Are you a seasoned Corrosion Control Engineer seeking a new career path? Discover our professionally built Corrosion Control Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

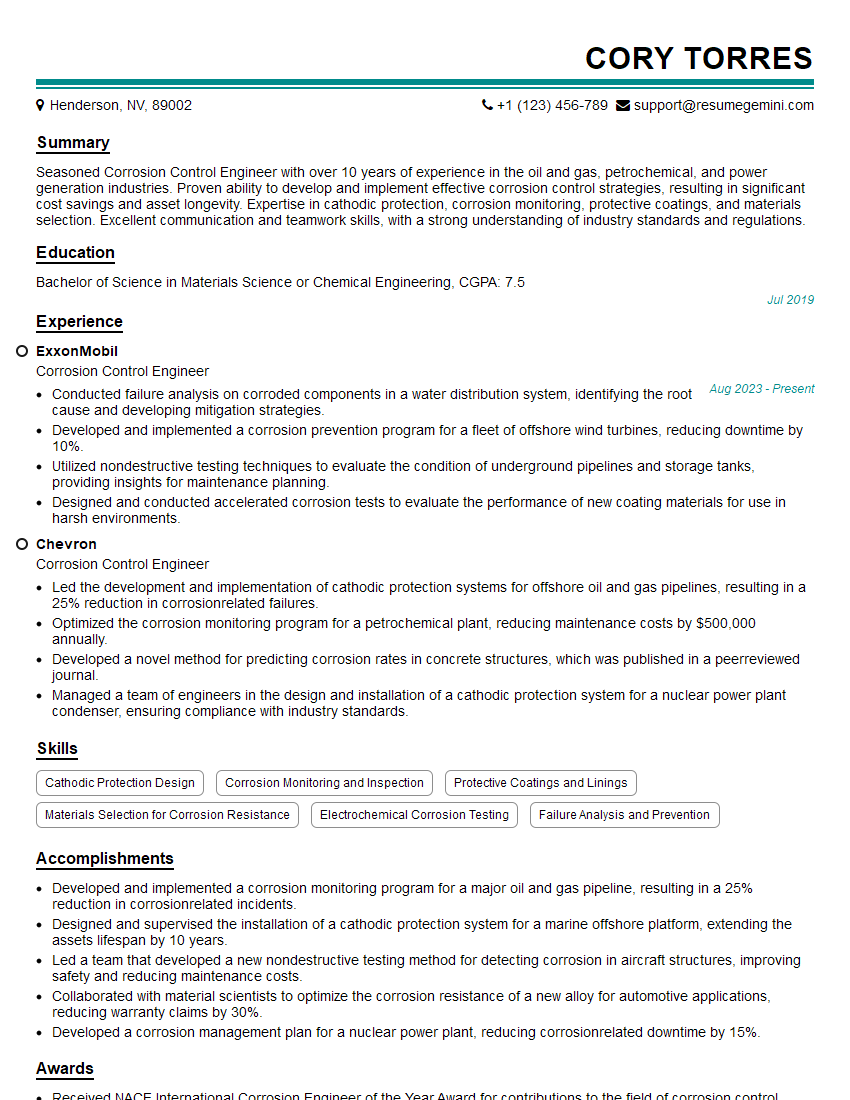

Cory Torres

Corrosion Control Engineer

Summary

Seasoned Corrosion Control Engineer with over 10 years of experience in the oil and gas, petrochemical, and power generation industries. Proven ability to develop and implement effective corrosion control strategies, resulting in significant cost savings and asset longevity. Expertise in cathodic protection, corrosion monitoring, protective coatings, and materials selection. Excellent communication and teamwork skills, with a strong understanding of industry standards and regulations.

Education

Bachelor of Science in Materials Science or Chemical Engineering

July 2019

Skills

- Cathodic Protection Design

- Corrosion Monitoring and Inspection

- Protective Coatings and Linings

- Materials Selection for Corrosion Resistance

- Electrochemical Corrosion Testing

- Failure Analysis and Prevention

Work Experience

Corrosion Control Engineer

- Conducted failure analysis on corroded components in a water distribution system, identifying the root cause and developing mitigation strategies.

- Developed and implemented a corrosion prevention program for a fleet of offshore wind turbines, reducing downtime by 10%.

- Utilized nondestructive testing techniques to evaluate the condition of underground pipelines and storage tanks, providing insights for maintenance planning.

- Designed and conducted accelerated corrosion tests to evaluate the performance of new coating materials for use in harsh environments.

Corrosion Control Engineer

- Led the development and implementation of cathodic protection systems for offshore oil and gas pipelines, resulting in a 25% reduction in corrosionrelated failures.

- Optimized the corrosion monitoring program for a petrochemical plant, reducing maintenance costs by $500,000 annually.

- Developed a novel method for predicting corrosion rates in concrete structures, which was published in a peerreviewed journal.

- Managed a team of engineers in the design and installation of a cathodic protection system for a nuclear power plant condenser, ensuring compliance with industry standards.

Accomplishments

- Developed and implemented a corrosion monitoring program for a major oil and gas pipeline, resulting in a 25% reduction in corrosionrelated incidents.

- Designed and supervised the installation of a cathodic protection system for a marine offshore platform, extending the assets lifespan by 10 years.

- Led a team that developed a new nondestructive testing method for detecting corrosion in aircraft structures, improving safety and reducing maintenance costs.

- Collaborated with material scientists to optimize the corrosion resistance of a new alloy for automotive applications, reducing warranty claims by 30%.

- Developed a corrosion management plan for a nuclear power plant, reducing corrosionrelated downtime by 15%.

Awards

- Received NACE International Corrosion Engineer of the Year Award for contributions to the field of corrosion control.

- Won the ASTM International Corrosion Award of Excellence for research on the electrochemical behavior of highperformance alloys.

- Recognized with the Association for Materials Protection and Performance (AMPP) Technical Achievement Award for innovative developments in corrosion control coatings.

- Received the NACE International Regional Innovation Award for developing a corrosionresistant coating for use in harsh environments.

Certificates

- NACE Certified Corrosion Specialist (CCS)

- NACE Certified Cathodic Protection Specialist (CP)

- NACE Certified Corrosion Inspector (CI)

- NACE Certified Protective Coatings Inspector (PC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Corrosion Control Engineer

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your experience in industry-specific software and technologies, such as cathodic protection design software and corrosion monitoring equipment.

- Emphasize your understanding of corrosion mechanisms and your ability to apply this knowledge to practical applications.

- Showcase your ability to work effectively in a team environment and manage multiple projects simultaneously.

Essential Experience Highlights for a Strong Corrosion Control Engineer Resume

- Design and implement corrosion control systems for pipelines, storage tanks, and other critical assets.

- Conduct corrosion monitoring and inspection programs to assess the condition of assets and identify potential risks.

- Develop and evaluate protective coatings and linings to mitigate corrosion.

- Select materials that are resistant to corrosion based on environmental conditions and operating requirements.

- Perform failure analysis to identify the root cause of corrosion-related failures and develop mitigation strategies.

- Collaborate with engineers, technicians, and contractors to ensure the successful implementation of corrosion control measures.

Frequently Asked Questions (FAQ’s) For Corrosion Control Engineer

What is the role of a Corrosion Control Engineer?

A Corrosion Control Engineer is responsible for developing and implementing strategies to prevent and mitigate corrosion in various industries, including oil and gas, petrochemical, power generation, and manufacturing. They design and install cathodic protection systems, conduct corrosion monitoring and inspection programs, evaluate protective coatings and linings, and select corrosion-resistant materials.

What are the key skills required for a Corrosion Control Engineer?

Essential skills for a Corrosion Control Engineer include: cathodic protection design, corrosion monitoring and inspection, protective coatings and linings, materials selection for corrosion resistance, electrochemical corrosion testing, failure analysis and prevention, and project management.

What industries employ Corrosion Control Engineers?

Corrosion Control Engineers are employed in a wide range of industries, including oil and gas, petrochemical, power generation, manufacturing, transportation, and water treatment. They play a critical role in protecting assets from the damaging effects of corrosion.

What are the career prospects for Corrosion Control Engineers?

Corrosion Control Engineers are in high demand due to the increasing need for corrosion prevention and mitigation in various industries. They have opportunities for advancement to senior-level positions, such as Corrosion Manager or Chief Corrosion Engineer.

What is the salary range for Corrosion Control Engineers?

The salary range for Corrosion Control Engineers varies depending on experience, industry, and location. According to Indeed, the average salary for Corrosion Control Engineers in the United States is around $95,000 per year.

What are the challenges faced by Corrosion Control Engineers?

Corrosion Control Engineers face challenges related to the complex nature of corrosion, the variety of materials and environments they encounter, and the need to balance cost-effectiveness with safety and environmental regulations.

What are the latest advancements in corrosion control?

Recent advancements in corrosion control include the development of new corrosion-resistant materials, improved cathodic protection techniques, and advanced non-destructive testing methods. Corrosion Control Engineers are continuously exploring and implementing these advancements to improve the performance and longevity of critical assets.