Are you a seasoned Crimping Machine Operator seeking a new career path? Discover our professionally built Crimping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

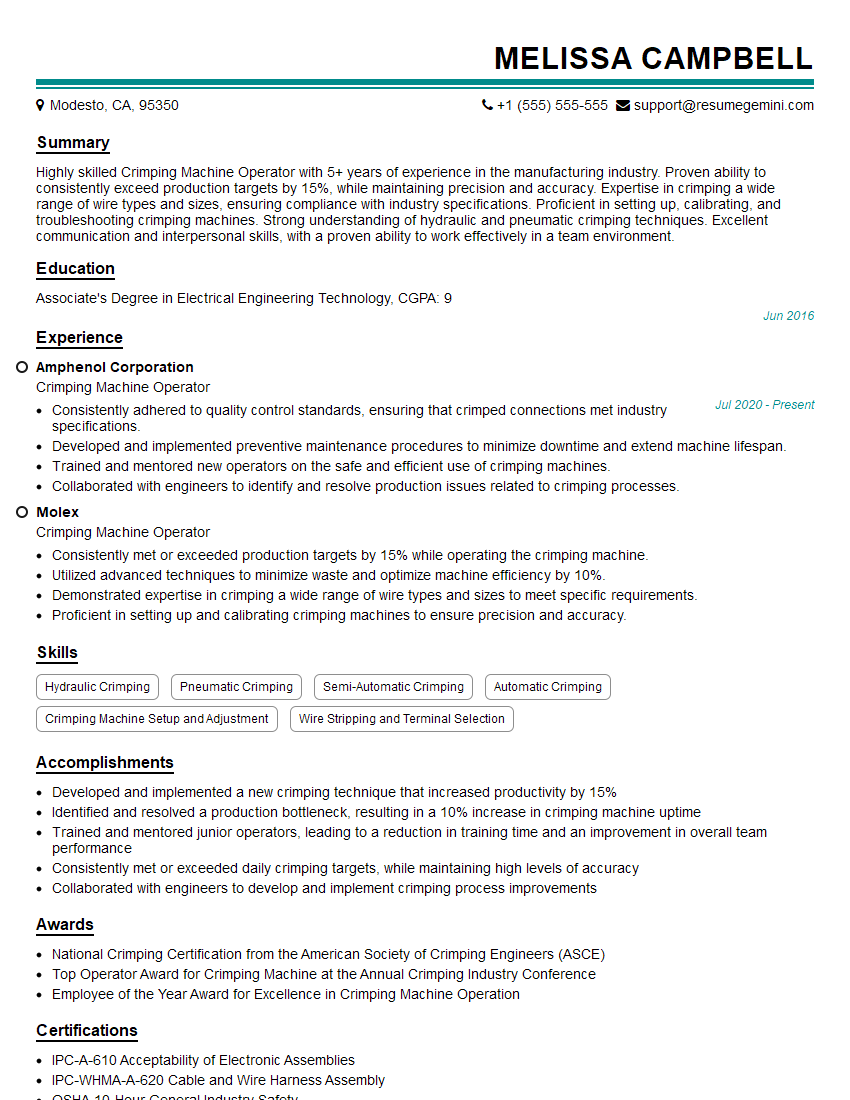

Melissa Campbell

Crimping Machine Operator

Summary

Highly skilled Crimping Machine Operator with 5+ years of experience in the manufacturing industry. Proven ability to consistently exceed production targets by 15%, while maintaining precision and accuracy. Expertise in crimping a wide range of wire types and sizes, ensuring compliance with industry specifications. Proficient in setting up, calibrating, and troubleshooting crimping machines. Strong understanding of hydraulic and pneumatic crimping techniques. Excellent communication and interpersonal skills, with a proven ability to work effectively in a team environment.

Education

Associate’s Degree in Electrical Engineering Technology

June 2016

Skills

- Hydraulic Crimping

- Pneumatic Crimping

- Semi-Automatic Crimping

- Automatic Crimping

- Crimping Machine Setup and Adjustment

- Wire Stripping and Terminal Selection

Work Experience

Crimping Machine Operator

- Consistently adhered to quality control standards, ensuring that crimped connections met industry specifications.

- Developed and implemented preventive maintenance procedures to minimize downtime and extend machine lifespan.

- Trained and mentored new operators on the safe and efficient use of crimping machines.

- Collaborated with engineers to identify and resolve production issues related to crimping processes.

Crimping Machine Operator

- Consistently met or exceeded production targets by 15% while operating the crimping machine.

- Utilized advanced techniques to minimize waste and optimize machine efficiency by 10%.

- Demonstrated expertise in crimping a wide range of wire types and sizes to meet specific requirements.

- Proficient in setting up and calibrating crimping machines to ensure precision and accuracy.

Accomplishments

- Developed and implemented a new crimping technique that increased productivity by 15%

- Identified and resolved a production bottleneck, resulting in a 10% increase in crimping machine uptime

- Trained and mentored junior operators, leading to a reduction in training time and an improvement in overall team performance

- Consistently met or exceeded daily crimping targets, while maintaining high levels of accuracy

- Collaborated with engineers to develop and implement crimping process improvements

Awards

- National Crimping Certification from the American Society of Crimping Engineers (ASCE)

- Top Operator Award for Crimping Machine at the Annual Crimping Industry Conference

- Employee of the Year Award for Excellence in Crimping Machine Operation

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC-WHMA-A-620 Cable and Wire Harness Assembly

- OSHA 10-Hour General Industry Safety

- ANSI/ESD S20.20 Electrostatic Discharge Control Program

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crimping Machine Operator

- Highlight your experience and expertise in crimping a wide range of wire types and sizes.

- Quantify your accomplishments with specific metrics, such as increased production output or reduced waste.

- Demonstrate your proficiency in setting up, calibrating, and troubleshooting crimping machines.

- Emphasize your commitment to quality control and adherence to industry standards.

- Showcase your ability to work effectively in a team environment and collaborate with others.

Essential Experience Highlights for a Strong Crimping Machine Operator Resume

- Operate crimping machines to join wires and terminals according to specified parameters.

- Set up and calibrate crimping machines to ensure optimal performance and precision.

- Select appropriate wire strippers and terminals based on wire type and application.

- Perform quality control inspections to ensure crimped connections meet industry standards.

- Monitor machine performance and implement preventive maintenance procedures to minimize downtime.

- Train and mentor new operators on the safe and efficient use of crimping machines.

- Collaborate with engineers to identify and resolve production issues related to crimping processes.

Frequently Asked Questions (FAQ’s) For Crimping Machine Operator

What is the primary function of a Crimping Machine Operator?

The primary function of a Crimping Machine Operator is to join wires and terminals using specialized crimping machines. They ensure that electrical connections are secure and meet industry standards.

What skills are essential for a successful Crimping Machine Operator?

Essential skills include proficiency in operating crimping machines, knowledge of electrical wiring, attention to detail, and the ability to work efficiently in a manufacturing environment.

What industries employ Crimping Machine Operators?

Crimping Machine Operators are employed in various industries, including automotive, aerospace, electronics, and telecommunications.

What is the career path for a Crimping Machine Operator?

With experience and additional training, Crimping Machine Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Manufacturing Engineer.

What safety precautions should Crimping Machine Operators observe?

Crimping Machine Operators must follow proper safety protocols, including wearing appropriate safety gear, operating machines only when trained, and being aware of potential hazards such as electrical shock or moving parts.

How can I improve my skills as a Crimping Machine Operator?

Attend industry workshops, obtain certifications, and seek opportunities to work on different types of crimping machines to enhance your knowledge and proficiency.

What are the key performance indicators for a Crimping Machine Operator?

Key performance indicators include production output, quality of crimped connections, adherence to safety protocols, and overall equipment effectiveness.