Are you a seasoned Cut-Off Machine Operator seeking a new career path? Discover our professionally built Cut-Off Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

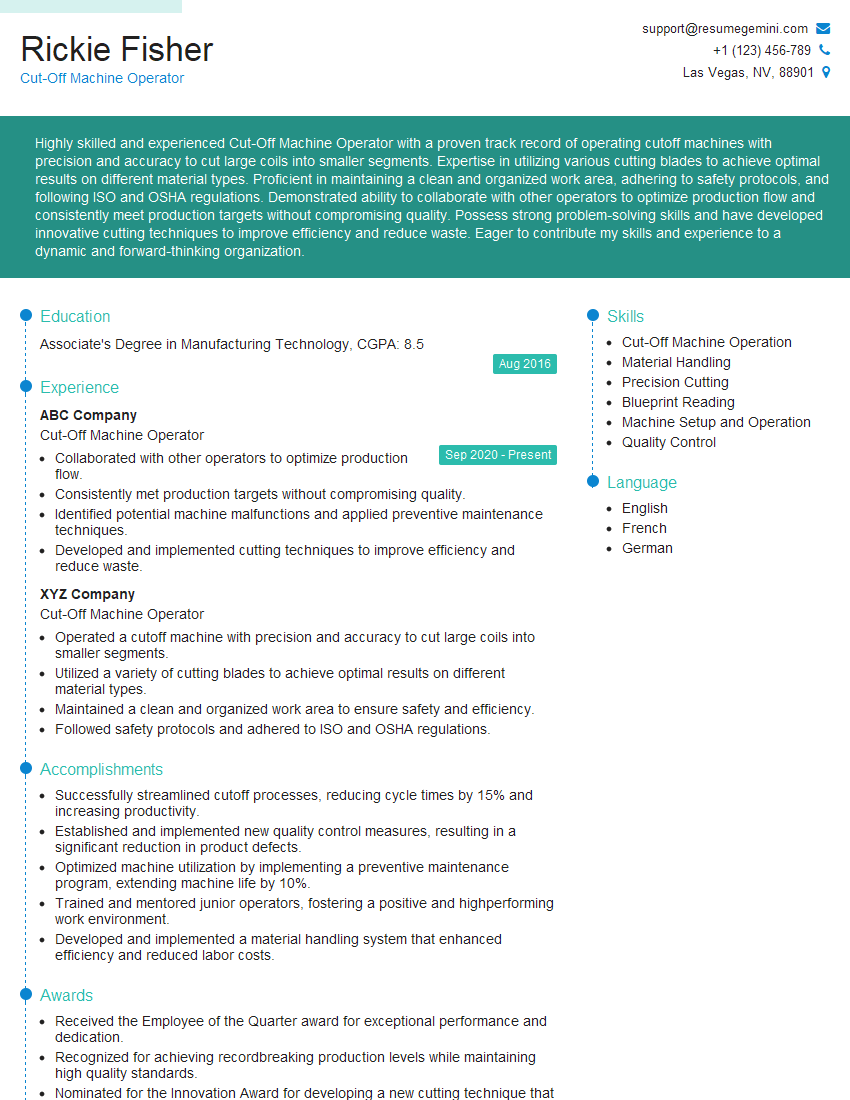

Rickie Fisher

Cut-Off Machine Operator

Summary

Highly skilled and experienced Cut-Off Machine Operator with a proven track record of operating cutoff machines with precision and accuracy to cut large coils into smaller segments. Expertise in utilizing various cutting blades to achieve optimal results on different material types. Proficient in maintaining a clean and organized work area, adhering to safety protocols, and following ISO and OSHA regulations. Demonstrated ability to collaborate with other operators to optimize production flow and consistently meet production targets without compromising quality. Possess strong problem-solving skills and have developed innovative cutting techniques to improve efficiency and reduce waste. Eager to contribute my skills and experience to a dynamic and forward-thinking organization.

Education

Associate’s Degree in Manufacturing Technology

August 2016

Skills

- Cut-Off Machine Operation

- Material Handling

- Precision Cutting

- Blueprint Reading

- Machine Setup and Operation

- Quality Control

Work Experience

Cut-Off Machine Operator

- Collaborated with other operators to optimize production flow.

- Consistently met production targets without compromising quality.

- Identified potential machine malfunctions and applied preventive maintenance techniques.

- Developed and implemented cutting techniques to improve efficiency and reduce waste.

Cut-Off Machine Operator

- Operated a cutoff machine with precision and accuracy to cut large coils into smaller segments.

- Utilized a variety of cutting blades to achieve optimal results on different material types.

- Maintained a clean and organized work area to ensure safety and efficiency.

- Followed safety protocols and adhered to ISO and OSHA regulations.

Accomplishments

- Successfully streamlined cutoff processes, reducing cycle times by 15% and increasing productivity.

- Established and implemented new quality control measures, resulting in a significant reduction in product defects.

- Optimized machine utilization by implementing a preventive maintenance program, extending machine life by 10%.

- Trained and mentored junior operators, fostering a positive and highperforming work environment.

- Developed and implemented a material handling system that enhanced efficiency and reduced labor costs.

Awards

- Received the Employee of the Quarter award for exceptional performance and dedication.

- Recognized for achieving recordbreaking production levels while maintaining high quality standards.

- Nominated for the Innovation Award for developing a new cutting technique that significantly improved cut efficiency.

Certificates

- Certified Cut-Off Machine Operator (CCMO)

- OSHA 30-Hour Safety Training

- ISO 9001:2015 Quality Management System

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cut-Off Machine Operator

- Highlight your experience and skills in operating cutoff machines, including the types of materials you have worked with and the accuracy and precision you have achieved.

- Showcase your knowledge of safety protocols and regulations, such as ISO and OSHA, and emphasize your commitment to maintaining a safe work environment.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your productivity and efficiency.

- Include any additional skills or experience that are relevant to the role, such as blueprint reading, machine setup and operation, or quality control.

- Proofread your resume carefully for any errors in grammar or spelling, as these can detract from your professionalism.

Essential Experience Highlights for a Strong Cut-Off Machine Operator Resume

- Operated a cutoff machine with precision and accuracy to cut large coils into smaller segments.

- Utilized a variety of cutting blades to achieve optimal results on different material types.

- Maintained a clean and organized work area to ensure safety and efficiency.

- Followed safety protocols and adhered to ISO and OSHA regulations.

- Collaborated with other operators to optimize production flow.

- Consistently met production targets without compromising quality.

- Identified potential machine malfunctions and applied preventive maintenance techniques.

Frequently Asked Questions (FAQ’s) For Cut-Off Machine Operator

What is the primary responsibility of a Cut-Off Machine Operator?

The primary responsibility of a Cut-Off Machine Operator is to operate a cutoff machine to cut large coils into smaller segments, ensuring precision and accuracy while adhering to safety protocols and maintaining a clean and organized work area.

What skills are essential for a Cut-Off Machine Operator?

Essential skills for a Cut-Off Machine Operator include proficiency in operating cutoff machines, understanding of different material types and cutting techniques, commitment to safety and adherence to regulations, and the ability to maintain a clean and organized work area.

What are the career prospects for a Cut-Off Machine Operator?

Cut-Off Machine Operators can advance to supervisory roles, such as Production Supervisor or Manufacturing Manager, with experience and additional training. Some may also pursue specialization in operating specific types of cutoff machines or working with particular materials.

What is the average salary for a Cut-Off Machine Operator?

The average salary for a Cut-Off Machine Operator varies depending on factors such as experience, location, and industry. According to Salary.com, the average annual salary for Cut-Off Machine Operators in the United States is around $45,000.

What are the working conditions like for a Cut-Off Machine Operator?

Cut-Off Machine Operators typically work in manufacturing or industrial settings, operating cutoff machines in a production environment. The work can be physically demanding, involving repetitive motions and handling heavy materials. However, employers are increasingly implementing ergonomic practices and safety measures to ensure the well-being of their employees.

What are the educational requirements for a Cut-Off Machine Operator?

While formal education requirements may vary, many Cut-Off Machine Operators hold a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

What is the job outlook for Cut-Off Machine Operators?

The job outlook for Cut-Off Machine Operators is expected to be stable in the coming years. The demand for skilled manufacturing workers, including those operating specialized machinery, is projected to remain steady due to ongoing industrial production and the need for efficient and precise cutting operations in various industries.