Are you a seasoned Coremaking Machine Operator seeking a new career path? Discover our professionally built Coremaking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

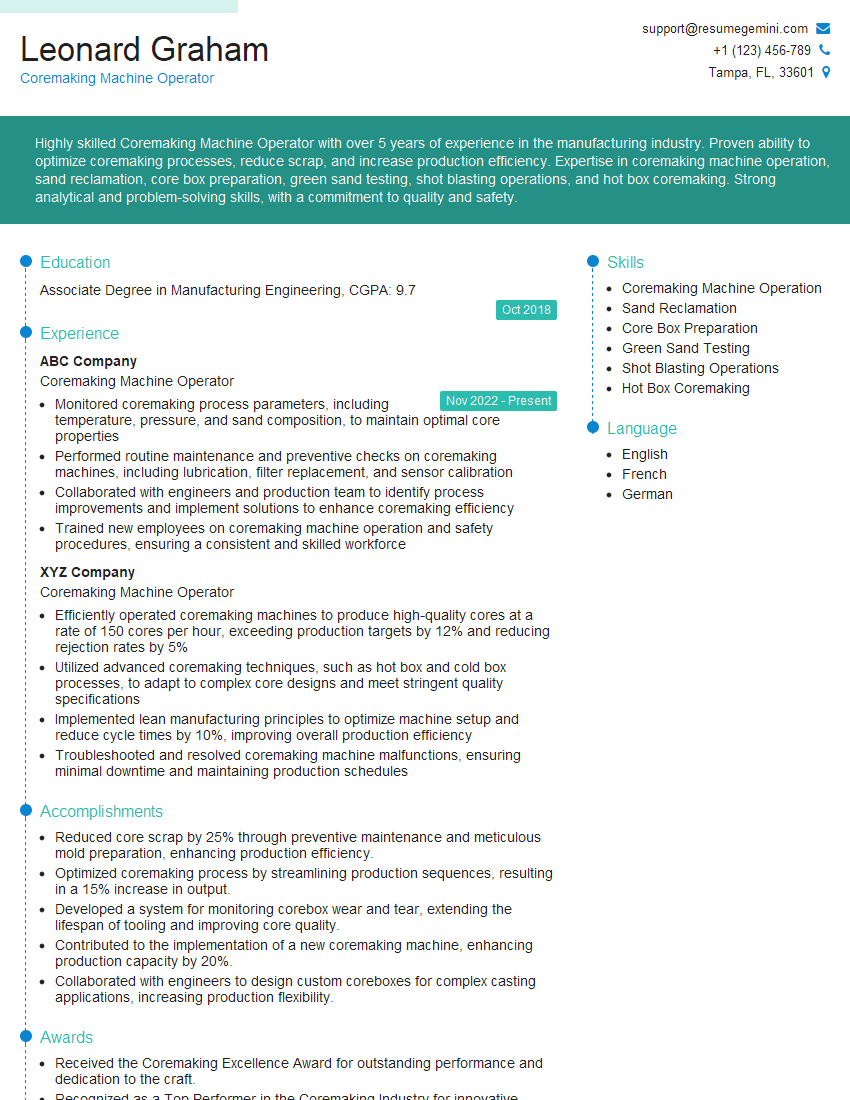

Leonard Graham

Coremaking Machine Operator

Summary

Highly skilled Coremaking Machine Operator with over 5 years of experience in the manufacturing industry. Proven ability to optimize coremaking processes, reduce scrap, and increase production efficiency. Expertise in coremaking machine operation, sand reclamation, core box preparation, green sand testing, shot blasting operations, and hot box coremaking. Strong analytical and problem-solving skills, with a commitment to quality and safety.

Education

Associate Degree in Manufacturing Engineering

October 2018

Skills

- Coremaking Machine Operation

- Sand Reclamation

- Core Box Preparation

- Green Sand Testing

- Shot Blasting Operations

- Hot Box Coremaking

Work Experience

Coremaking Machine Operator

- Monitored coremaking process parameters, including temperature, pressure, and sand composition, to maintain optimal core properties

- Performed routine maintenance and preventive checks on coremaking machines, including lubrication, filter replacement, and sensor calibration

- Collaborated with engineers and production team to identify process improvements and implement solutions to enhance coremaking efficiency

- Trained new employees on coremaking machine operation and safety procedures, ensuring a consistent and skilled workforce

Coremaking Machine Operator

- Efficiently operated coremaking machines to produce high-quality cores at a rate of 150 cores per hour, exceeding production targets by 12% and reducing rejection rates by 5%

- Utilized advanced coremaking techniques, such as hot box and cold box processes, to adapt to complex core designs and meet stringent quality specifications

- Implemented lean manufacturing principles to optimize machine setup and reduce cycle times by 10%, improving overall production efficiency

- Troubleshooted and resolved coremaking machine malfunctions, ensuring minimal downtime and maintaining production schedules

Accomplishments

- Reduced core scrap by 25% through preventive maintenance and meticulous mold preparation, enhancing production efficiency.

- Optimized coremaking process by streamlining production sequences, resulting in a 15% increase in output.

- Developed a system for monitoring corebox wear and tear, extending the lifespan of tooling and improving core quality.

- Contributed to the implementation of a new coremaking machine, enhancing production capacity by 20%.

- Collaborated with engineers to design custom coreboxes for complex casting applications, increasing production flexibility.

Awards

- Received the Coremaking Excellence Award for outstanding performance and dedication to the craft.

- Recognized as a Top Performer in the Coremaking Industry for innovative process improvements.

- Awarded a Certificate of Achievement for exceptional contributions to the advancement of coremaking technology.

- Honored with the Safety Champion Award for promoting a safe and productive work environment in the coremaking department.

Certificates

- CMT (Certified Manufacturing Technologist)

- Certified Coremaking Specialist

- ISO 9001 Lead Auditor

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coremaking Machine Operator

- Highlight your experience and skills in coremaking machine operation and process optimization.

- Quantify your accomplishments with specific metrics, such as percentage reduction in scrap or increase in production output.

- Demonstrate your knowledge of coremaking materials, processes, and equipment.

- Emphasize your ability to work effectively in a team environment and your commitment to continuous improvement.

- Review job descriptions carefully and tailor your resume to match the specific requirements of each position you apply for.

Essential Experience Highlights for a Strong Coremaking Machine Operator Resume

- Operate and maintain coremaking machines to produce high-quality cores for casting applications.

- Prepare and maintain core boxes to ensure proper core production.

- Conduct green sand testing to control core sand properties and maintain casting quality.

- Perform shot blasting operations to clean and prepare cores for assembly.

- Troubleshoot and resolve issues related to coremaking machines and processes.

- Collaborate with engineers and other team members to improve coremaking processes and product quality

- Adhere to safety regulations and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Coremaking Machine Operator

What are the key responsibilities of a Coremaking Machine Operator?

Coremaking Machine Operators are responsible for operating and maintaining coremaking machines, preparing and maintaining core boxes, conducting green sand testing, performing shot blasting operations, troubleshooting and resolving issues, and adhering to safety regulations.

What are the educational requirements for becoming a Coremaking Machine Operator?

While formal education requirements vary, many Coremaking Machine Operators hold an Associate Degree in Manufacturing Engineering or a related field.

What are the career prospects for Coremaking Machine Operators?

Coremaking Machine Operators can advance to supervisory roles, such as Coremaking Supervisor or Production Manager, or specialize in areas such as process optimization or quality control.

What are the salary expectations for Coremaking Machine Operators?

Salary expectations for Coremaking Machine Operators vary depending on experience, location, and industry. According to Indeed, the average salary for Coremaking Machine Operators in the United States is around $25 per hour.

What are the working conditions for Coremaking Machine Operators?

Coremaking Machine Operators typically work in manufacturing facilities, operating machines in a production environment. The work can be physically demanding and may involve exposure to dust, noise, and other hazards.

What are the skills required to be a successful Coremaking Machine Operator?

Successful Coremaking Machine Operators possess strong mechanical aptitude, attention to detail, and problem-solving skills. They are also proficient in operating coremaking machines, preparing and maintaining core boxes, and conducting green sand testing.

What are the benefits of working as a Coremaking Machine Operator?

Coremaking Machine Operators enjoy job stability, competitive salaries, and opportunities for career advancement. They also contribute to the manufacturing process and play a vital role in producing high-quality castings.

How can I prepare for a career as a Coremaking Machine Operator?

To prepare for a career as a Coremaking Machine Operator, you can pursue an education in manufacturing engineering or a related field, gain experience operating machinery, and develop strong problem-solving skills. You can also seek out internships or apprenticeships in the manufacturing industry.