Are you a seasoned Cutter Off seeking a new career path? Discover our professionally built Cutter Off Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

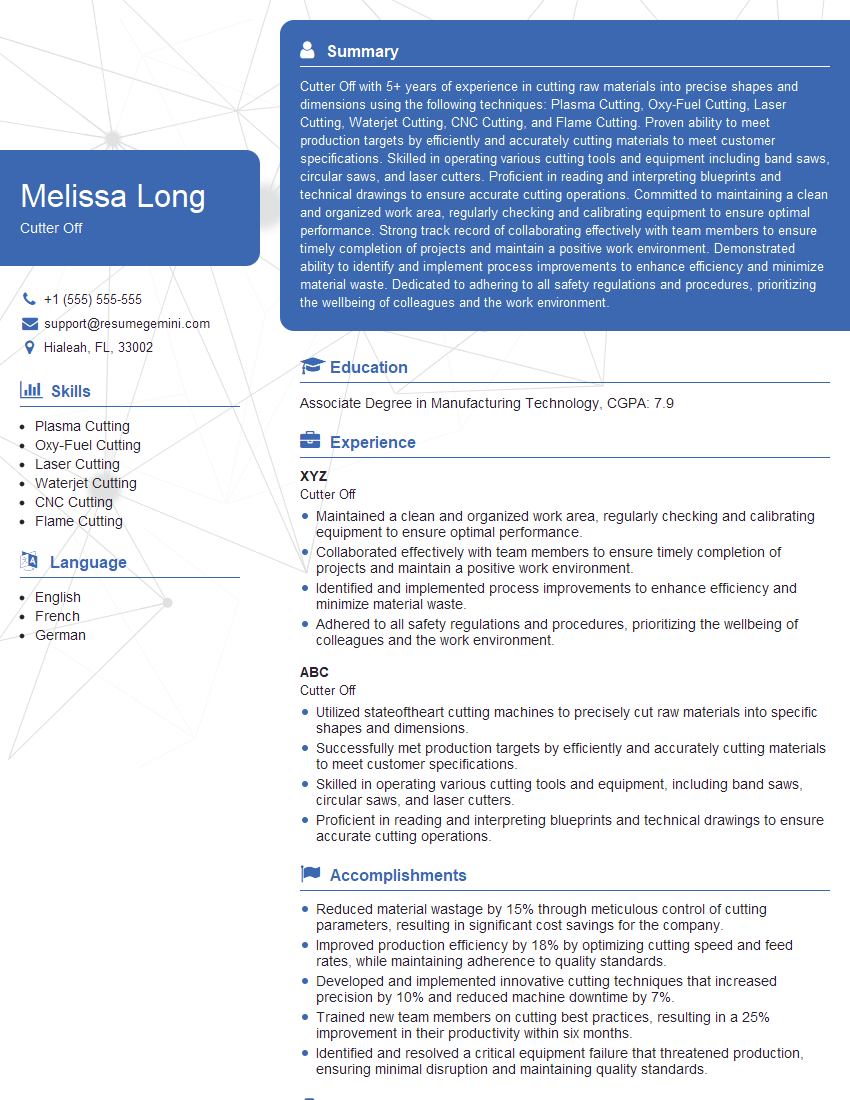

Melissa Long

Cutter Off

Summary

Cutter Off with 5+ years of experience in cutting raw materials into precise shapes and dimensions using the following techniques: Plasma Cutting, Oxy-Fuel Cutting, Laser Cutting, Waterjet Cutting, CNC Cutting, and Flame Cutting. Proven ability to meet production targets by efficiently and accurately cutting materials to meet customer specifications. Skilled in operating various cutting tools and equipment including band saws, circular saws, and laser cutters. Proficient in reading and interpreting blueprints and technical drawings to ensure accurate cutting operations. Committed to maintaining a clean and organized work area, regularly checking and calibrating equipment to ensure optimal performance. Strong track record of collaborating effectively with team members to ensure timely completion of projects and maintain a positive work environment. Demonstrated ability to identify and implement process improvements to enhance efficiency and minimize material waste. Dedicated to adhering to all safety regulations and procedures, prioritizing the wellbeing of colleagues and the work environment.

Education

Associate Degree in Manufacturing Technology

July 2019

Skills

- Plasma Cutting

- Oxy-Fuel Cutting

- Laser Cutting

- Waterjet Cutting

- CNC Cutting

- Flame Cutting

Work Experience

Cutter Off

- Maintained a clean and organized work area, regularly checking and calibrating equipment to ensure optimal performance.

- Collaborated effectively with team members to ensure timely completion of projects and maintain a positive work environment.

- Identified and implemented process improvements to enhance efficiency and minimize material waste.

- Adhered to all safety regulations and procedures, prioritizing the wellbeing of colleagues and the work environment.

Cutter Off

- Utilized stateoftheart cutting machines to precisely cut raw materials into specific shapes and dimensions.

- Successfully met production targets by efficiently and accurately cutting materials to meet customer specifications.

- Skilled in operating various cutting tools and equipment, including band saws, circular saws, and laser cutters.

- Proficient in reading and interpreting blueprints and technical drawings to ensure accurate cutting operations.

Accomplishments

- Reduced material wastage by 15% through meticulous control of cutting parameters, resulting in significant cost savings for the company.

- Improved production efficiency by 18% by optimizing cutting speed and feed rates, while maintaining adherence to quality standards.

- Developed and implemented innovative cutting techniques that increased precision by 10% and reduced machine downtime by 7%.

- Trained new team members on cutting best practices, resulting in a 25% improvement in their productivity within six months.

- Identified and resolved a critical equipment failure that threatened production, ensuring minimal disruption and maintaining quality standards.

Awards

- Won the Excellence in Cutting Operations award for consistently exceeding production targets with exceptional precision and accuracy.

- Received the Safety Champion award for demonstrating exemplary safety practices and contributing to a hazardfree work environment.

- Recognized for exceptional contributions to the team, including mentorship and collaboration on critical cutting projects.

- Received the Employee of the Month award for outstanding performance, teamwork, and commitment to the company.

Certificates

- Certified Plasma Cutter

- Certified Oxy-Fuel Cutter

- Certified Laser Cutter

- Certified Waterjet Cutter

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutter Off

- Highlight your experience and skills in operating various cutting machines and techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure there are no errors.

Essential Experience Highlights for a Strong Cutter Off Resume

- Utilized state-of-the-art cutting machines to precisely cut raw materials into specific shapes and dimensions.

- Successfully met production targets by efficiently and accurately cutting materials to meet customer specifications.

- Skilled in operating various cutting tools and equipment, including band saws, circular saws, and laser cutters.

- Proficient in reading and interpreting blueprints and technical drawings to ensure accurate cutting operations.

- Maintained a clean and organized work area, regularly checking and calibrating equipment to ensure optimal performance.

- Collaborated effectively with team members to ensure timely completion of projects and maintain a positive work environment.

- Identified and implemented process improvements to enhance efficiency and minimize material waste.

Frequently Asked Questions (FAQ’s) For Cutter Off

What are the key qualities and skills required to be a successful Cutter Off?

Attention to detail, strong hand-eye coordination, ability to follow instructions, and experience operating cutting machines.

What are the different types of cutting techniques used by Cutter Offs?

Plasma Cutting, Oxy-Fuel Cutting, Laser Cutting, Waterjet Cutting, CNC Cutting, and Flame Cutting.

What are the safety precautions that Cutter Offs must follow?

Wearing appropriate safety gear, following proper operating procedures, and maintaining a clean and organized work area.

What are the career advancement opportunities for Cutter Offs?

Quality Control Inspector or Supervisor, CNC Operator, or Production Manager.

What are the common challenges faced by Cutter Offs?

Meeting tight deadlines, ensuring precision and accuracy, and handling hazardous materials.

What is the work environment like for Cutter Offs?

Typically work in a manufacturing or fabrication environment, often in a team setting.

What are the physical demands of being a Cutter Off?

Requires standing for long periods, lifting heavy materials, and using repetitive hand motions.

What is the job outlook for Cutter Offs?

Expected to grow faster than average in the coming years due to increasing demand for skilled manufacturing workers.