Are you a seasoned Crackling Press Operator seeking a new career path? Discover our professionally built Crackling Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

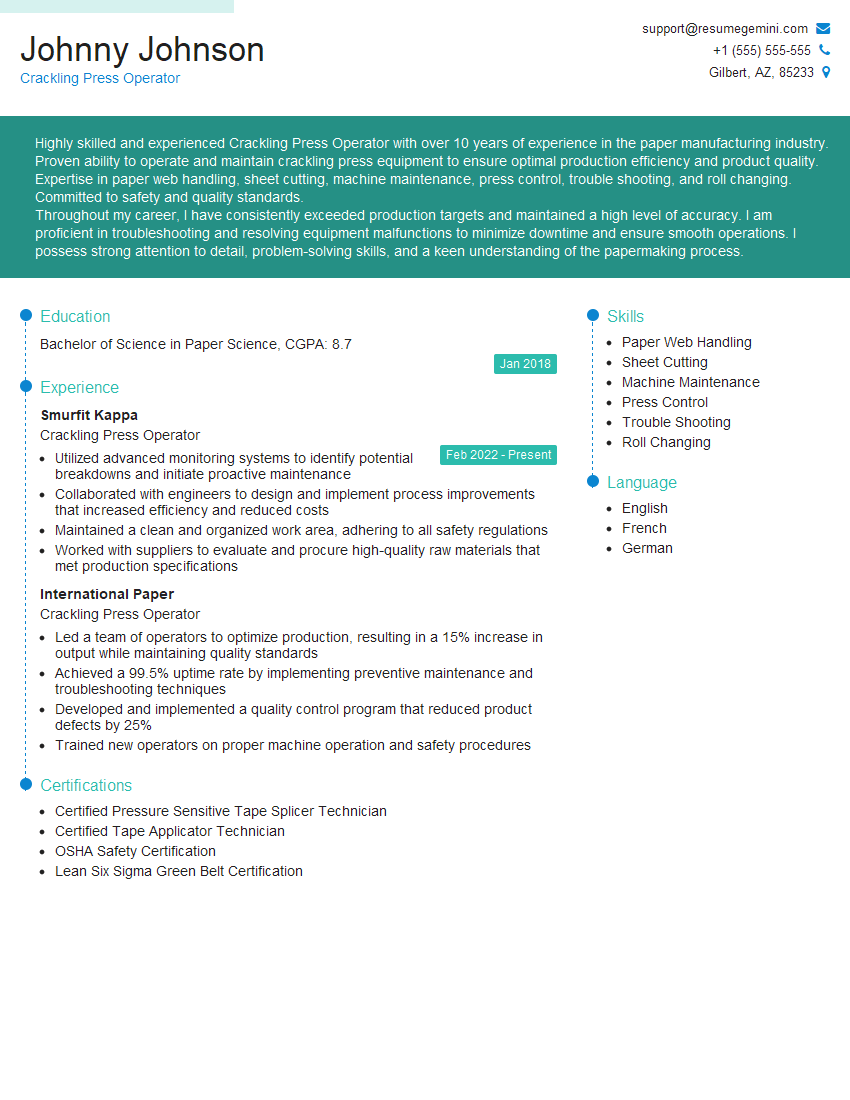

Johnny Johnson

Crackling Press Operator

Summary

Highly skilled and experienced Crackling Press Operator with over 10 years of experience in the paper manufacturing industry. Proven ability to operate and maintain crackling press equipment to ensure optimal production efficiency and product quality. Expertise in paper web handling, sheet cutting, machine maintenance, press control, trouble shooting, and roll changing. Committed to safety and quality standards.

Throughout my career, I have consistently exceeded production targets and maintained a high level of accuracy. I am proficient in troubleshooting and resolving equipment malfunctions to minimize downtime and ensure smooth operations. I possess strong attention to detail, problem-solving skills, and a keen understanding of the papermaking process.

Education

Bachelor of Science in Paper Science

January 2018

Skills

- Paper Web Handling

- Sheet Cutting

- Machine Maintenance

- Press Control

- Trouble Shooting

- Roll Changing

Work Experience

Crackling Press Operator

- Utilized advanced monitoring systems to identify potential breakdowns and initiate proactive maintenance

- Collaborated with engineers to design and implement process improvements that increased efficiency and reduced costs

- Maintained a clean and organized work area, adhering to all safety regulations

- Worked with suppliers to evaluate and procure high-quality raw materials that met production specifications

Crackling Press Operator

- Led a team of operators to optimize production, resulting in a 15% increase in output while maintaining quality standards

- Achieved a 99.5% uptime rate by implementing preventive maintenance and troubleshooting techniques

- Developed and implemented a quality control program that reduced product defects by 25%

- Trained new operators on proper machine operation and safety procedures

Certificates

- Certified Pressure Sensitive Tape Splicer Technician

- Certified Tape Applicator Technician

- OSHA Safety Certification

- Lean Six Sigma Green Belt Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crackling Press Operator

- Highlight your technical skills and experience in operating and maintaining crackling press equipment.

- Quantify your accomplishments by providing specific metrics and results.

- Demonstrate your commitment to safety and quality by mentioning any relevant certifications or training.

- Showcase your problem-solving abilities and troubleshooting experience.

Essential Experience Highlights for a Strong Crackling Press Operator Resume

- Operate and monitor crackling press equipment to produce high-quality paper products.

- Handle paper webs with precision to ensure proper alignment and tension.

- Cut and trim paper sheets to meet precise specifications using various cutting tools.

- Perform regular maintenance and inspection of crackling press equipment to ensure optimal performance.

- Troubleshoot and resolve equipment malfunctions promptly to minimize downtime.

- Change rolls of paper as needed to maintain continuous production.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Crackling Press Operator

What is the role of a Crackling Press Operator?

A Crackling Press Operator is responsible for operating and maintaining crackling press equipment used in the paper manufacturing industry. They ensure the efficient production of high-quality paper products by handling paper webs, cutting and trimming sheets, performing maintenance, troubleshooting malfunctions, and changing rolls of paper.

What are the key skills required for a Crackling Press Operator?

Key skills for a Crackling Press Operator include paper web handling, sheet cutting, machine maintenance, press control, troubleshooting, roll changing, attention to detail, problem-solving, and a basic understanding of the papermaking process.

What industries employ Crackling Press Operators?

Crackling Press Operators are primarily employed in the paper manufacturing industry, particularly in mills that specialize in the production of various types of paper products.

Is a formal education required to become a Crackling Press Operator?

While a formal education is not always required, most employers prefer candidates with a high school diploma or equivalent and some experience in the paper manufacturing industry. Some companies may also offer on-the-job training for entry-level operators.

What career advancement opportunities are available for Crackling Press Operators?

With experience and additional training, Crackling Press Operators can advance to supervisory roles, such as Pressroom Supervisor or Production Manager. They may also specialize in specific areas of paper manufacturing, such as quality control or maintenance.

What is the average salary for a Crackling Press Operator?

The average salary for a Crackling Press Operator varies depending on factors such as experience, location, and employer. According to Indeed, the average salary for a Crackling Press Operator in the United States as of 2023 is around $60,000 per year.

What is the job outlook for Crackling Press Operators?

The job outlook for Crackling Press Operators is expected to remain stable in the coming years. As the demand for paper products continues, there will be a need for skilled operators to maintain and operate crackling press equipment.