Are you a seasoned Cuffing Machine Operator seeking a new career path? Discover our professionally built Cuffing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

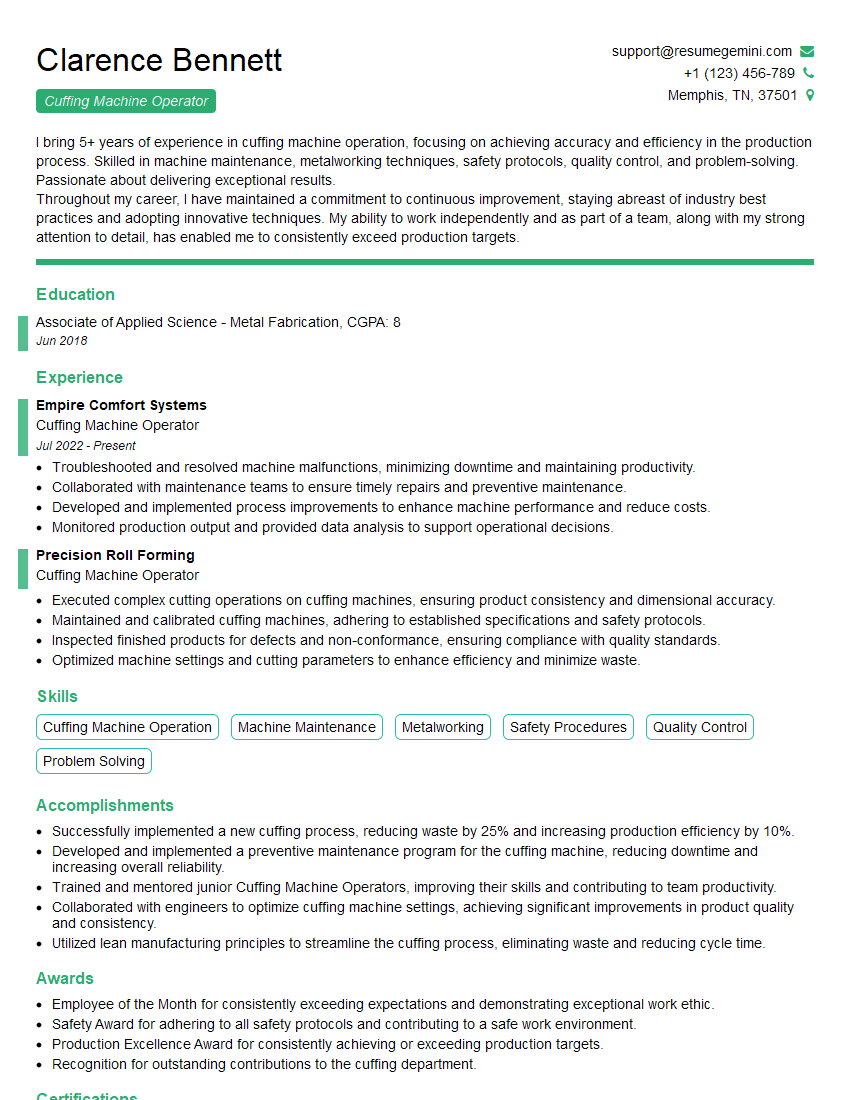

Clarence Bennett

Cuffing Machine Operator

Summary

I bring 5+ years of experience in cuffing machine operation, focusing on achieving accuracy and efficiency in the production process. Skilled in machine maintenance, metalworking techniques, safety protocols, quality control, and problem-solving. Passionate about delivering exceptional results.

Throughout my career, I have maintained a commitment to continuous improvement, staying abreast of industry best practices and adopting innovative techniques. My ability to work independently and as part of a team, along with my strong attention to detail, has enabled me to consistently exceed production targets.

Education

Associate of Applied Science – Metal Fabrication

June 2018

Skills

- Cuffing Machine Operation

- Machine Maintenance

- Metalworking

- Safety Procedures

- Quality Control

- Problem Solving

Work Experience

Cuffing Machine Operator

- Troubleshooted and resolved machine malfunctions, minimizing downtime and maintaining productivity.

- Collaborated with maintenance teams to ensure timely repairs and preventive maintenance.

- Developed and implemented process improvements to enhance machine performance and reduce costs.

- Monitored production output and provided data analysis to support operational decisions.

Cuffing Machine Operator

- Executed complex cutting operations on cuffing machines, ensuring product consistency and dimensional accuracy.

- Maintained and calibrated cuffing machines, adhering to established specifications and safety protocols.

- Inspected finished products for defects and non-conformance, ensuring compliance with quality standards.

- Optimized machine settings and cutting parameters to enhance efficiency and minimize waste.

Accomplishments

- Successfully implemented a new cuffing process, reducing waste by 25% and increasing production efficiency by 10%.

- Developed and implemented a preventive maintenance program for the cuffing machine, reducing downtime and increasing overall reliability.

- Trained and mentored junior Cuffing Machine Operators, improving their skills and contributing to team productivity.

- Collaborated with engineers to optimize cuffing machine settings, achieving significant improvements in product quality and consistency.

- Utilized lean manufacturing principles to streamline the cuffing process, eliminating waste and reducing cycle time.

Awards

- Employee of the Month for consistently exceeding expectations and demonstrating exceptional work ethic.

- Safety Award for adhering to all safety protocols and contributing to a safe work environment.

- Production Excellence Award for consistently achieving or exceeding production targets.

- Recognition for outstanding contributions to the cuffing department.

Certificates

- Cuffing Machine Operator Certification

- Occupational Safety and Health Administration (OSHA) Certification

- International Standards Organization (ISO) 9001 Certification

- National Institute for Metalworking Skills (NIMS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cuffing Machine Operator

- Highlight your relevant skills and experience: Emphasize your expertise in cuffing machine operation, maintenance, and metalworking techniques. Quantify your accomplishments with specific metrics whenever possible.

- Tailor your resume to the job description: Carefully review the job requirements and align your resume to demonstrate how your skills and experience match the needs of the employer.

- Showcase your attention to detail: Proofread your resume thoroughly for any errors in grammar, spelling, or formatting. This demonstrates your professionalism and attention to accuracy.

- Use industry-specific keywords: Incorporate relevant terms such as ‘cuffing machine,’ ‘metal fabrication,’ and ‘quality control’ to make your resume more easily discoverable by potential employers.

Essential Experience Highlights for a Strong Cuffing Machine Operator Resume

- Operate and maintain a cuffing machine to form sheet metal components with precision and efficiency.

- Set up and adjust machine parameters, including tooling, feed rates, and speed, to optimize production.

- Monitor machine performance, identify potential issues, and perform routine maintenance to ensure smooth operation.

- Conduct quality control checks on finished parts, adhering to established standards and specifications.

- Troubleshoot and resolve operational problems promptly, minimizing downtime and maintaining productivity.

- Maintain a clean and organized work area, ensuring compliance with safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Cuffing Machine Operator

What is the primary function of a Cuffing Machine Operator?

Cuffing Machine Operators are responsible for operating and maintaining cuffing machines, which are used to form and shape sheet metal components. They set up and adjust machine parameters, monitor performance, conduct quality control checks, troubleshoot issues, and ensure a safe and efficient work environment.

What are the essential skills required to be an effective Cuffing Machine Operator?

Effective Cuffing Machine Operators possess strong mechanical skills, including the ability to operate and maintain cuffing machines. They are proficient in metalworking techniques, safety protocols, quality control procedures, and problem-solving. Good communication and teamwork abilities are also valuable.

What are the career prospects for a Cuffing Machine Operator?

Cuffing Machine Operators can advance their careers by gaining experience and developing additional skills. They may become supervisors or trainers, or move into related roles in metal fabrication or manufacturing. With specialized training, they can also pursue opportunities in quality control or engineering.

What is the average salary range for a Cuffing Machine Operator?

The average salary range for Cuffing Machine Operators varies depending on factors such as experience, location, and company size. According to Indeed, the national average salary for a Cuffing Machine Operator is approximately $20 per hour.

What are the key qualities of a successful Cuffing Machine Operator?

Successful Cuffing Machine Operators are detail-oriented, safety-conscious, and committed to producing high-quality work. They are able to work independently and as part of a team, and are always looking for ways to improve their skills and knowledge.

What are some of the challenges faced by Cuffing Machine Operators?

Cuffing Machine Operators may face challenges such as working in a noisy and potentially hazardous environment, meeting tight production deadlines, and ensuring the accuracy and quality of their work. They may also need to stay updated on new technologies and industry best practices.