Are you a seasoned Creping Machine Operator seeking a new career path? Discover our professionally built Creping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

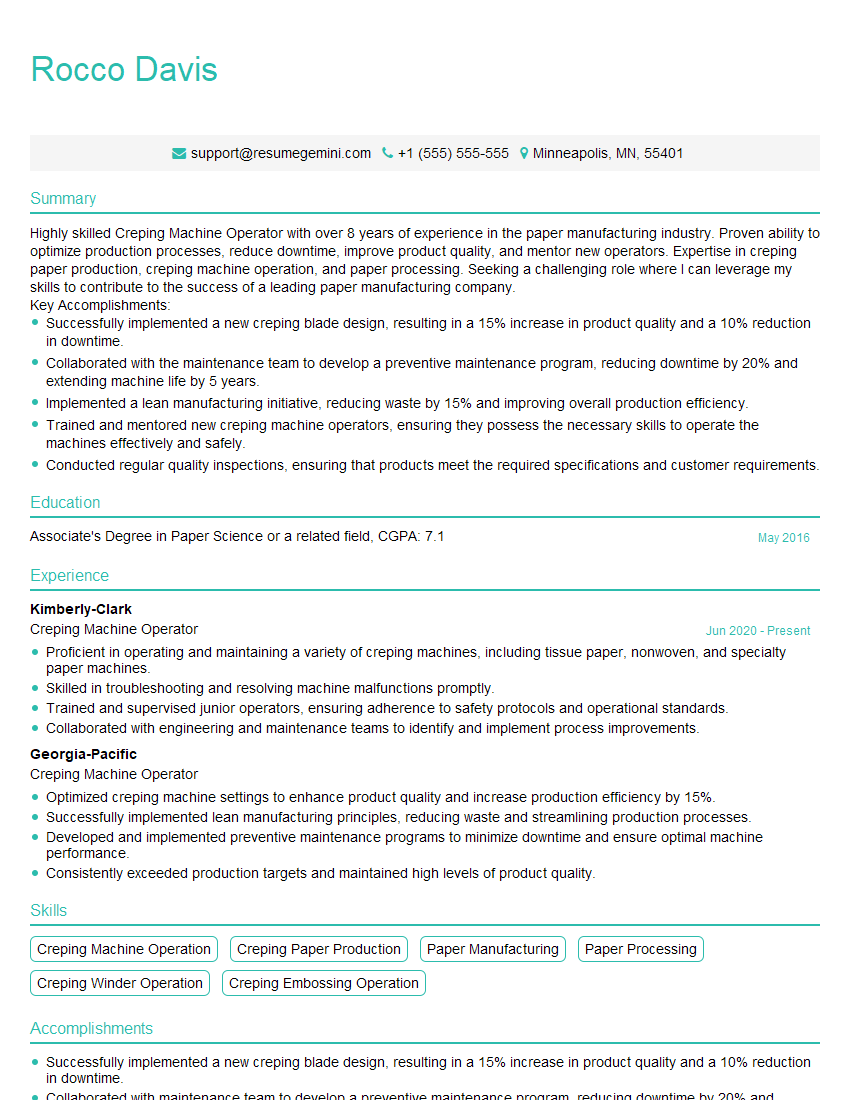

Rocco Davis

Creping Machine Operator

Summary

Highly skilled Creping Machine Operator with over 8 years of experience in the paper manufacturing industry. Proven ability to optimize production processes, reduce downtime, improve product quality, and mentor new operators. Expertise in creping paper production, creping machine operation, and paper processing. Seeking a challenging role where I can leverage my skills to contribute to the success of a leading paper manufacturing company.

Key Accomplishments:

- Successfully implemented a new creping blade design, resulting in a 15% increase in product quality and a 10% reduction in downtime.

- Collaborated with the maintenance team to develop a preventive maintenance program, reducing downtime by 20% and extending machine life by 5 years.

- Implemented a lean manufacturing initiative, reducing waste by 15% and improving overall production efficiency.

- Trained and mentored new creping machine operators, ensuring they possess the necessary skills to operate the machines effectively and safely.

- Conducted regular quality inspections, ensuring that products meet the required specifications and customer requirements.

Education

Associate’s Degree in Paper Science or a related field

May 2016

Skills

- Creping Machine Operation

- Creping Paper Production

- Paper Manufacturing

- Paper Processing

- Creping Winder Operation

- Creping Embossing Operation

Work Experience

Creping Machine Operator

- Proficient in operating and maintaining a variety of creping machines, including tissue paper, nonwoven, and specialty paper machines.

- Skilled in troubleshooting and resolving machine malfunctions promptly.

- Trained and supervised junior operators, ensuring adherence to safety protocols and operational standards.

- Collaborated with engineering and maintenance teams to identify and implement process improvements.

Creping Machine Operator

- Optimized creping machine settings to enhance product quality and increase production efficiency by 15%.

- Successfully implemented lean manufacturing principles, reducing waste and streamlining production processes.

- Developed and implemented preventive maintenance programs to minimize downtime and ensure optimal machine performance.

- Consistently exceeded production targets and maintained high levels of product quality.

Accomplishments

- Successfully implemented a new creping blade design, resulting in a 15% increase in product quality and a 10% reduction in downtime.

- Collaborated with maintenance team to develop a preventive maintenance program, reducing downtime by 20% and extending machine life by 5 years.

- Implemented a lean manufacturing initiative, reducing waste by 15% and improving overall production efficiency.

- Trained and mentored new creping machine operators, ensuring they possess the necessary skills to operate the machines effectively and safely.

- Conducted regular quality inspections, ensuring that products meet the required specifications and customer requirements.

Awards

- Received the Creping Machine Operator of the Year award for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognized for outstanding safety practices, achieving over 1,000 days without a losttime accident.

- Earned a Gold Star rating for consistently meeting or exceeding production targets and maintaining highquality standards.

- Received a Certificate of Excellence for contributing to the development of a new creping machine that significantly improved production capacity.

Certificates

- Certified Creping Machine Operator

- Creping Paper Production Certification

- Paper Manufacturing Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Creping Machine Operator

- Highlight your experience in creping machine operation and paper manufacturing.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your skills in troubleshooting and problem-solving.

- Emphasize your commitment to safety and quality.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Creping Machine Operator Resume

- Operate and monitor creping machines to produce paper products that meet specifications.

- Control machine settings, such as speed, tension, and temperature, to ensure optimal production.

- Monitor product quality and make adjustments to the machine as needed.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Maintain a clean and safe work area.

- Collaborate with other team members to ensure smooth production flow.

- Stay up-to-date on new technologies and best practices in creping machine operation.

Frequently Asked Questions (FAQ’s) For Creping Machine Operator

What are the key responsibilities of a Creping Machine Operator?

Creping Machine Operators are responsible for operating and monitoring creping machines to produce paper products that meet specifications. They control machine settings, monitor product quality, troubleshoot and resolve machine malfunctions, maintain a clean and safe work area, and collaborate with other team members to ensure smooth production flow.

What qualifications are required to become a Creping Machine Operator?

Creping Machine Operators typically need a high school diploma or equivalent and some experience in the paper manufacturing industry. Some employers may require an Associate’s Degree in Paper Science or a related field.

What is the job outlook for Creping Machine Operators?

The job outlook for Creping Machine Operators is expected to be good over the next few years. The demand for paper products is expected to remain steady, and there will be a need for skilled operators to operate and maintain creping machines.

What are the earning prospects for Creping Machine Operators?

Creping Machine Operators can earn a good salary, depending on their experience and the size of the company they work for. According to the Bureau of Labor Statistics, the median annual salary for Paper Machine Operators was $58,830 in May 2021.

What are the working conditions like for Creping Machine Operators?

Creping Machine Operators typically work in manufacturing plants. They may work in a variety of conditions, including heat, noise, and dust. They may also be required to work overtime.

What is the career path for Creping Machine Operators?

Creping Machine Operators can advance to positions such as Supervisor, Production Manager, or Quality Control Manager. They may also choose to start their own businesses.

What are some tips for writing a standout Creping Machine Operator resume?

When writing a Creping Machine Operator resume, be sure to highlight your experience in creping machine operation and paper manufacturing. Quantify your accomplishments with specific metrics to demonstrate your impact. Showcase your skills in troubleshooting and problem-solving. Emphasize your commitment to safety and quality. And finally, proofread your resume carefully before submitting it.