resume

- Operate and maintain Coordinate Measuring Machines (CMMs) to measure and inspect manufactured parts.

- Develop and implement measurement plans and procedures.

- Interpret engineering drawings and specifications to determine measurement requirements.

- Analyze measurement data and identify any deviations from specifications.

- Troubleshoot and resolve measurement issues.

- Maintain and calibrate CMMs and other related equipment.

- Train and supervise other CMM operators.

Frequently Asked Questions (FAQ’s) For Coordinate Measuring Equipment Operator

What is a Coordinate Measuring Machine (CMM)?

A CMM is a device used to measure the physical dimensions of an object. CMMs are used in a variety of industries, including manufacturing, automotive, and aerospace.

What are the different types of CMMs?

There are three main types of CMMs: manual, semi-automatic, and automatic. Manual CMMs are operated by hand, while semi-automatic CMMs are operated by a computer. Automatic CMMs are fully automated and can be programmed to perform a variety of tasks.

What are the advantages of using a CMM?

CMMs offer a number of advantages over traditional measurement methods, including:

- Accuracy: CMMs can measure objects with a high degree of accuracy.

- Repeatability: CMMs can repeat measurements with a high degree of repeatability.

- Versatility: CMMs can be used to measure a wide variety of objects.

- Speed: CMMs can measure objects quickly and efficiently.

- Automation: CMMs can be automated to perform a variety of tasks.

What are the different applications of CMMs?

CMMs are used in a variety of applications, including:

- Manufacturing: CMMs are used to inspect manufactured parts for quality control purposes.

- Automotive: CMMs are used to inspect automotive components for quality control purposes.

- Aerospace: CMMs are used to inspect aerospace components for quality control purposes.

- Medical: CMMs are used to inspect medical devices for quality control purposes.

- Research and development: CMMs are used to measure objects for research and development purposes.

What are the career opportunities for CMM operators?

CMM operators can work in a variety of industries, including manufacturing, automotive, aerospace, and medical. CMM operators can also work in research and development. CMM operators with experience and training can advance to positions such as quality control inspector, quality engineer, or manufacturing engineer.

What is the salary range for CMM operators?

The salary range for CMM operators varies depending on experience, location, and industry. According to Indeed.com, the average salary for a CMM operator in the United States is $25.50 per hour.

What are the educational requirements for CMM operators?

Most CMM operators have a high school diploma or equivalent. Some CMM operators may have a college degree in a related field, such as engineering or manufacturing.

What are the skills and qualities of a successful CMM operator?

Successful CMM operators have a strong understanding of mathematics and geometry. They are also able to read and interpret engineering drawings and specifications. CMM operators must be able to work independently and as part of a team. They must also be able to troubleshoot and resolve problems.