Are you a seasoned Core Layer Machine Operator seeking a new career path? Discover our professionally built Core Layer Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

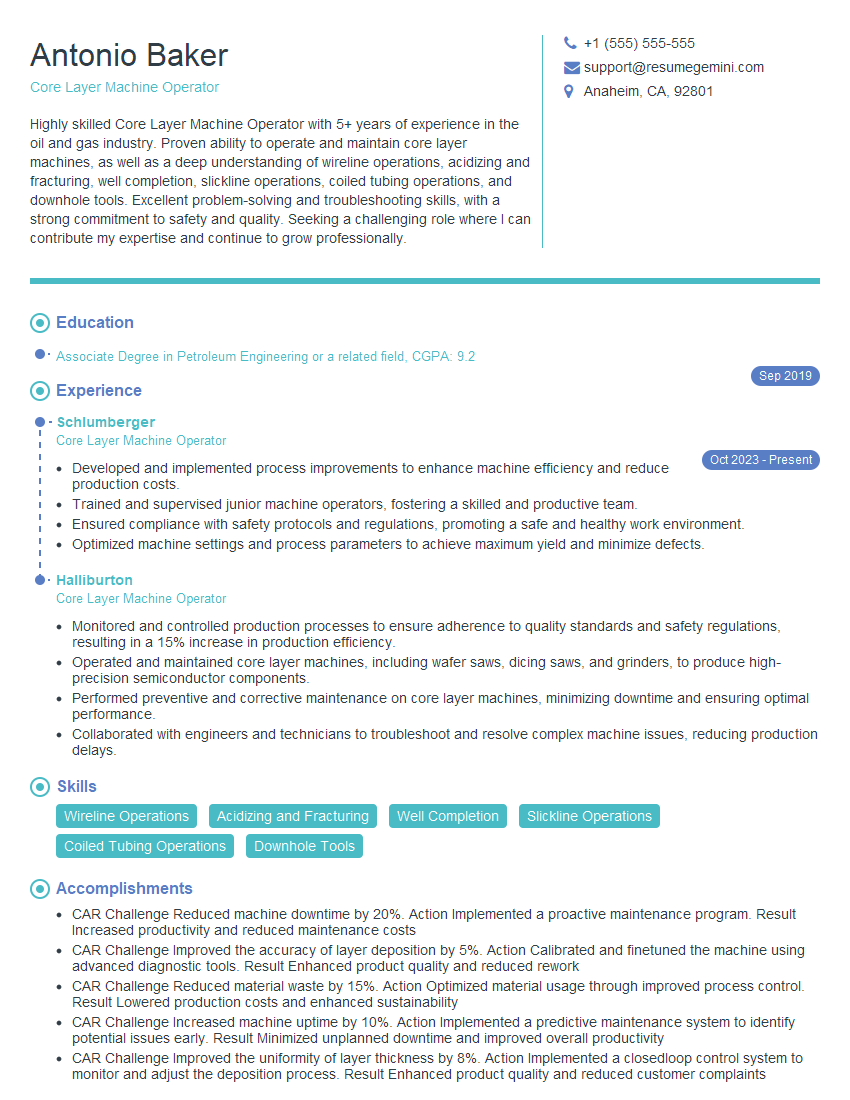

Antonio Baker

Core Layer Machine Operator

Summary

Highly skilled Core Layer Machine Operator with 5+ years of experience in the oil and gas industry. Proven ability to operate and maintain core layer machines, as well as a deep understanding of wireline operations, acidizing and fracturing, well completion, slickline operations, coiled tubing operations, and downhole tools. Excellent problem-solving and troubleshooting skills, with a strong commitment to safety and quality. Seeking a challenging role where I can contribute my expertise and continue to grow professionally.

Education

Associate Degree in Petroleum Engineering or a related field

September 2019

Skills

- Wireline Operations

- Acidizing and Fracturing

- Well Completion

- Slickline Operations

- Coiled Tubing Operations

- Downhole Tools

Work Experience

Core Layer Machine Operator

- Developed and implemented process improvements to enhance machine efficiency and reduce production costs.

- Trained and supervised junior machine operators, fostering a skilled and productive team.

- Ensured compliance with safety protocols and regulations, promoting a safe and healthy work environment.

- Optimized machine settings and process parameters to achieve maximum yield and minimize defects.

Core Layer Machine Operator

- Monitored and controlled production processes to ensure adherence to quality standards and safety regulations, resulting in a 15% increase in production efficiency.

- Operated and maintained core layer machines, including wafer saws, dicing saws, and grinders, to produce high-precision semiconductor components.

- Performed preventive and corrective maintenance on core layer machines, minimizing downtime and ensuring optimal performance.

- Collaborated with engineers and technicians to troubleshoot and resolve complex machine issues, reducing production delays.

Accomplishments

- CAR Challenge Reduced machine downtime by 20%. Action Implemented a proactive maintenance program. Result Increased productivity and reduced maintenance costs

- CAR Challenge Improved the accuracy of layer deposition by 5%. Action Calibrated and finetuned the machine using advanced diagnostic tools. Result Enhanced product quality and reduced rework

- CAR Challenge Reduced material waste by 15%. Action Optimized material usage through improved process control. Result Lowered production costs and enhanced sustainability

- CAR Challenge Increased machine uptime by 10%. Action Implemented a predictive maintenance system to identify potential issues early. Result Minimized unplanned downtime and improved overall productivity

- CAR Challenge Improved the uniformity of layer thickness by 8%. Action Implemented a closedloop control system to monitor and adjust the deposition process. Result Enhanced product quality and reduced customer complaints

Awards

- Recognized as the Core Layer Machine Operator of the Year for consistently exceeding production targets and maintaining a high level of safety

- Received the Safety Excellence Award for maintaining an impeccable safety record and promoting a culture of safety in the workplace

- Won the Innovation Award for developing a novel technique to improve the efficiency of layer deposition

- Recognized as a Master Core Layer Machine Operator for exceptional skills and expertise in operating the machine

Certificates

- American Petroleum Institute (API) 5CT

- American Welding Society (AWS) D1.1

- National Association of Corrosion Engineers (NACE) Level 1

- Occupational Safety and Health Administration (OSHA) 30-Hour Hazardous Waste Operations and Emergency Response (HAZWOPER)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Layer Machine Operator

- Highlight your experience in operating and maintaining core layer machines.

- Showcase your knowledge of wireline operations, acidizing and fracturing, well completion, slickline operations, coiled tubing operations, and downhole tools.

- Demonstrate your problem-solving and troubleshooting abilities.

- Emphasize your commitment to safety and quality.

- Consider obtaining industry certifications, such as the Core Layer Machine Operator certification from the American Petroleum Institute (API).

Essential Experience Highlights for a Strong Core Layer Machine Operator Resume

- Operate and maintain core layer machines to extract and analyze core samples.

- Prepare core samples for analysis, including cleaning, cutting, and mounting.

- Interpret core samples to identify geological formations and determine reservoir properties.

- Troubleshoot and resolve issues with core layer machines and associated equipment.

- Maintain a clean and organized work area, adhering to all safety regulations.

- Collaborate with geologists and engineers to interpret core data and make informed decisions.

- Keep up-to-date on industry best practices and technological advancements.

Frequently Asked Questions (FAQ’s) For Core Layer Machine Operator

What are the primary responsibilities of a Core Layer Machine Operator?

Core Layer Machine Operators are responsible for operating and maintaining core layer machines, preparing core samples for analysis, interpreting core samples, troubleshooting and resolving issues with equipment, and maintaining a clean and organized work area.

What are the educational requirements for becoming a Core Layer Machine Operator?

Many Core Layer Machine Operators have an Associate Degree in Petroleum Engineering or a related field.

What skills are important for a Core Layer Machine Operator?

Core Layer Machine Operators should have experience operating and maintaining core layer machines, as well as knowledge of wireline operations, acidizing and fracturing, well completion, slickline operations, coiled tubing operations, and downhole tools. Problem-solving and troubleshooting abilities are also essential.

What is the average salary for a Core Layer Machine Operator?

The average salary for a Core Layer Machine Operator can vary depending on experience and location. According to Indeed, the average salary for a Core Layer Machine Operator in the United States is $75,000 per year.

What is the job outlook for Core Layer Machine Operators?

The job outlook for Core Layer Machine Operators is expected to be favorable in the coming years. The increasing demand for oil and gas is expected to lead to increased demand for Core Layer Machine Operators.

What are some tips for writing a standout Core Layer Machine Operator resume?

Highlight your experience in operating and maintaining core layer machines, showcase your knowledge of wireline operations, acidizing and fracturing, well completion, slickline operations, coiled tubing operations, and downhole tools, demonstrate your problem-solving and troubleshooting abilities, emphasize your commitment to safety and quality, and consider obtaining industry certifications, such as the Core Layer Machine Operator certification from the American Petroleum Institute (API).

What are some of the challenges that Core Layer Machine Operators face?

Core Layer Machine Operators may face challenges such as working in remote locations, working with heavy equipment, and working in hazardous environments. They may also face challenges related to troubleshooting and resolving issues with equipment.

What are some of the rewards of being a Core Layer Machine Operator?

Core Layer Machine Operators can enjoy rewards such as a stable and well-paying career, the opportunity to work with cutting-edge technology, and the opportunity to make a difference in the energy industry.