Are you a seasoned Cutting Supervisor seeking a new career path? Discover our professionally built Cutting Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

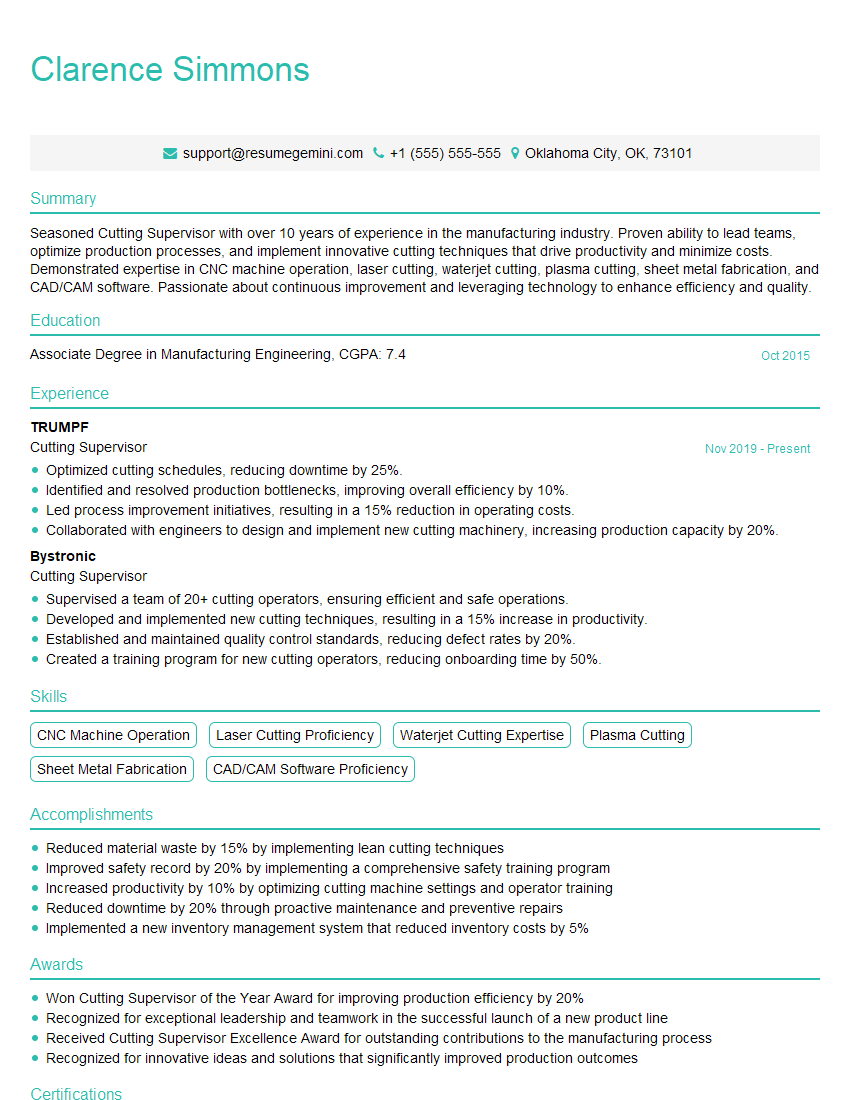

Clarence Simmons

Cutting Supervisor

Summary

Seasoned Cutting Supervisor with over 10 years of experience in the manufacturing industry. Proven ability to lead teams, optimize production processes, and implement innovative cutting techniques that drive productivity and minimize costs. Demonstrated expertise in CNC machine operation, laser cutting, waterjet cutting, plasma cutting, sheet metal fabrication, and CAD/CAM software. Passionate about continuous improvement and leveraging technology to enhance efficiency and quality.

Education

Associate Degree in Manufacturing Engineering

October 2015

Skills

- CNC Machine Operation

- Laser Cutting Proficiency

- Waterjet Cutting Expertise

- Plasma Cutting

- Sheet Metal Fabrication

- CAD/CAM Software Proficiency

Work Experience

Cutting Supervisor

- Optimized cutting schedules, reducing downtime by 25%.

- Identified and resolved production bottlenecks, improving overall efficiency by 10%.

- Led process improvement initiatives, resulting in a 15% reduction in operating costs.

- Collaborated with engineers to design and implement new cutting machinery, increasing production capacity by 20%.

Cutting Supervisor

- Supervised a team of 20+ cutting operators, ensuring efficient and safe operations.

- Developed and implemented new cutting techniques, resulting in a 15% increase in productivity.

- Established and maintained quality control standards, reducing defect rates by 20%.

- Created a training program for new cutting operators, reducing onboarding time by 50%.

Accomplishments

- Reduced material waste by 15% by implementing lean cutting techniques

- Improved safety record by 20% by implementing a comprehensive safety training program

- Increased productivity by 10% by optimizing cutting machine settings and operator training

- Reduced downtime by 20% through proactive maintenance and preventive repairs

- Implemented a new inventory management system that reduced inventory costs by 5%

Awards

- Won Cutting Supervisor of the Year Award for improving production efficiency by 20%

- Recognized for exceptional leadership and teamwork in the successful launch of a new product line

- Received Cutting Supervisor Excellence Award for outstanding contributions to the manufacturing process

- Recognized for innovative ideas and solutions that significantly improved production outcomes

Certificates

- Certified Cutting Supervisor (CCS)

- ISO 9001:2015

- OSHA 10-Hour Safety Certification

- AWS Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutting Supervisor

- Showcase your expertise in various cutting techniques, including CNC machine operation, laser cutting, waterjet cutting, and plasma cutting.

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work on productivity, quality, and cost reduction.

- Highlight your leadership skills and ability to motivate a team of cutting operators to achieve exceptional results.

- Emphasize your commitment to safety and your knowledge of industry best practices for cutting operations.

- Include keywords relevant to the cutting supervisor role, such as CNC machining, laser cutting, quality control, and process improvement.

Essential Experience Highlights for a Strong Cutting Supervisor Resume

- Managed a team of 20+ cutting operators, providing guidance, training, and support to ensure safe and efficient operations.

- Developed and implemented new cutting techniques that increased productivity by 15% and reduced defect rates by 20%.

- Established and maintained rigorous quality control standards, resulting in a 20% reduction in defect rates.

- Created a comprehensive training program for new cutting operators, reducing onboarding time by 50%.

- Optimized cutting schedules to minimize downtime by 25% and maximize machine utilization.

- Identified and resolved production bottlenecks, leading to a 10% improvement in overall efficiency.

- Led process improvement initiatives that resulted in a 15% reduction in operating costs.

- Collaborated with engineers to design and implement new cutting machinery, increasing production capacity by 20%.

Frequently Asked Questions (FAQ’s) For Cutting Supervisor

What are the primary responsibilities of a cutting supervisor?

Cutting supervisors are responsible for overseeing cutting operations, including managing a team of cutting operators, implementing new cutting techniques, establishing quality control standards, optimizing production schedules, and resolving production bottlenecks. They also lead process improvement initiatives and collaborate with engineers to design and implement new cutting machinery.

What are the most important skills for a cutting supervisor?

Essential skills for a cutting supervisor include expertise in CNC machine operation, laser cutting, waterjet cutting, plasma cutting, sheet metal fabrication, and CAD/CAM software. They must also possess strong leadership and communication skills, as well as a deep understanding of quality control and safety protocols.

What is the career path for a cutting supervisor?

Cutting supervisors can advance their careers by becoming production managers, operations managers, or even plant managers. With additional education and experience, they may also pursue roles in engineering or quality management.

What are the challenges faced by cutting supervisors?

Cutting supervisors face challenges such as increasing production demands, the need to improve efficiency and quality, and the constant need to stay abreast of new cutting technologies. They must also be able to effectively manage a team of cutting operators and maintain a safe and productive work environment.

What are the rewards of being a cutting supervisor?

Cutting supervisors enjoy the rewards of working in a dynamic and challenging industry. They have the opportunity to make a significant impact on their company’s success by improving productivity, reducing costs, and ensuring the quality of their products. They also enjoy the satisfaction of leading a team of skilled professionals and developing their careers in the manufacturing industry.

What is the job outlook for cutting supervisors?

The job outlook for cutting supervisors is expected to grow faster than average in the coming years. As the manufacturing industry continues to grow, there will be an increasing demand for skilled cutting supervisors who can manage and optimize cutting operations.

What are the different types of cutting operations?

There are several different types of cutting operations, including CNC machining, laser cutting, waterjet cutting, and plasma cutting. Each type of cutting operation has its own advantages and disadvantages, and the choice of cutting method depends on the specific application.

What are the safety considerations for cutting operations?

Cutting operations can be hazardous, and it is important to follow all safety protocols. This includes wearing appropriate safety gear, such as safety glasses, gloves, and hearing protection. It is also important to be aware of the potential hazards of the cutting equipment and to operate it safely.