Are you a seasoned Cutter Helper seeking a new career path? Discover our professionally built Cutter Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

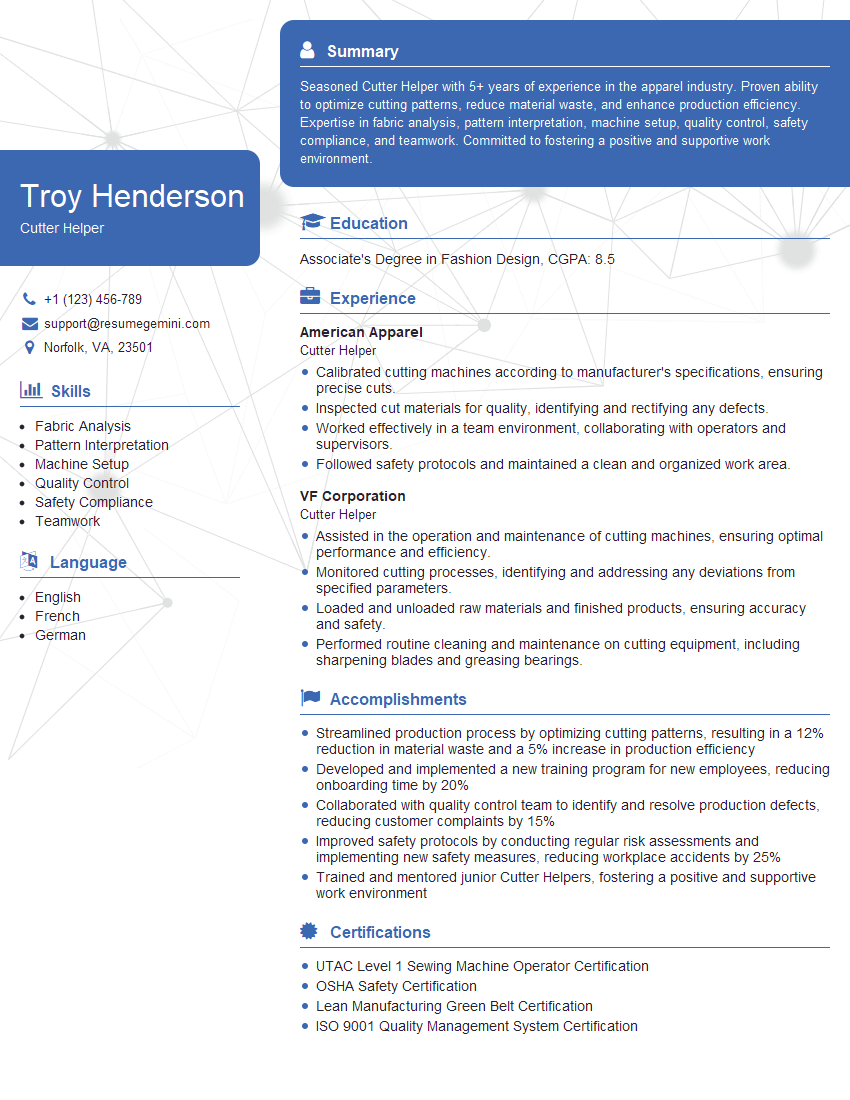

Troy Henderson

Cutter Helper

Summary

Seasoned Cutter Helper with 5+ years of experience in the apparel industry. Proven ability to optimize cutting patterns, reduce material waste, and enhance production efficiency. Expertise in fabric analysis, pattern interpretation, machine setup, quality control, safety compliance, and teamwork. Committed to fostering a positive and supportive work environment.

Education

Associate’s Degree in Fashion Design

March 2015

Skills

- Fabric Analysis

- Pattern Interpretation

- Machine Setup

- Quality Control

- Safety Compliance

- Teamwork

Work Experience

Cutter Helper

- Calibrated cutting machines according to manufacturer’s specifications, ensuring precise cuts.

- Inspected cut materials for quality, identifying and rectifying any defects.

- Worked effectively in a team environment, collaborating with operators and supervisors.

- Followed safety protocols and maintained a clean and organized work area.

Cutter Helper

- Assisted in the operation and maintenance of cutting machines, ensuring optimal performance and efficiency.

- Monitored cutting processes, identifying and addressing any deviations from specified parameters.

- Loaded and unloaded raw materials and finished products, ensuring accuracy and safety.

- Performed routine cleaning and maintenance on cutting equipment, including sharpening blades and greasing bearings.

Accomplishments

- Streamlined production process by optimizing cutting patterns, resulting in a 12% reduction in material waste and a 5% increase in production efficiency

- Developed and implemented a new training program for new employees, reducing onboarding time by 20%

- Collaborated with quality control team to identify and resolve production defects, reducing customer complaints by 15%

- Improved safety protocols by conducting regular risk assessments and implementing new safety measures, reducing workplace accidents by 25%

- Trained and mentored junior Cutter Helpers, fostering a positive and supportive work environment

Certificates

- UTAC Level 1 Sewing Machine Operator Certification

- OSHA Safety Certification

- Lean Manufacturing Green Belt Certification

- ISO 9001 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutter Helper

- Highlight your technical skills in fabric analysis, pattern interpretation, and machine setup.

- Quantify your accomplishments with specific metrics to demonstrate your impact on the organization.

- Showcase your commitment to safety and quality by emphasizing your adherence to safety protocols and quality control measures.

- Emphasize your ability to work effectively in a team environment and contribute to a positive work culture.

- Tailor your resume to each job application, highlighting the skills and experiences that are most relevant to the specific role.

Essential Experience Highlights for a Strong Cutter Helper Resume

- Streamlined production processes by optimizing cutting patterns, resulting in reduced material waste and increased production efficiency

- Developed and implemented a training program for new employees, reducing onboarding time

- Collaborated with the quality control team to identify and resolve production defects, minimizing customer complaints

- Improved safety protocols by conducting risk assessments and implementing new safety measures, reducing workplace accidents

- Trained and mentored junior Cutter Helpers, creating a positive work environment

Frequently Asked Questions (FAQ’s) For Cutter Helper

What are the primary responsibilities of a Cutter Helper?

Cutter Helpers assist in the cutting and preparation of fabrics and materials used in garment production. They may be responsible for fabric analysis, pattern interpretation, machine setup and operation, quality control, and ensuring safety compliance.

What skills are required to be a successful Cutter Helper?

Successful Cutter Helpers typically possess skills in fabric analysis, pattern interpretation, machine setup and operation, quality control, safety compliance, and teamwork.

What is the career path for a Cutter Helper?

With experience and additional training, Cutter Helpers can advance to roles such as Cutter, Pattern Maker, or Production Supervisor.

What is the average salary for a Cutter Helper?

According to Indeed, the average salary for a Cutter Helper in the United States is around \$16 per hour.

What are the job outlook prospects for Cutter Helpers?

The job outlook for Cutter Helpers is expected to be stable in the coming years, with a projected 2% growth rate from 2021 to 2031.

What are some tips for writing a standout Cutter Helper resume?

Highlight your technical skills, quantify your accomplishments, showcase your commitment to safety and quality, emphasize your teamwork abilities, and tailor your resume to each job application.

What are some common interview questions for Cutter Helpers?

Common interview questions for Cutter Helpers may include questions about your experience in fabric analysis, pattern interpretation, machine setup and operation, quality control, safety compliance, and teamwork.

What is the work environment like for a Cutter Helper?

Cutter Helpers typically work in a fast-paced manufacturing environment, often standing for long periods and operating machinery. They may work with sharp tools and materials, so safety precautions are essential.