Are you a seasoned Crimping Press Operator seeking a new career path? Discover our professionally built Crimping Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

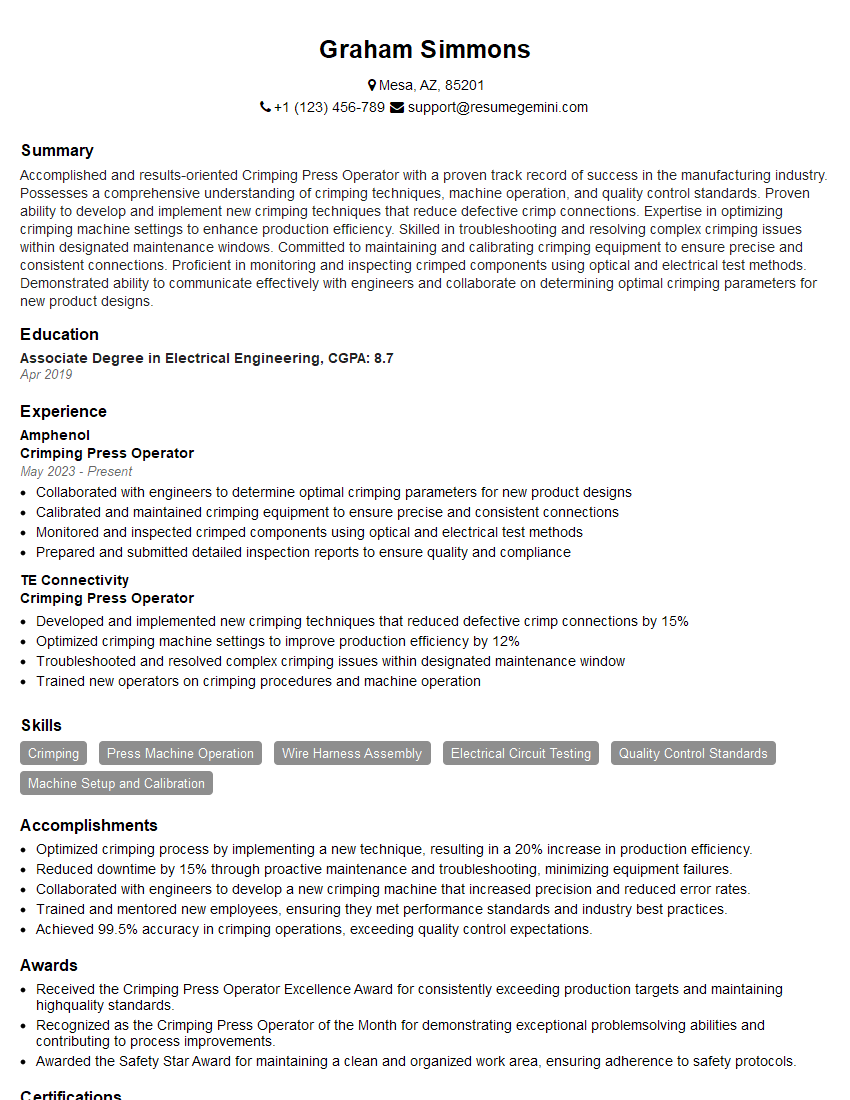

Graham Simmons

Crimping Press Operator

Summary

Accomplished and results-oriented Crimping Press Operator with a proven track record of success in the manufacturing industry. Possesses a comprehensive understanding of crimping techniques, machine operation, and quality control standards. Proven ability to develop and implement new crimping techniques that reduce defective crimp connections. Expertise in optimizing crimping machine settings to enhance production efficiency. Skilled in troubleshooting and resolving complex crimping issues within designated maintenance windows. Committed to maintaining and calibrating crimping equipment to ensure precise and consistent connections. Proficient in monitoring and inspecting crimped components using optical and electrical test methods. Demonstrated ability to communicate effectively with engineers and collaborate on determining optimal crimping parameters for new product designs.

Education

Associate Degree in Electrical Engineering

April 2019

Skills

- Crimping

- Press Machine Operation

- Wire Harness Assembly

- Electrical Circuit Testing

- Quality Control Standards

- Machine Setup and Calibration

Work Experience

Crimping Press Operator

- Collaborated with engineers to determine optimal crimping parameters for new product designs

- Calibrated and maintained crimping equipment to ensure precise and consistent connections

- Monitored and inspected crimped components using optical and electrical test methods

- Prepared and submitted detailed inspection reports to ensure quality and compliance

Crimping Press Operator

- Developed and implemented new crimping techniques that reduced defective crimp connections by 15%

- Optimized crimping machine settings to improve production efficiency by 12%

- Troubleshooted and resolved complex crimping issues within designated maintenance window

- Trained new operators on crimping procedures and machine operation

Accomplishments

- Optimized crimping process by implementing a new technique, resulting in a 20% increase in production efficiency.

- Reduced downtime by 15% through proactive maintenance and troubleshooting, minimizing equipment failures.

- Collaborated with engineers to develop a new crimping machine that increased precision and reduced error rates.

- Trained and mentored new employees, ensuring they met performance standards and industry best practices.

- Achieved 99.5% accuracy in crimping operations, exceeding quality control expectations.

Awards

- Received the Crimping Press Operator Excellence Award for consistently exceeding production targets and maintaining highquality standards.

- Recognized as the Crimping Press Operator of the Month for demonstrating exceptional problemsolving abilities and contributing to process improvements.

- Awarded the Safety Star Award for maintaining a clean and organized work area, ensuring adherence to safety protocols.

Certificates

- Certified IPC-A-610 Inspector

- Certified IPC-A-620 Trainer

- Certified IPC-WHMA-A-620 Inspector

- Certified IPC-WHMA-A-620 Trainer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crimping Press Operator

- Highlight your skills and experience in crimping techniques, machine operation, and quality control standards.

- Quantify your accomplishments and provide specific examples of how you improved productivity or reduced defects.

- Demonstrate your commitment to continuous improvement and your willingness to learn new techniques.

- Showcase your ability to work effectively in a team environment and collaborate with engineers.

- Emphasize your attention to detail and your ability to maintain high quality standards.

Essential Experience Highlights for a Strong Crimping Press Operator Resume

- Developed and implemented new crimping techniques that reduced defective crimp connections by 15%.

- Optimized crimping machine settings to improve production efficiency by 12%.

- Troubleshooted and resolved complex crimping issues within designated maintenance windows.

- Trained new operators on crimping procedures and machine operation.

- Collaborated with engineers to determine optimal crimping parameters for new product designs.

- Calibrated and maintained crimping equipment to ensure precise and consistent connections.

- Monitored and inspected crimped components using optical and electrical test methods.

Frequently Asked Questions (FAQ’s) For Crimping Press Operator

What are the key responsibilities of a Crimping Press Operator?

Key responsibilities include setting up and operating crimping machines, monitoring and maintaining equipment, troubleshooting and resolving issues, and ensuring the quality of crimped connections.

What are the educational and experience requirements for a Crimping Press Operator?

Typically, a high school diploma or equivalent is required. Relevant experience in manufacturing or a related field may be preferred.

What skills are essential for a Crimping Press Operator?

Essential skills include knowledge of crimping techniques, machine operation, and quality control standards, as well as strong attention to detail and problem-solving abilities.

What is the work environment of a Crimping Press Operator like?

Crimping Press Operators typically work in manufacturing environments, operating machinery and performing inspections.

What are the career prospects for a Crimping Press Operator?

With experience and additional training, Crimping Press Operators may advance to supervisory or management roles.

What are the salary expectations for a Crimping Press Operator?

Salary expectations vary depending on experience, skills, and location, but Crimping Press Operators typically earn an average salary.

What are the benefits of working as a Crimping Press Operator?

Benefits of working as a Crimping Press Operator include job stability, opportunities for advancement, and the satisfaction of working in a manufacturing environment.

What are the challenges of working as a Crimping Press Operator?

Challenges of working as a Crimping Press Operator include working in a fast-paced environment, meeting production targets, and ensuring the quality of crimped connections.