Are you a seasoned Cracking Machine Operator seeking a new career path? Discover our professionally built Cracking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

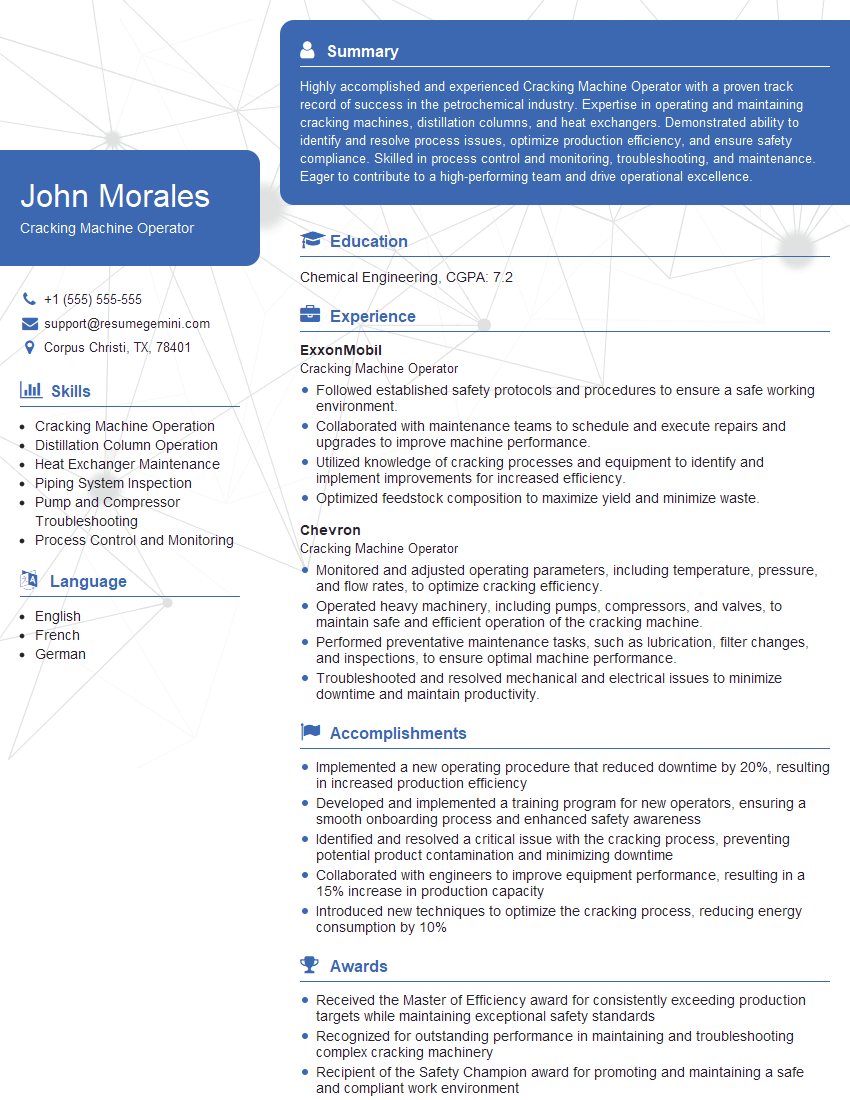

John Morales

Cracking Machine Operator

Summary

Highly accomplished and experienced Cracking Machine Operator with a proven track record of success in the petrochemical industry. Expertise in operating and maintaining cracking machines, distillation columns, and heat exchangers. Demonstrated ability to identify and resolve process issues, optimize production efficiency, and ensure safety compliance. Skilled in process control and monitoring, troubleshooting, and maintenance. Eager to contribute to a high-performing team and drive operational excellence.

Education

Chemical Engineering

October 2018

Skills

- Cracking Machine Operation

- Distillation Column Operation

- Heat Exchanger Maintenance

- Piping System Inspection

- Pump and Compressor Troubleshooting

- Process Control and Monitoring

Work Experience

Cracking Machine Operator

- Followed established safety protocols and procedures to ensure a safe working environment.

- Collaborated with maintenance teams to schedule and execute repairs and upgrades to improve machine performance.

- Utilized knowledge of cracking processes and equipment to identify and implement improvements for increased efficiency.

- Optimized feedstock composition to maximize yield and minimize waste.

Cracking Machine Operator

- Monitored and adjusted operating parameters, including temperature, pressure, and flow rates, to optimize cracking efficiency.

- Operated heavy machinery, including pumps, compressors, and valves, to maintain safe and efficient operation of the cracking machine.

- Performed preventative maintenance tasks, such as lubrication, filter changes, and inspections, to ensure optimal machine performance.

- Troubleshooted and resolved mechanical and electrical issues to minimize downtime and maintain productivity.

Accomplishments

- Implemented a new operating procedure that reduced downtime by 20%, resulting in increased production efficiency

- Developed and implemented a training program for new operators, ensuring a smooth onboarding process and enhanced safety awareness

- Identified and resolved a critical issue with the cracking process, preventing potential product contamination and minimizing downtime

- Collaborated with engineers to improve equipment performance, resulting in a 15% increase in production capacity

- Introduced new techniques to optimize the cracking process, reducing energy consumption by 10%

Awards

- Received the Master of Efficiency award for consistently exceeding production targets while maintaining exceptional safety standards

- Recognized for outstanding performance in maintaining and troubleshooting complex cracking machinery

- Recipient of the Safety Champion award for promoting and maintaining a safe and compliant work environment

- Commended for exceptional attention to detail and accuracy in maintaining and monitoring cracking equipment

Certificates

- Certified Cracking Machine Operator (CCMO)

- Certified Petroleum Professional (CPP)

- Certified Maintenance and Reliability Technician (CMRT)

- OSHA 30Hour Hazardous Waste Operations and Emergency Response (HAZWOPER)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cracking Machine Operator

- Highlight your experience in operating and maintaining cracking machines, distillation columns, and other related equipment.

- Quantify your accomplishments using specific metrics, such as reduced downtime, increased production, and energy savings.

- Demonstrate your problem-solving skills and ability to identify and resolve process issues.

- Emphasize your teamwork and collaboration abilities, as well as your commitment to safety.

Essential Experience Highlights for a Strong Cracking Machine Operator Resume

- Operate cracking machines to convert hydrocarbons into valuable products.

- Monitor and control process parameters, including temperature, pressure, and flow rates.

- Troubleshoot and resolve operational issues to minimize downtime and ensure smooth production.

- Perform preventive and corrective maintenance on cracking machines, distillation columns, and heat exchangers.

- Inspect piping systems and pumps to ensure integrity and prevent leaks.

- Collaborate with engineers and technicians to improve equipment performance and optimize processes.

- Adhere to safety protocols and regulations to ensure a safe working environment.

Frequently Asked Questions (FAQ’s) For Cracking Machine Operator

What are the key skills required to be a successful Cracking Machine Operator?

Key skills include: Cracking Machine Operation, Distillation Column Operation, Heat Exchanger Maintenance, Piping System Inspection, Pump and Compressor Troubleshooting, Process Control and Monitoring.

What is the work environment of a Cracking Machine Operator like?

Cracking Machine Operators typically work in industrial settings, such as petrochemical plants or refineries. The work can be physically demanding and may involve working in hazardous environments.

What are the career prospects for a Cracking Machine Operator?

With experience and additional training, Cracking Machine Operators can advance to positions such as Process Engineer, Production Supervisor, or Plant Manager.

What is the average salary for a Cracking Machine Operator?

The average salary for a Cracking Machine Operator varies depending on factors such as experience, location, and industry. According to Salary.com, the average salary range is between $60,000 and $90,000 per year.

What are the educational requirements for a Cracking Machine Operator?

While there are no formal educational requirements, most Cracking Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with a degree in Chemical Engineering or a related field.

What are the certifications available for a Cracking Machine Operator?

There are several certifications available for Cracking Machine Operators, including: Certified Process Operator (CPO) from the American Institute of Chemical Engineers (AIChE) and Certified Maintenance and Reliability Technician (CMRT) from the Society for Maintenance and Reliability Professionals (SMRP).