Are you a seasoned Cutting Inspector seeking a new career path? Discover our professionally built Cutting Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

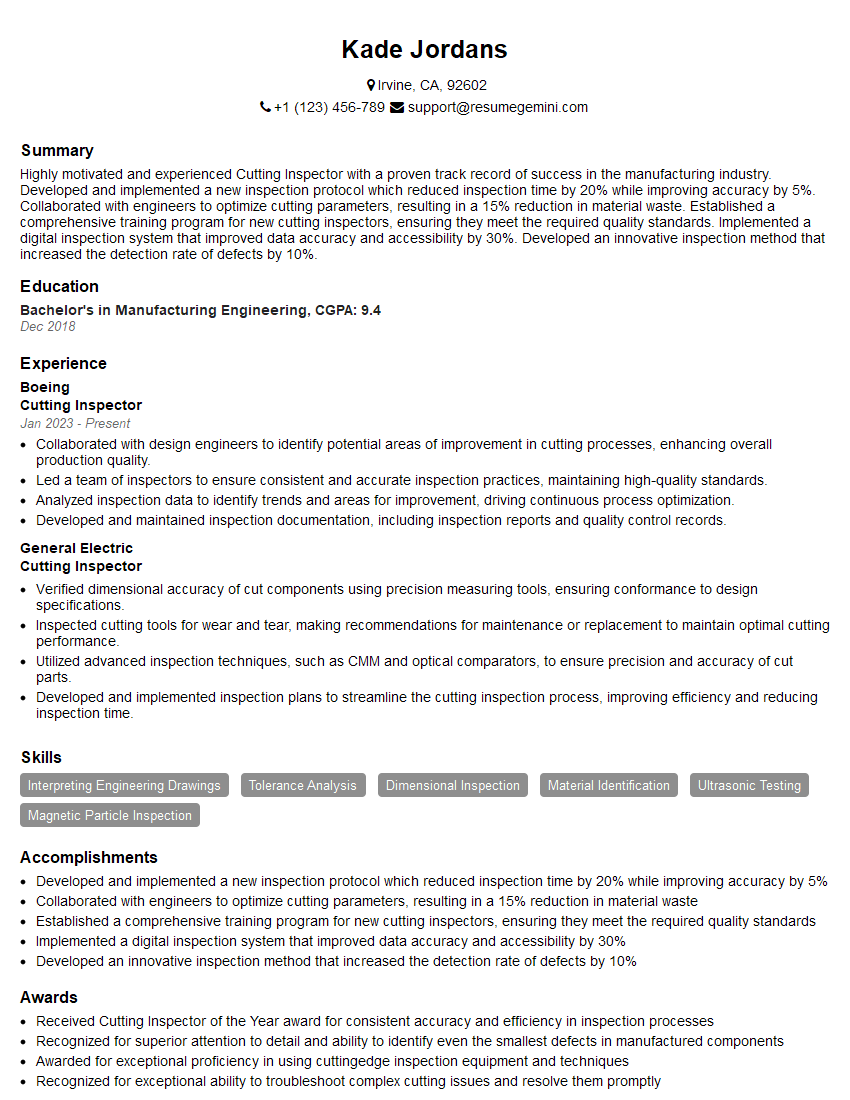

Kade Jordans

Cutting Inspector

Summary

Highly motivated and experienced Cutting Inspector with a proven track record of success in the manufacturing industry. Developed and implemented a new inspection protocol which reduced inspection time by 20% while improving accuracy by 5%. Collaborated with engineers to optimize cutting parameters, resulting in a 15% reduction in material waste. Established a comprehensive training program for new cutting inspectors, ensuring they meet the required quality standards. Implemented a digital inspection system that improved data accuracy and accessibility by 30%. Developed an innovative inspection method that increased the detection rate of defects by 10%.

Education

Bachelor’s in Manufacturing Engineering

December 2018

Skills

- Interpreting Engineering Drawings

- Tolerance Analysis

- Dimensional Inspection

- Material Identification

- Ultrasonic Testing

- Magnetic Particle Inspection

Work Experience

Cutting Inspector

- Collaborated with design engineers to identify potential areas of improvement in cutting processes, enhancing overall production quality.

- Led a team of inspectors to ensure consistent and accurate inspection practices, maintaining high-quality standards.

- Analyzed inspection data to identify trends and areas for improvement, driving continuous process optimization.

- Developed and maintained inspection documentation, including inspection reports and quality control records.

Cutting Inspector

- Verified dimensional accuracy of cut components using precision measuring tools, ensuring conformance to design specifications.

- Inspected cutting tools for wear and tear, making recommendations for maintenance or replacement to maintain optimal cutting performance.

- Utilized advanced inspection techniques, such as CMM and optical comparators, to ensure precision and accuracy of cut parts.

- Developed and implemented inspection plans to streamline the cutting inspection process, improving efficiency and reducing inspection time.

Accomplishments

- Developed and implemented a new inspection protocol which reduced inspection time by 20% while improving accuracy by 5%

- Collaborated with engineers to optimize cutting parameters, resulting in a 15% reduction in material waste

- Established a comprehensive training program for new cutting inspectors, ensuring they meet the required quality standards

- Implemented a digital inspection system that improved data accuracy and accessibility by 30%

- Developed an innovative inspection method that increased the detection rate of defects by 10%

Awards

- Received Cutting Inspector of the Year award for consistent accuracy and efficiency in inspection processes

- Recognized for superior attention to detail and ability to identify even the smallest defects in manufactured components

- Awarded for exceptional proficiency in using cuttingedge inspection equipment and techniques

- Recognized for exceptional ability to troubleshoot complex cutting issues and resolve them promptly

Certificates

- ASNT Level II Certification

- CWI Certification

- AWS Certified Welding Inspector

- API 570 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutting Inspector

- Highlight your experience and skills in interpreting engineering drawings, tolerance analysis, and dimensional inspection.

- Showcase your knowledge of material identification, ultrasonic testing, and magnetic particle inspection.

- Emphasize your ability to work independently and as part of a team.

- Demonstrate your strong attention to detail and commitment to quality.

Essential Experience Highlights for a Strong Cutting Inspector Resume

- Inspect raw materials, semi-finished products, and finished goods to ensure they meet specifications.

- Use specialized measuring tools and equipment to check dimensions, tolerances, and surface finishes.

- Identify and document any defects or non-conformances.

- Provide feedback to production staff to help improve quality and efficiency.

- Maintain inspection records and ensure compliance with quality standards.

- Train new cutting inspectors and provide ongoing support.

- Stay up-to-date on the latest cutting technologies and industry best practices.

Frequently Asked Questions (FAQ’s) For Cutting Inspector

What are the key responsibilities of a Cutting Inspector?

Cutting Inspectors are responsible for inspecting raw materials, semi-finished products, and finished goods to ensure they meet specifications. They use specialized measuring tools and equipment to check dimensions, tolerances, and surface finishes. They also identify and document any defects or non-conformances, and provide feedback to production staff to help improve quality and efficiency.

What are the qualifications for a Cutting Inspector?

Cutting Inspectors typically have a high school diploma or equivalent, and some may have a college degree in manufacturing engineering or a related field. They also have experience in using measuring tools and equipment, and have a strong understanding of engineering drawings and quality standards.

What are the career prospects for a Cutting Inspector?

Cutting Inspectors can advance to positions such as Quality Inspector, Manufacturing Engineer, or Production Supervisor. With additional experience and training, they can also become certified as a Certified Quality Inspector (CQI).

What are the challenges of being a Cutting Inspector?

Cutting Inspectors work in a fast-paced environment and must be able to meet deadlines. They also must be able to work independently and as part of a team, and must have a strong attention to detail.

What is the salary range for a Cutting Inspector?

The salary range for a Cutting Inspector varies depending on experience, location, and company size. According to Salary.com, the average salary for a Cutting Inspector in the United States is between $40,000 and $60,000 per year.

How can I become a Cutting Inspector?

To become a Cutting Inspector, you can start by getting a high school diploma or equivalent. You can also take courses in manufacturing engineering or a related field. Once you have some experience, you can apply for entry-level positions as a Cutting Inspector.