Are you a seasoned Crane Ladle Person seeking a new career path? Discover our professionally built Crane Ladle Person Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

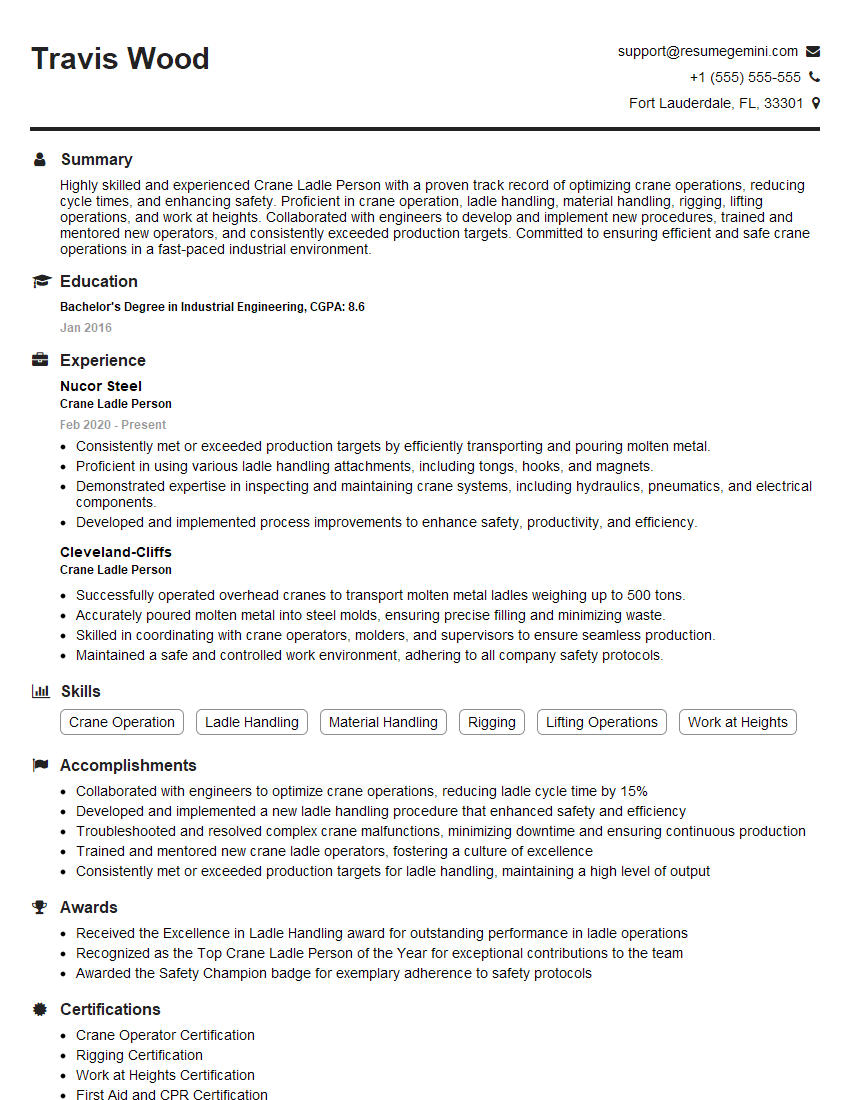

Travis Wood

Crane Ladle Person

Summary

Highly skilled and experienced Crane Ladle Person with a proven track record of optimizing crane operations, reducing cycle times, and enhancing safety. Proficient in crane operation, ladle handling, material handling, rigging, lifting operations, and work at heights. Collaborated with engineers to develop and implement new procedures, trained and mentored new operators, and consistently exceeded production targets. Committed to ensuring efficient and safe crane operations in a fast-paced industrial environment.

Education

Bachelor’s Degree in Industrial Engineering

January 2016

Skills

- Crane Operation

- Ladle Handling

- Material Handling

- Rigging

- Lifting Operations

- Work at Heights

Work Experience

Crane Ladle Person

- Consistently met or exceeded production targets by efficiently transporting and pouring molten metal.

- Proficient in using various ladle handling attachments, including tongs, hooks, and magnets.

- Demonstrated expertise in inspecting and maintaining crane systems, including hydraulics, pneumatics, and electrical components.

- Developed and implemented process improvements to enhance safety, productivity, and efficiency.

Crane Ladle Person

- Successfully operated overhead cranes to transport molten metal ladles weighing up to 500 tons.

- Accurately poured molten metal into steel molds, ensuring precise filling and minimizing waste.

- Skilled in coordinating with crane operators, molders, and supervisors to ensure seamless production.

- Maintained a safe and controlled work environment, adhering to all company safety protocols.

Accomplishments

- Collaborated with engineers to optimize crane operations, reducing ladle cycle time by 15%

- Developed and implemented a new ladle handling procedure that enhanced safety and efficiency

- Troubleshooted and resolved complex crane malfunctions, minimizing downtime and ensuring continuous production

- Trained and mentored new crane ladle operators, fostering a culture of excellence

- Consistently met or exceeded production targets for ladle handling, maintaining a high level of output

Awards

- Received the Excellence in Ladle Handling award for outstanding performance in ladle operations

- Recognized as the Top Crane Ladle Person of the Year for exceptional contributions to the team

- Awarded the Safety Champion badge for exemplary adherence to safety protocols

Certificates

- Crane Operator Certification

- Rigging Certification

- Work at Heights Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crane Ladle Person

- Highlight your experience and skills in crane operation, ladle handling, and material handling.

- Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your commitment to safety and your ability to work effectively in a team environment.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Crane Ladle Person Resume

- Operate cranes to hoist and transport molten steel ladles safely and efficiently

- Collaborate with engineers to optimize crane operations and reduce cycle times

- Develop and implement new ladle handling procedures to enhance safety and efficiency

- Troubleshoot and resolve crane malfunctions to minimize downtime and ensure continuous production

- Train and mentor new crane ladle operators to foster a culture of excellence

- Maintain a clean and organized work area to ensure safety and productivity

- Adhere to all safety regulations and company policies

Frequently Asked Questions (FAQ’s) For Crane Ladle Person

What is the primary responsibility of a Crane Ladle Person?

The primary responsibility of a Crane Ladle Person is to safely and efficiently operate cranes to hoist and transport molten steel ladles in an industrial setting.

What skills are required to be a successful Crane Ladle Person?

To be successful in this role, one typically needs to have strong crane operation skills, ladle handling experience, and a solid understanding of material handling principles.

What is the work environment of a Crane Ladle Person like?

Crane Ladle Persons typically work in industrial settings, such as steel mills or foundries, and operate cranes in hot and potentially hazardous environments.

What are the career prospects for a Crane Ladle Person?

With experience and additional training, Crane Ladle Persons can advance to supervisory or management roles within the steel industry.

Is certification required to be a Crane Ladle Person?

Certification is not typically required, but obtaining industry-recognized certifications can enhance your credibility and career prospects.

What are the physical demands of being a Crane Ladle Person?

This role requires physical strength and stamina, as well as the ability to work in high temperatures and confined spaces.

What is the salary range for a Crane Ladle Person?

The salary range for Crane Ladle Persons can vary depending on experience, location, and employer. According to Indeed, the average salary in the United States is around $65,000 per year.

What is the job outlook for Crane Ladle Persons?

The job outlook for Crane Ladle Persons is expected to be stable in the coming years due to the ongoing demand for steel and the need for skilled operators in the industry.