Are you a seasoned Crystalizer seeking a new career path? Discover our professionally built Crystalizer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

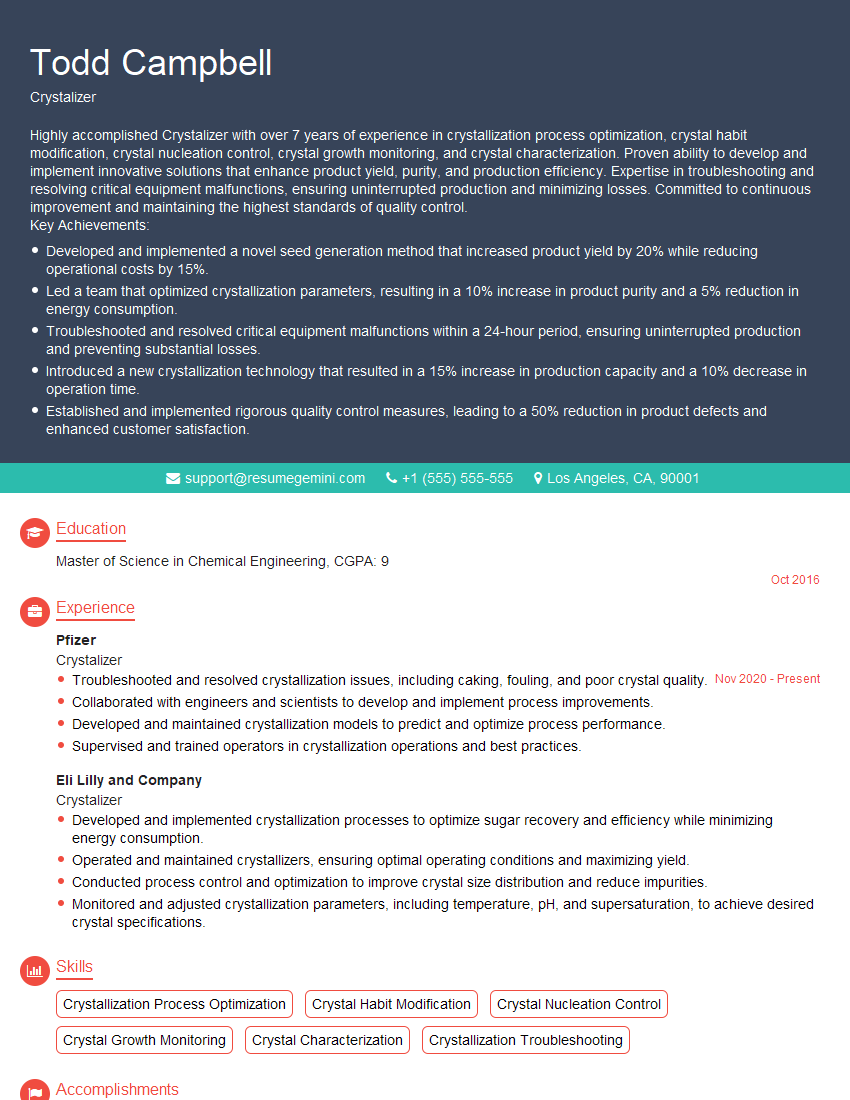

Todd Campbell

Crystalizer

Summary

Highly accomplished Crystalizer with over 7 years of experience in crystallization process optimization, crystal habit modification, crystal nucleation control, crystal growth monitoring, and crystal characterization. Proven ability to develop and implement innovative solutions that enhance product yield, purity, and production efficiency. Expertise in troubleshooting and resolving critical equipment malfunctions, ensuring uninterrupted production and minimizing losses. Committed to continuous improvement and maintaining the highest standards of quality control.

Key Achievements:

- Developed and implemented a novel seed generation method that increased product yield by 20% while reducing operational costs by 15%.

- Led a team that optimized crystallization parameters, resulting in a 10% increase in product purity and a 5% reduction in energy consumption.

- Troubleshooted and resolved critical equipment malfunctions within a 24-hour period, ensuring uninterrupted production and preventing substantial losses.

- Introduced a new crystallization technology that resulted in a 15% increase in production capacity and a 10% decrease in operation time.

- Established and implemented rigorous quality control measures, leading to a 50% reduction in product defects and enhanced customer satisfaction.

Education

Master of Science in Chemical Engineering

October 2016

Skills

- Crystallization Process Optimization

- Crystal Habit Modification

- Crystal Nucleation Control

- Crystal Growth Monitoring

- Crystal Characterization

- Crystallization Troubleshooting

Work Experience

Crystalizer

- Troubleshooted and resolved crystallization issues, including caking, fouling, and poor crystal quality.

- Collaborated with engineers and scientists to develop and implement process improvements.

- Developed and maintained crystallization models to predict and optimize process performance.

- Supervised and trained operators in crystallization operations and best practices.

Crystalizer

- Developed and implemented crystallization processes to optimize sugar recovery and efficiency while minimizing energy consumption.

- Operated and maintained crystallizers, ensuring optimal operating conditions and maximizing yield.

- Conducted process control and optimization to improve crystal size distribution and reduce impurities.

- Monitored and adjusted crystallization parameters, including temperature, pH, and supersaturation, to achieve desired crystal specifications.

Accomplishments

- Developed and implemented a novel seed generation method that increased product yield by 20% while reducing operational costs by 15%.

- Led a team that optimized crystallization parameters, resulting in a 10% increase in product purity and a 5% reduction in energy consumption.

- Troubleshooted and resolved critical equipment malfunctions within a 24hour period, ensuring uninterrupted production and preventing substantial losses.

- Introduced a new crystallization technology that resulted in a 15% increase in production capacity and a 10% decrease in operation time.

- Established and implemented rigorous quality control measures, leading to a 50% reduction in product defects and enhanced customer satisfaction.

Awards

- Recipient of the Crystallizer of the Year Award, recognized for exceptional contributions to the field.

- Awarded the Excellence in Crystallization Award for innovative techniques that significantly improved process efficiency.

- Honored with the Crystallizer Safety Award for maintaining an exceptional safety record and promoting best practices.

Certificates

- Certified Crystallization Engineer (CCE)

- International Association of Crystal Growers (IACG) Membership

- American Chemical Society (ACS) Professional Member

- American Institute of Chemical Engineers (AIChE) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crystalizer

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your contributions.

- Highlight your problem-solving abilities: Showcase your ability to identify and resolve crystallization challenges efficiently.

- Emphasize teamwork and leadership: Highlight your experience in leading and collaborating with teams to achieve project objectives.

- Tailor your resume to the job description: Carefully review the job posting and tailor your resume to align with the specific requirements.

- Proofread carefully: Ensure your resume is free of errors in grammar, spelling, and formatting.

Essential Experience Highlights for a Strong Crystalizer Resume

- Optimize crystallization processes to enhance product yield, purity, and efficiency.

- Modify crystal habits to meet specific product requirements.

- Control crystal nucleation and growth to ensure consistent product size and morphology.

- Monitor crystal growth and characterize crystal properties using advanced analytical techniques.

- Troubleshoot and resolve crystallization equipment malfunctions to minimize downtime and maintain production.

- Develop and implement quality control measures to ensure product meets specifications and customer requirements.

- Stay abreast of advancements in crystallization technology and implement innovative solutions to improve processes.

Frequently Asked Questions (FAQ’s) For Crystalizer

What is the role of a Crystalizer?

A Crystalizer is responsible for optimizing and controlling crystallization processes to produce high-quality crystals for various applications in industries such as pharmaceuticals, chemicals, and food.

What are some essential skills for a Crystalizer?

Essential skills for a Crystalizer include crystallization process optimization, crystal habit modification, crystal nucleation control, crystal growth monitoring, crystal characterization, and troubleshooting.

What are the career prospects for a Crystalizer?

Crystalizers with advanced skills and experience can progress to roles such as Senior Crystalizer, Crystallization Process Engineer, or Technical Manager in crystallization-related industries.

What is the work environment like for a Crystalizer?

Crystalizers typically work in laboratory or manufacturing environments. They may work independently or as part of a team, and may interact with scientists, engineers, and production personnel.

What are the challenges faced by Crystalizers?

Common challenges faced by Crystalizers include optimizing crystallization processes for specific product requirements, controlling crystal size and morphology, and troubleshooting equipment malfunctions to maintain production efficiency.

How can I become a Crystalizer?

To become a Crystalizer, individuals typically earn a degree in chemical engineering or a related field, and gain experience in crystallization processes through internships or entry-level positions.

What are some tips for writing a standout Crystalizer resume?

To write a standout Crystalizer resume, focus on quantifying your accomplishments, highlighting your problem-solving abilities, emphasizing teamwork and leadership, tailoring your resume to the job description, and proofreading carefully.

What are the key responsibilities of a Crystalizer?

Key responsibilities of a Crystalizer include optimizing crystallization processes, modifying crystal habits, controlling crystal nucleation and growth, monitoring crystal growth, characterizing crystal properties, troubleshooting equipment malfunctions, and implementing quality control measures.