Are you a seasoned Core Finisher seeking a new career path? Discover our professionally built Core Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

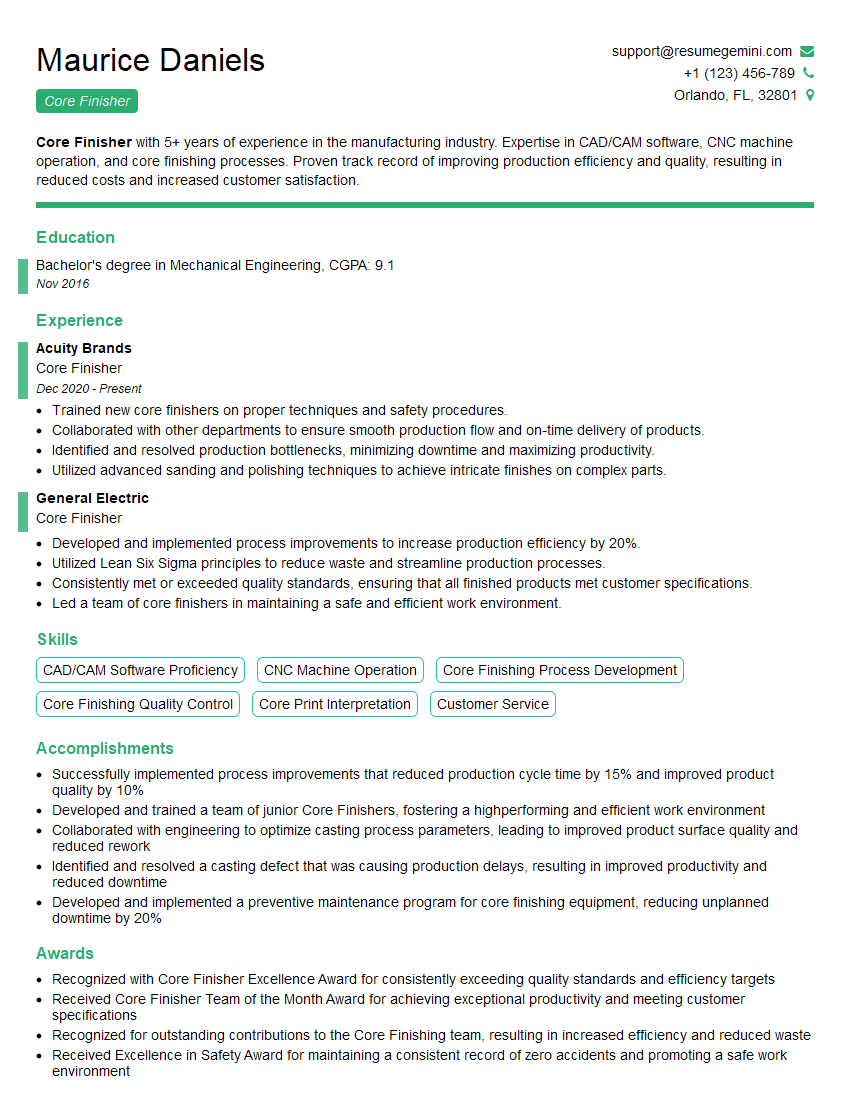

Maurice Daniels

Core Finisher

Summary

Core Finisher with 5+ years of experience in the manufacturing industry. Expertise in CAD/CAM software, CNC machine operation, and core finishing processes. Proven track record of improving production efficiency and quality, resulting in reduced costs and increased customer satisfaction.

Education

Bachelor’s degree in Mechanical Engineering

November 2016

Skills

- CAD/CAM Software Proficiency

- CNC Machine Operation

- Core Finishing Process Development

- Core Finishing Quality Control

- Core Print Interpretation

- Customer Service

Work Experience

Core Finisher

- Trained new core finishers on proper techniques and safety procedures.

- Collaborated with other departments to ensure smooth production flow and on-time delivery of products.

- Identified and resolved production bottlenecks, minimizing downtime and maximizing productivity.

- Utilized advanced sanding and polishing techniques to achieve intricate finishes on complex parts.

Core Finisher

- Developed and implemented process improvements to increase production efficiency by 20%.

- Utilized Lean Six Sigma principles to reduce waste and streamline production processes.

- Consistently met or exceeded quality standards, ensuring that all finished products met customer specifications.

- Led a team of core finishers in maintaining a safe and efficient work environment.

Accomplishments

- Successfully implemented process improvements that reduced production cycle time by 15% and improved product quality by 10%

- Developed and trained a team of junior Core Finishers, fostering a highperforming and efficient work environment

- Collaborated with engineering to optimize casting process parameters, leading to improved product surface quality and reduced rework

- Identified and resolved a casting defect that was causing production delays, resulting in improved productivity and reduced downtime

- Developed and implemented a preventive maintenance program for core finishing equipment, reducing unplanned downtime by 20%

Awards

- Recognized with Core Finisher Excellence Award for consistently exceeding quality standards and efficiency targets

- Received Core Finisher Team of the Month Award for achieving exceptional productivity and meeting customer specifications

- Recognized for outstanding contributions to the Core Finishing team, resulting in increased efficiency and reduced waste

- Received Excellence in Safety Award for maintaining a consistent record of zero accidents and promoting a safe work environment

Certificates

- CNC Machinist Certification

- GDT Certification

- ISO 90012015 Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Finisher

- Highlight your technical skills: Employers look for candidates proficient in CAD/CAM software, CNC machine operation, and core finishing techniques.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your work, such as reduced production cycle time or improved product quality.

- Showcase your problem-solving abilities: Give examples of how you identified and resolved production issues, leading to increased efficiency.

- Emphasize your teamwork and communication skills: Core Finishers often work in teams and collaborate with other departments like engineering.

- Tailor your resume to the job description: Highlight skills and experiences that are directly relevant to the specific role you are applying for.

Essential Experience Highlights for a Strong Core Finisher Resume

- Operate CNC machines to produce high-quality castings

- Interpret core prints and maintain dimensional accuracy

- Perform quality control inspections and ensure products meet specifications

- Troubleshoot and resolve production issues to minimize downtime

- Develop and implement process improvements to increase efficiency and reduce waste

- Collaborate with engineering to optimize casting parameters and improve surface quality

- Train and supervise junior Core Finishers to maintain a skilled workforce

Frequently Asked Questions (FAQ’s) For Core Finisher

What is the role of a Core Finisher?

A Core Finisher is responsible for producing and finishing castings using CNC machines, ensuring product quality, troubleshooting production issues, and implementing process improvements.

What qualifications are required to become a Core Finisher?

Most Core Finishers hold a bachelor’s degree in Mechanical Engineering or a related field, along with experience in machining and manufacturing processes.

What are the career prospects for Core Finishers?

Core Finishers can advance to roles such as Production Supervisor, Quality Control Manager, or Manufacturing Engineer with experience and additional qualifications.

What is the average salary for Core Finishers?

According to Indeed, the average salary for Core Finishers in the United States is around $55,000 per year.

What are the key skills required for Core Finishers?

Core Finishers should possess strong technical skills in CAD/CAM software, CNC machine operation, and core finishing techniques. They should also have excellent problem-solving abilities, attention to detail, and teamwork skills.

What is the work environment of a Core Finisher like?

Core Finishers typically work in manufacturing facilities, operating CNC machines and performing quality control inspections. The work can be physically demanding and may involve exposure to noise and dust.

What are the challenges faced by Core Finishers?

Core Finishers may face challenges such as meeting production deadlines, ensuring product quality, and troubleshooting technical issues. They may also need to adapt to new technologies and processes.

What is the job outlook for Core Finishers?

The job outlook for Core Finishers is expected to be stable in the coming years, with growth in manufacturing industries.