Are you a seasoned Cutter Operator seeking a new career path? Discover our professionally built Cutter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

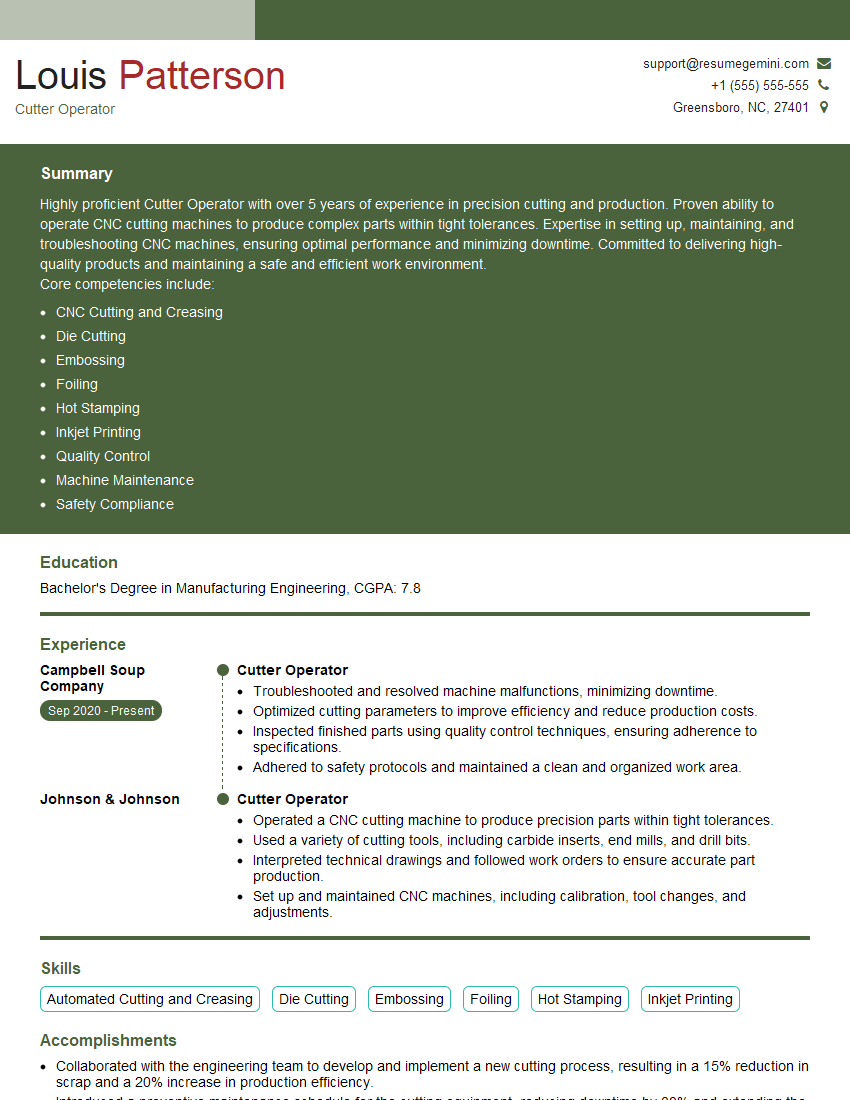

Louis Patterson

Cutter Operator

Summary

Highly proficient Cutter Operator with over 5 years of experience in precision cutting and production. Proven ability to operate CNC cutting machines to produce complex parts within tight tolerances. Expertise in setting up, maintaining, and troubleshooting CNC machines, ensuring optimal performance and minimizing downtime. Committed to delivering high-quality products and maintaining a safe and efficient work environment.

Core competencies include:

- CNC Cutting and Creasing

- Die Cutting

- Embossing

- Foiling

- Hot Stamping

- Inkjet Printing

- Quality Control

- Machine Maintenance

- Safety Compliance

Education

Bachelor’s Degree in Manufacturing Engineering

August 2016

Skills

- Automated Cutting and Creasing

- Die Cutting

- Embossing

- Foiling

- Hot Stamping

- Inkjet Printing

Work Experience

Cutter Operator

- Troubleshooted and resolved machine malfunctions, minimizing downtime.

- Optimized cutting parameters to improve efficiency and reduce production costs.

- Inspected finished parts using quality control techniques, ensuring adherence to specifications.

- Adhered to safety protocols and maintained a clean and organized work area.

Cutter Operator

- Operated a CNC cutting machine to produce precision parts within tight tolerances.

- Used a variety of cutting tools, including carbide inserts, end mills, and drill bits.

- Interpreted technical drawings and followed work orders to ensure accurate part production.

- Set up and maintained CNC machines, including calibration, tool changes, and adjustments.

Accomplishments

- Collaborated with the engineering team to develop and implement a new cutting process, resulting in a 15% reduction in scrap and a 20% increase in production efficiency.

- Introduced a preventive maintenance schedule for the cutting equipment, reducing downtime by 30% and extending the lifespan of the machines.

- Utilized lean manufacturing principles to streamline the cutting process, improving lead times by 25%.

- Developed a training program for new cutters, resulting in a 30% increase in productivity within six months.

- Conducted regular quality inspections, ensuring that all products met the highest standards and customer specifications.

Awards

- Received the Employee of the Month award for consistently exceeding production targets and maintaining exceptional quality standards.

- Received the Safety Champion award for consistently adhering to all safety protocols and promoting a positive safety culture.

Certificates

- OSHA 30-Hour Safety Certification

- Six Sigma Green Belt Certification

- Certified Production Technician (CPT)

- National Institute for Metalworking Skills (NIMS) Credential

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutter Operator

- Highlight your experience and skills in CNC cutting and production.

- Showcase your knowledge of different cutting tools and techniques.

- Emphasize your ability to set up, maintain, and troubleshoot CNC machines.

- Demonstrate your commitment to quality control and safety in the workplace.

- Provide specific examples of projects or accomplishments that showcase your abilities.

Essential Experience Highlights for a Strong Cutter Operator Resume

- Operate CNC cutting machines to produce precise parts according to specifications and work orders

- Interpret technical drawings and convert them into machine programs using CAM software

- Set up and maintain CNC machines, including calibration, tool changes, and adjustments

- Troubleshoot and resolve machine malfunctions, minimizing downtime and maximizing productivity

- Inspect finished parts using quality control techniques, ensuring adherence to specifications

- Adhere to safety protocols and maintain a clean, organized work area

- Collaborate with other team members to ensure smooth production flow and meet deadlines

Frequently Asked Questions (FAQ’s) For Cutter Operator

What are the key skills required to be a successful Cutter Operator?

Key skills include experience in CNC cutting and production, knowledge of different cutting tools and techniques, ability to set up, maintain, and troubleshoot CNC machines, commitment to quality control and safety, and strong attention to detail.

What are the career advancement opportunities for a Cutter Operator?

With experience and additional training, Cutter Operators can advance to positions such as CNC Programmer, Production Supervisor, or Quality Control Manager.

What are the different industries that employ Cutter Operators?

Cutter Operators are employed in various industries, including manufacturing, packaging, printing, and automotive.

What is the average salary for a Cutter Operator?

The average salary for a Cutter Operator varies depending on experience, location, and industry. According to Salary.com, the average salary for a Cutter Operator in the United States is around $25,000 to $45,000 per year.

What are the working conditions like for a Cutter Operator?

Cutter Operators typically work in manufacturing environments, which can be noisy and have potential hazards. They may be required to work in shifts or overtime to meet production demands.

What is the job outlook for Cutter Operators?

The job outlook for Cutter Operators is expected to be stable in the coming years. The increasing use of CNC machines in manufacturing is driving the demand for skilled operators.