Are you a seasoned Cutter seeking a new career path? Discover our professionally built Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

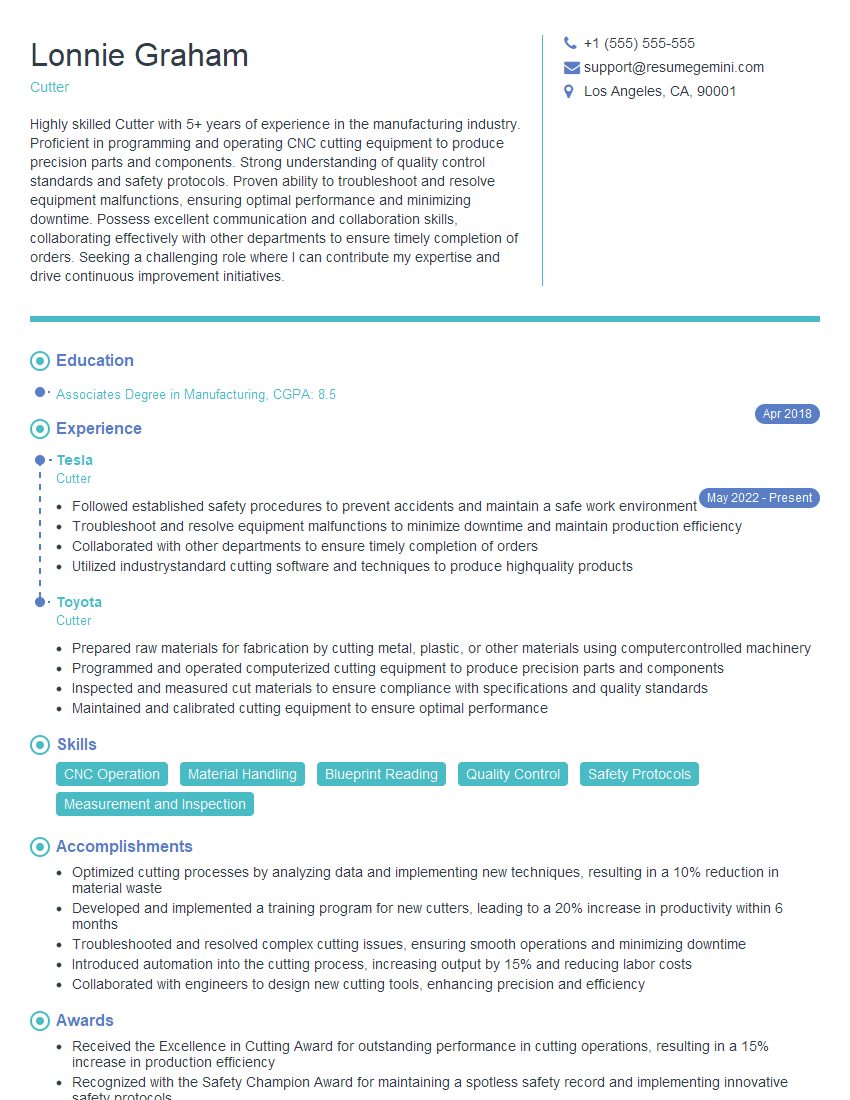

Lonnie Graham

Cutter

Summary

Highly skilled Cutter with 5+ years of experience in the manufacturing industry. Proficient in programming and operating CNC cutting equipment to produce precision parts and components. Strong understanding of quality control standards and safety protocols. Proven ability to troubleshoot and resolve equipment malfunctions, ensuring optimal performance and minimizing downtime. Possess excellent communication and collaboration skills, collaborating effectively with other departments to ensure timely completion of orders. Seeking a challenging role where I can contribute my expertise and drive continuous improvement initiatives.

Education

Associates Degree in Manufacturing

April 2018

Skills

- CNC Operation

- Material Handling

- Blueprint Reading

- Quality Control

- Safety Protocols

- Measurement and Inspection

Work Experience

Cutter

- Followed established safety procedures to prevent accidents and maintain a safe work environment

- Troubleshoot and resolve equipment malfunctions to minimize downtime and maintain production efficiency

- Collaborated with other departments to ensure timely completion of orders

- Utilized industrystandard cutting software and techniques to produce highquality products

Cutter

- Prepared raw materials for fabrication by cutting metal, plastic, or other materials using computercontrolled machinery

- Programmed and operated computerized cutting equipment to produce precision parts and components

- Inspected and measured cut materials to ensure compliance with specifications and quality standards

- Maintained and calibrated cutting equipment to ensure optimal performance

Accomplishments

- Optimized cutting processes by analyzing data and implementing new techniques, resulting in a 10% reduction in material waste

- Developed and implemented a training program for new cutters, leading to a 20% increase in productivity within 6 months

- Troubleshooted and resolved complex cutting issues, ensuring smooth operations and minimizing downtime

- Introduced automation into the cutting process, increasing output by 15% and reducing labor costs

- Collaborated with engineers to design new cutting tools, enhancing precision and efficiency

Awards

- Received the Excellence in Cutting Award for outstanding performance in cutting operations, resulting in a 15% increase in production efficiency

- Recognized with the Safety Champion Award for maintaining a spotless safety record and implementing innovative safety protocols

- Named Employee of the Month for consistently exceeding cutting quality standards and contributing to team success

Certificates

- NCCER Craft Training

- OSHA Safety Certification

- ISO 9001 Certification

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutter

- Highlight your technical skills and experience in CNC cutting operations.

- Showcase your understanding of quality control processes and safety protocols.

- Quantify your accomplishments and provide specific examples of your contributions.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Cutter Resume

- Prepared raw materials for fabrication by cutting metal, plastic, or other materials using computercontrolled machinery.

- Programmed and operated computerized cutting equipment to produce precision parts and components.

- Inspected and measured cut materials to ensure compliance with specifications and quality standards.

- Maintained and calibrated cutting equipment to ensure optimal performance.

- Followed established safety procedures to prevent accidents and maintain a safe work environment.

- Troubleshoot and resolve equipment malfunctions to minimize downtime and maintain production efficiency.

- Collaborated with other departments to ensure timely completion of orders.

- Utilized industry-standard cutting software and techniques to produce high-quality products.

Frequently Asked Questions (FAQ’s) For Cutter

What are the key skills required for a Cutter?

CNC Operation, Material Handling, Blueprint Reading, Quality Control, Safety Protocols, Measurement, and Inspection.

What are the educational qualifications required to become a Cutter?

An Associates Degree in Manufacturing, or a related field, is typically required.

What are the career prospects for Cutters?

With experience, Cutters can advance to supervisory roles or specialize in specific areas of cutting, such as laser cutting or waterjet cutting.

What is the work environment for Cutters like?

Cutters typically work in manufacturing facilities, operating CNC cutting machines. The work can be physically demanding and may involve working with hazardous materials.

What are the safety protocols that Cutters must follow?

Cutters must follow established safety procedures to prevent accidents and maintain a safe work environment. This includes wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of the hazards associated with cutting operations.

What are the challenges that Cutters face?

Cutters face challenges such as working with tight tolerances, meeting production deadlines, and ensuring the quality of cut materials. They must also stay up-to-date on the latest cutting technologies and techniques.