Are you a seasoned Coordinate Measuring Machine Operator (CMM Operator) seeking a new career path? Discover our professionally built Coordinate Measuring Machine Operator (CMM Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

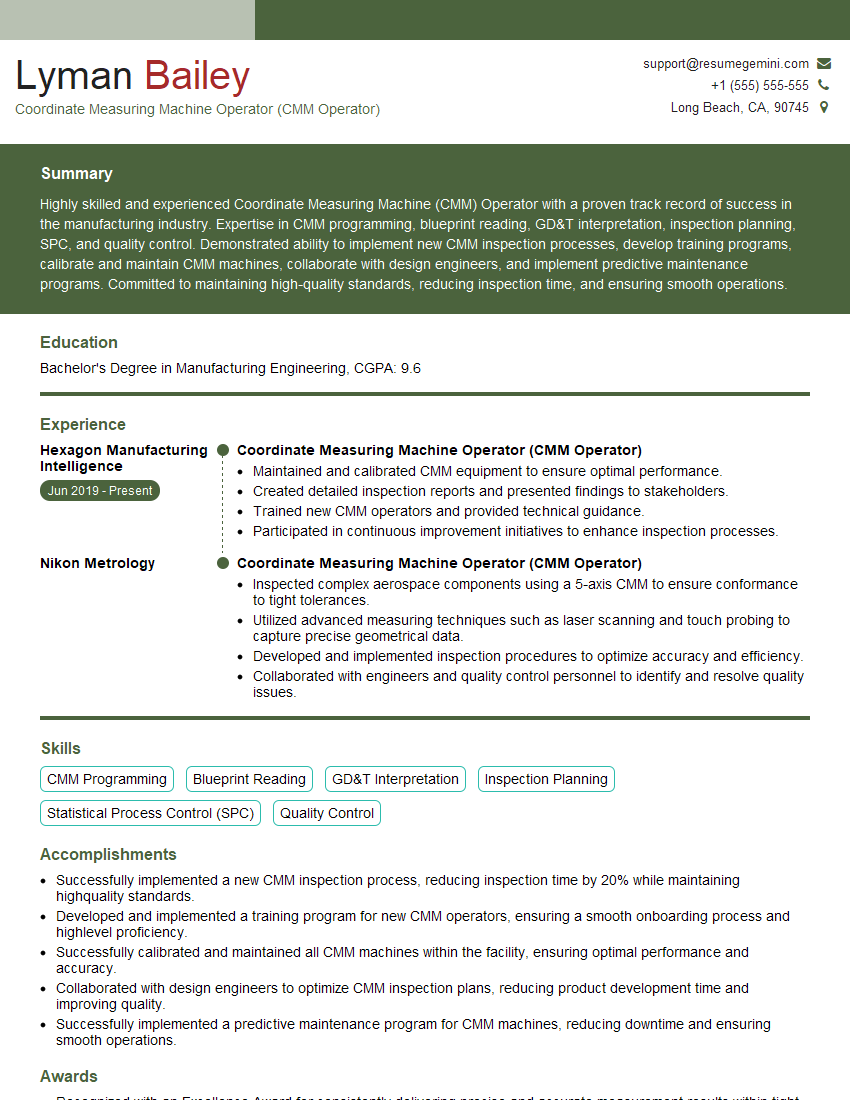

Lyman Bailey

Coordinate Measuring Machine Operator (CMM Operator)

Summary

Highly skilled and experienced Coordinate Measuring Machine (CMM) Operator with a proven track record of success in the manufacturing industry. Expertise in CMM programming, blueprint reading, GD&T interpretation, inspection planning, SPC, and quality control. Demonstrated ability to implement new CMM inspection processes, develop training programs, calibrate and maintain CMM machines, collaborate with design engineers, and implement predictive maintenance programs. Committed to maintaining high-quality standards, reducing inspection time, and ensuring smooth operations.

Education

Bachelor’s Degree in Manufacturing Engineering

May 2015

Skills

- CMM Programming

- Blueprint Reading

- GD&T Interpretation

- Inspection Planning

- Statistical Process Control (SPC)

- Quality Control

Work Experience

Coordinate Measuring Machine Operator (CMM Operator)

- Maintained and calibrated CMM equipment to ensure optimal performance.

- Created detailed inspection reports and presented findings to stakeholders.

- Trained new CMM operators and provided technical guidance.

- Participated in continuous improvement initiatives to enhance inspection processes.

Coordinate Measuring Machine Operator (CMM Operator)

- Inspected complex aerospace components using a 5-axis CMM to ensure conformance to tight tolerances.

- Utilized advanced measuring techniques such as laser scanning and touch probing to capture precise geometrical data.

- Developed and implemented inspection procedures to optimize accuracy and efficiency.

- Collaborated with engineers and quality control personnel to identify and resolve quality issues.

Accomplishments

- Successfully implemented a new CMM inspection process, reducing inspection time by 20% while maintaining highquality standards.

- Developed and implemented a training program for new CMM operators, ensuring a smooth onboarding process and highlevel proficiency.

- Successfully calibrated and maintained all CMM machines within the facility, ensuring optimal performance and accuracy.

- Collaborated with design engineers to optimize CMM inspection plans, reducing product development time and improving quality.

- Successfully implemented a predictive maintenance program for CMM machines, reducing downtime and ensuring smooth operations.

Awards

- Recognized with an Excellence Award for consistently delivering precise and accurate measurement results within tight tolerances.

- Received the CMM Operator of the Year award for exceptional performance, dedication, and expertise.

- Awarded a Quality Improvement Award for identifying and resolving a critical measurement issue, preventing potential quality defects.

- Recognized with a Safety Award for consistently adhering to safety protocols and promoting a safe work environment.

Certificates

- CMM Operator Certification (CMMOC)

- ASQ Certified Quality Inspector (CQI)

- Coordinate Measuring Machine Society (CMMS) Certification

- American Society for Quality (ASQ) Membership

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coordinate Measuring Machine Operator (CMM Operator)

- Highlight your skills and experience in CMM programming, blueprint reading, GD&T interpretation, inspection planning, SPC, and quality control.

- Showcase your ability to implement new CMM inspection processes, develop training programs, calibrate and maintain CMM machines, and collaborate with design engineers.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Proofread your resume carefully for any errors before submitting it to potential employers.

Essential Experience Highlights for a Strong Coordinate Measuring Machine Operator (CMM Operator) Resume

- Program and operate CMM machines to inspect and measure manufactured parts.

- Interpret blueprints and GD&T specifications to determine inspection requirements.

- Develop and implement inspection plans to ensure that parts meet quality standards.

- Calibrate and maintain CMM machines to ensure accuracy and reliability.

- Troubleshoot and resolve any issues that arise during the inspection process.

- Analyze inspection data and identify trends to improve quality control processes.

- Collaborate with design engineers to optimize CMM inspection plans and reduce product development time.

Frequently Asked Questions (FAQ’s) For Coordinate Measuring Machine Operator (CMM Operator)

What is a CMM Operator?

A CMM Operator is responsible for operating and programming coordinate measuring machines (CMMs) to inspect and measure manufactured parts. They interpret blueprints and GD&T specifications, develop and implement inspection plans, calibrate and maintain CMM machines, and analyze inspection data to identify trends and improve quality control processes.

What skills are required to be a successful CMM Operator?

Successful CMM Operators typically have a strong understanding of CMM programming, blueprint reading, GD&T interpretation, inspection planning, SPC, and quality control. They are also proficient in operating and maintaining CMM machines, and have a keen eye for detail and a commitment to quality.

What are the career prospects for CMM Operators?

CMM Operators are in high demand in the manufacturing industry. As the use of CMMs becomes more widespread, the demand for skilled CMM Operators is expected to grow. CMM Operators can advance their careers by developing specialized skills, such as programming complex CMM inspections or working with specific types of CMMs.

What is the average salary for a CMM Operator?

The average salary for a CMM Operator varies depending on experience, skills, and location. According to Indeed, the average salary for a CMM Operator in the United States is $25.62 per hour.

What are the benefits of working as a CMM Operator?

CMM Operators enjoy a number of benefits, including job security, a competitive salary, and the opportunity to work with cutting-edge technology. CMM Operators also have the opportunity to make a real difference in the quality of manufactured products.