Are you a seasoned Coreroom Foundry Laborer seeking a new career path? Discover our professionally built Coreroom Foundry Laborer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

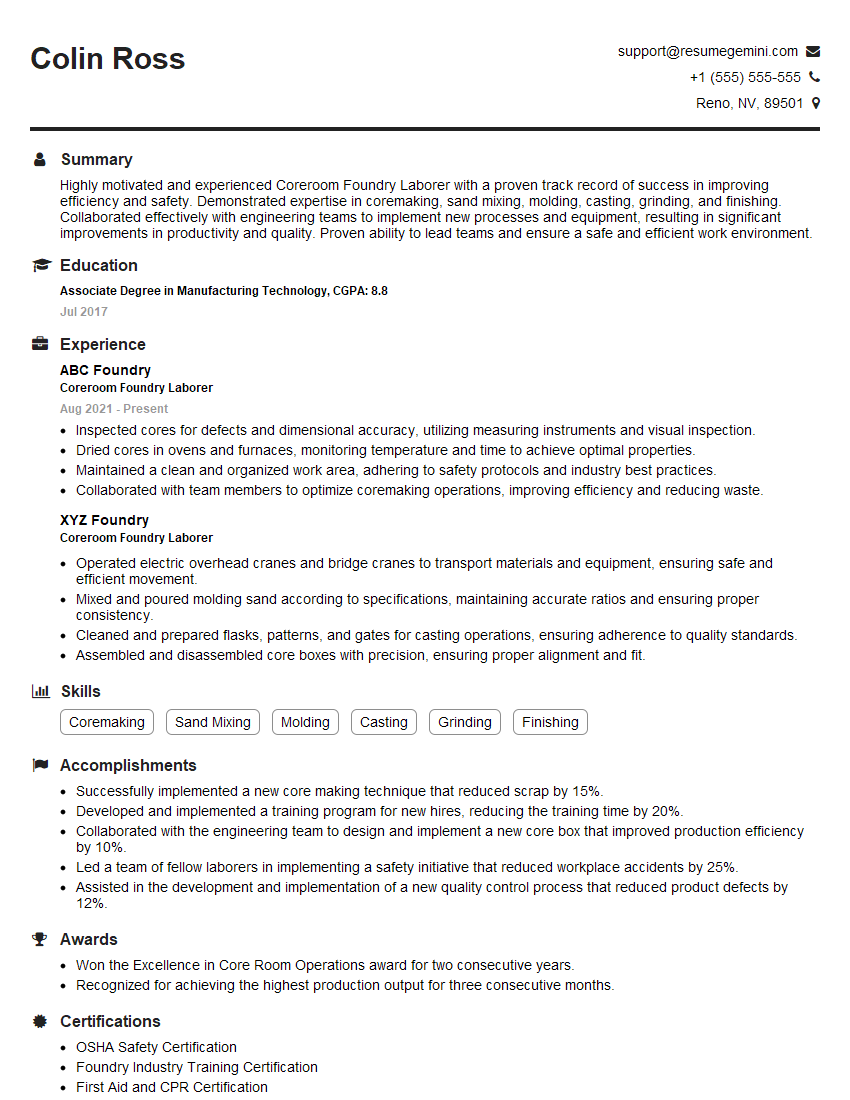

Colin Ross

Coreroom Foundry Laborer

Summary

Highly motivated and experienced Coreroom Foundry Laborer with a proven track record of success in improving efficiency and safety. Demonstrated expertise in coremaking, sand mixing, molding, casting, grinding, and finishing. Collaborated effectively with engineering teams to implement new processes and equipment, resulting in significant improvements in productivity and quality. Proven ability to lead teams and ensure a safe and efficient work environment.

Education

Associate Degree in Manufacturing Technology

July 2017

Skills

- Coremaking

- Sand Mixing

- Molding

- Casting

- Grinding

- Finishing

Work Experience

Coreroom Foundry Laborer

- Inspected cores for defects and dimensional accuracy, utilizing measuring instruments and visual inspection.

- Dried cores in ovens and furnaces, monitoring temperature and time to achieve optimal properties.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Collaborated with team members to optimize coremaking operations, improving efficiency and reducing waste.

Coreroom Foundry Laborer

- Operated electric overhead cranes and bridge cranes to transport materials and equipment, ensuring safe and efficient movement.

- Mixed and poured molding sand according to specifications, maintaining accurate ratios and ensuring proper consistency.

- Cleaned and prepared flasks, patterns, and gates for casting operations, ensuring adherence to quality standards.

- Assembled and disassembled core boxes with precision, ensuring proper alignment and fit.

Accomplishments

- Successfully implemented a new core making technique that reduced scrap by 15%.

- Developed and implemented a training program for new hires, reducing the training time by 20%.

- Collaborated with the engineering team to design and implement a new core box that improved production efficiency by 10%.

- Led a team of fellow laborers in implementing a safety initiative that reduced workplace accidents by 25%.

- Assisted in the development and implementation of a new quality control process that reduced product defects by 12%.

Awards

- Won the Excellence in Core Room Operations award for two consecutive years.

- Recognized for achieving the highest production output for three consecutive months.

Certificates

- OSHA Safety Certification

- Foundry Industry Training Certification

- First Aid and CPR Certification

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coreroom Foundry Laborer

- Highlight your technical skills and experience in coremaking, sand mixing, molding, casting, grinding, and finishing.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your ability to work independently and as part of a team, and emphasize your commitment to safety.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Coreroom Foundry Laborer Resume

- Prepare and mix sand according to specifications to create molds and cores for castings

- Operate core-making machines to produce cores for molds

- Inspect cores and molds for defects and ensure they meet quality standards

- Assemble and disassemble molds and cores using hand tools and lifting equipment

- Operate molding machines to pour molten metal into molds

- Remove castings from molds once they have cooled and solidified

- Grind and finish castings to remove imperfections and prepare them for further processing

Frequently Asked Questions (FAQ’s) For Coreroom Foundry Laborer

What are the typical job duties of a Coreroom Foundry Laborer?

Coreroom Foundry Laborers typically prepare sand, operate core-making machines, inspect molds and cores, assemble and disassemble molds, operate molding machines, remove castings from molds, and grind and finish castings.

What are the educational requirements for becoming a Coreroom Foundry Laborer?

Most Coreroom Foundry Laborers have a high school diploma or equivalent, although some employers may require an associate degree in manufacturing technology or a related field.

What are the career prospects for Coreroom Foundry Laborers?

Coreroom Foundry Laborers can advance to positions such as Foundry Supervisor, Quality Control Inspector, or Production Manager.

What are the salary expectations for Coreroom Foundry Laborers?

The salary expectations for Coreroom Foundry Laborers vary depending on experience, location, and company size, but the average salary is around $40,000 per year.

What are the working conditions like for Coreroom Foundry Laborers?

Coreroom Foundry Laborers typically work in foundries, which can be hot, noisy, and dusty. They may also be required to work overtime or on weekends.

What are the safety precautions that Coreroom Foundry Laborers should take?

Coreroom Foundry Laborers should wear appropriate safety gear, such as gloves, safety glasses, and respirators, and follow all safety procedures.