Are you a seasoned Croze Machine Operator seeking a new career path? Discover our professionally built Croze Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

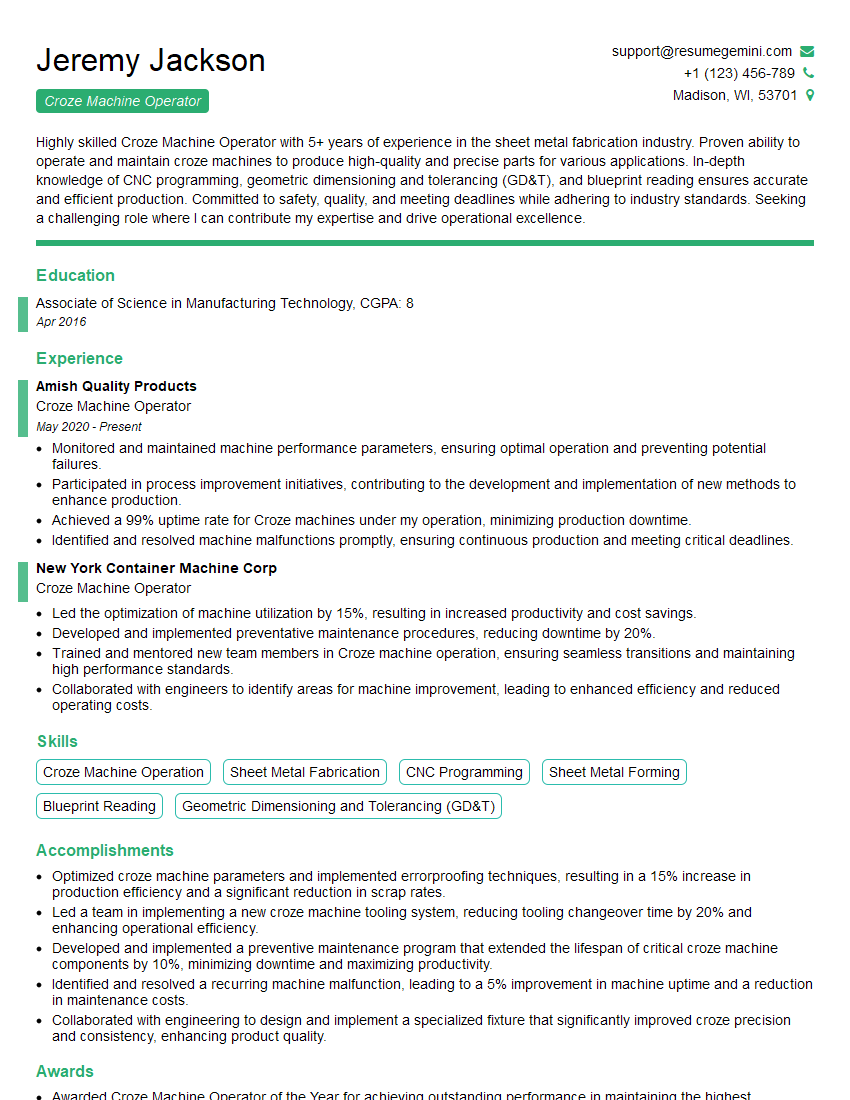

Jeremy Jackson

Croze Machine Operator

Summary

Highly skilled Croze Machine Operator with 5+ years of experience in the sheet metal fabrication industry. Proven ability to operate and maintain croze machines to produce high-quality and precise parts for various applications. In-depth knowledge of CNC programming, geometric dimensioning and tolerancing (GD&T), and blueprint reading ensures accurate and efficient production. Committed to safety, quality, and meeting deadlines while adhering to industry standards. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate of Science in Manufacturing Technology

April 2016

Skills

- Croze Machine Operation

- Sheet Metal Fabrication

- CNC Programming

- Sheet Metal Forming

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Croze Machine Operator

- Monitored and maintained machine performance parameters, ensuring optimal operation and preventing potential failures.

- Participated in process improvement initiatives, contributing to the development and implementation of new methods to enhance production.

- Achieved a 99% uptime rate for Croze machines under my operation, minimizing production downtime.

- Identified and resolved machine malfunctions promptly, ensuring continuous production and meeting critical deadlines.

Croze Machine Operator

- Led the optimization of machine utilization by 15%, resulting in increased productivity and cost savings.

- Developed and implemented preventative maintenance procedures, reducing downtime by 20%.

- Trained and mentored new team members in Croze machine operation, ensuring seamless transitions and maintaining high performance standards.

- Collaborated with engineers to identify areas for machine improvement, leading to enhanced efficiency and reduced operating costs.

Accomplishments

- Optimized croze machine parameters and implemented errorproofing techniques, resulting in a 15% increase in production efficiency and a significant reduction in scrap rates.

- Led a team in implementing a new croze machine tooling system, reducing tooling changeover time by 20% and enhancing operational efficiency.

- Developed and implemented a preventive maintenance program that extended the lifespan of critical croze machine components by 10%, minimizing downtime and maximizing productivity.

- Identified and resolved a recurring machine malfunction, leading to a 5% improvement in machine uptime and a reduction in maintenance costs.

- Collaborated with engineering to design and implement a specialized fixture that significantly improved croze precision and consistency, enhancing product quality.

Awards

- Awarded Croze Machine Operator of the Year for achieving outstanding performance in maintaining the highest production rate while ensuring zero defects.

- Received a Safety Excellence Award for maintaining an impeccable safety record with no incidents or accidents during a threeyear operating period.

- Recognized as a Master Croze Machine Operator for demonstrating exceptional skills, knowledge, and expertise in operating and maintaining croze machinery.

- Awarded Croze Machine Innovation Award for proposing and implementing a novel solution to improve product quality and reduce production costs.

Certificates

- Certified Croze Machine Operator (CCMO)

- Certified Sheet Metal Fabricator (CSMF)

- Certified Welder (CW)

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Croze Machine Operator

- Tailor your resume to each specific job application, highlighting the skills and experience most relevant to the position.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

- Consider including a cover letter that introduces you, summarizes your qualifications, and expresses your interest in the role.

Essential Experience Highlights for a Strong Croze Machine Operator Resume

- Set up, operate, and maintain croze machines following established work orders and blueprints.

- Program CNC controllers and optimize cutting parameters to achieve desired results.

- Inspect and measure parts using precision instruments to ensure they meet specifications and GD&T requirements.

- Perform routine maintenance and troubleshooting to minimize downtime and maintain equipment efficiency.

- Collaborate with engineers and other team members to develop and improve manufacturing processes.

- Adhere to safety protocols, wear appropriate PPE, and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Croze Machine Operator

What is a Croze Machine Operator?

A Croze Machine Operator is responsible for operating and maintaining croze machines, which are used to form and shape sheet metal parts. They use CNC programming, blueprint reading, and GD&T to ensure the accuracy and precision of the parts produced.

What skills are required to be a successful Croze Machine Operator?

Successful Croze Machine Operators typically have a strong understanding of CNC programming, blueprint reading, GD&T, sheet metal fabrication, and machine maintenance. They are also proficient in operating and troubleshooting croze machines, and they adhere to safety protocols and industry standards.

What are the career prospects for Croze Machine Operators?

Croze Machine Operators can advance their careers by developing specialized skills, such as welding, programming, or quality control. They may also move into supervisory or management roles, or become involved in research and development.

What is the work environment like for Croze Machine Operators?

Croze Machine Operators typically work in manufacturing facilities, where they operate machinery and interact with other team members. They may work in a variety of settings, including production lines, fabrication shops, and machine shops.

What are the benefits of being a Croze Machine Operator?

Croze Machine Operators can enjoy a number of benefits, including competitive salaries, opportunities for career advancement, and a sense of pride in their work. They also have the opportunity to work with cutting-edge technology and contribute to the production of high-quality products.