Are you a seasoned Core Winder Machine Operator seeking a new career path? Discover our professionally built Core Winder Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

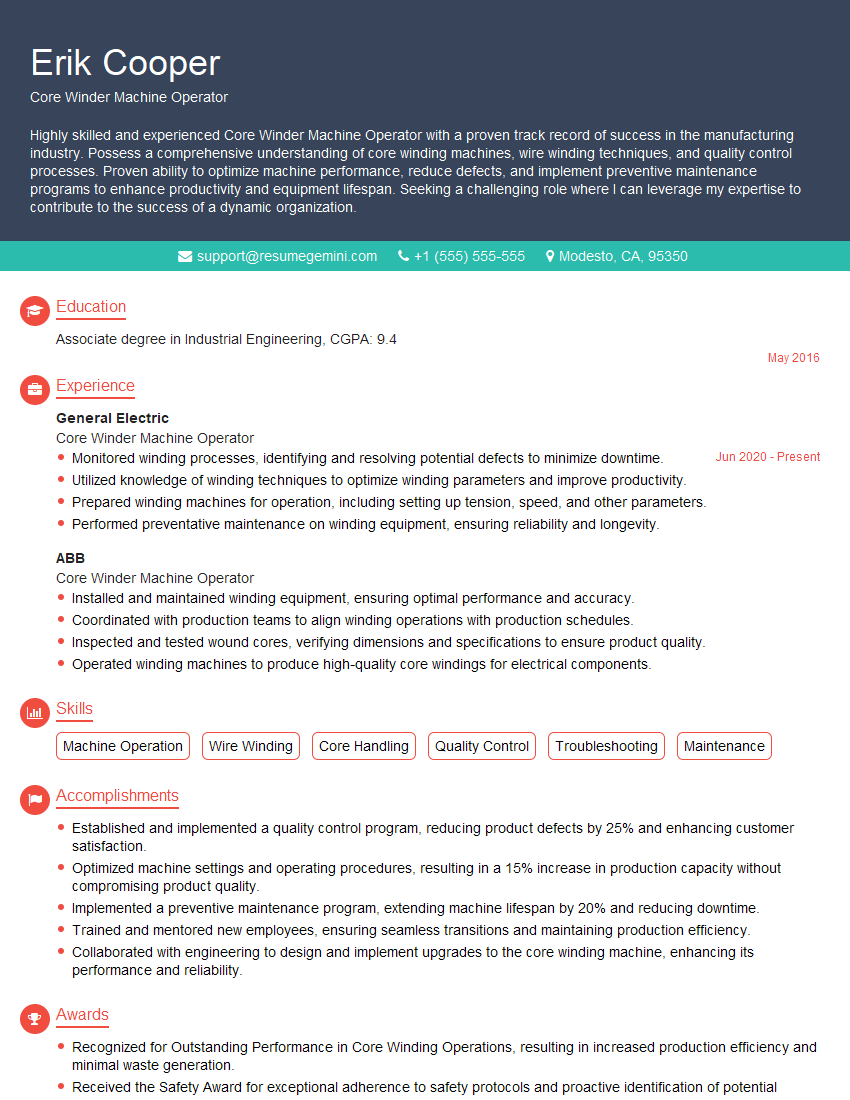

Erik Cooper

Core Winder Machine Operator

Summary

Highly skilled and experienced Core Winder Machine Operator with a proven track record of success in the manufacturing industry. Possess a comprehensive understanding of core winding machines, wire winding techniques, and quality control processes. Proven ability to optimize machine performance, reduce defects, and implement preventive maintenance programs to enhance productivity and equipment lifespan. Seeking a challenging role where I can leverage my expertise to contribute to the success of a dynamic organization.

Education

Associate degree in Industrial Engineering

May 2016

Skills

- Machine Operation

- Wire Winding

- Core Handling

- Quality Control

- Troubleshooting

- Maintenance

Work Experience

Core Winder Machine Operator

- Monitored winding processes, identifying and resolving potential defects to minimize downtime.

- Utilized knowledge of winding techniques to optimize winding parameters and improve productivity.

- Prepared winding machines for operation, including setting up tension, speed, and other parameters.

- Performed preventative maintenance on winding equipment, ensuring reliability and longevity.

Core Winder Machine Operator

- Installed and maintained winding equipment, ensuring optimal performance and accuracy.

- Coordinated with production teams to align winding operations with production schedules.

- Inspected and tested wound cores, verifying dimensions and specifications to ensure product quality.

- Operated winding machines to produce high-quality core windings for electrical components.

Accomplishments

- Established and implemented a quality control program, reducing product defects by 25% and enhancing customer satisfaction.

- Optimized machine settings and operating procedures, resulting in a 15% increase in production capacity without compromising product quality.

- Implemented a preventive maintenance program, extending machine lifespan by 20% and reducing downtime.

- Trained and mentored new employees, ensuring seamless transitions and maintaining production efficiency.

- Collaborated with engineering to design and implement upgrades to the core winding machine, enhancing its performance and reliability.

Awards

- Recognized for Outstanding Performance in Core Winding Operations, resulting in increased production efficiency and minimal waste generation.

- Received the Safety Award for exceptional adherence to safety protocols and proactive identification of potential hazards.

- Honored with the Employee Recognition Award for consistently exceeding production targets and maintaining highquality standards.

- Nominated for the Core Winder Machine Operator of the Year award for exemplary contributions to the team and the company.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Six Sigma Black Belt (CSSBB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Winder Machine Operator

- Highlight your experience and skills in core winding machine operation and maintenance.

- Quantify your accomplishments using specific metrics to demonstrate your impact.

- Showcase your understanding of quality control processes and how you have used them to improve production.

- Emphasize your ability to work independently and as part of a team.

- Tailor your resume to the specific job you are applying for.

Essential Experience Highlights for a Strong Core Winder Machine Operator Resume

- Operate and monitor core winding machines to produce high-quality electrical components.

- Inspect and evaluate incoming materials to ensure they meet specifications.

- Calibrate and adjust machines to optimize performance and minimize defects.

- Conduct routine maintenance and repairs to keep machines running smoothly.

- Troubleshoot and resolve production issues to minimize downtime.

- Monitor production data and identify areas for improvement.

- Maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Core Winder Machine Operator

What is a Core Winder Machine Operator?

A Core Winder Machine Operator is responsible for operating and maintaining core winding machines used in the manufacturing of electrical components. They ensure that the machines are operating correctly, the materials meet specifications, and the final products are of high quality.

What are the key skills and qualifications for a Core Winder Machine Operator?

Key skills and qualifications include experience in operating core winding machines, knowledge of wire winding techniques, quality control processes, and maintenance procedures. Additionally, a high school diploma or equivalent is typically required.

What is the work environment of a Core Winder Machine Operator?

Core Winder Machine Operators typically work in manufacturing facilities, operating machines in a production environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.

What is the career outlook for a Core Winder Machine Operator?

The career outlook for Core Winder Machine Operators is expected to be good, with a projected 4% growth in employment from 2021 to 2031. This growth is driven by the increasing demand for electrical components in various industries, such as automotive, electronics, and construction.

What are the earning prospects for a Core Winder Machine Operator?

Earning prospects for Core Winder Machine Operators vary depending on factors such as experience, location, and industry. According to Indeed, the average salary for a Core Winder Machine Operator in the United States is around $20 per hour.

What are the benefits of a career as a Core Winder Machine Operator?

Benefits of a career as a Core Winder Machine Operator include job security, opportunities for advancement, and competitive salaries. Additionally, Core Winder Machine Operators play a vital role in the manufacturing process, helping to produce high-quality electrical components that are used in a wide range of products.

What are the challenges of a career as a Core Winder Machine Operator?

Challenges of a career as a Core Winder Machine Operator include working in a production environment, which can be noisy and repetitive. Additionally, Core Winder Machine Operators may be required to work overtime or on weekends to meet production demands.

What advice would you give to someone considering a career as a Core Winder Machine Operator?

If you are considering a career as a Core Winder Machine Operator, I would advise you to gain experience in operating core winding machines and learning about wire winding techniques. Additionally, it is important to be able to work independently and as part of a team, and to be able to follow instructions and work under pressure.