Are you a seasoned Cylinder Die Machine Helper seeking a new career path? Discover our professionally built Cylinder Die Machine Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

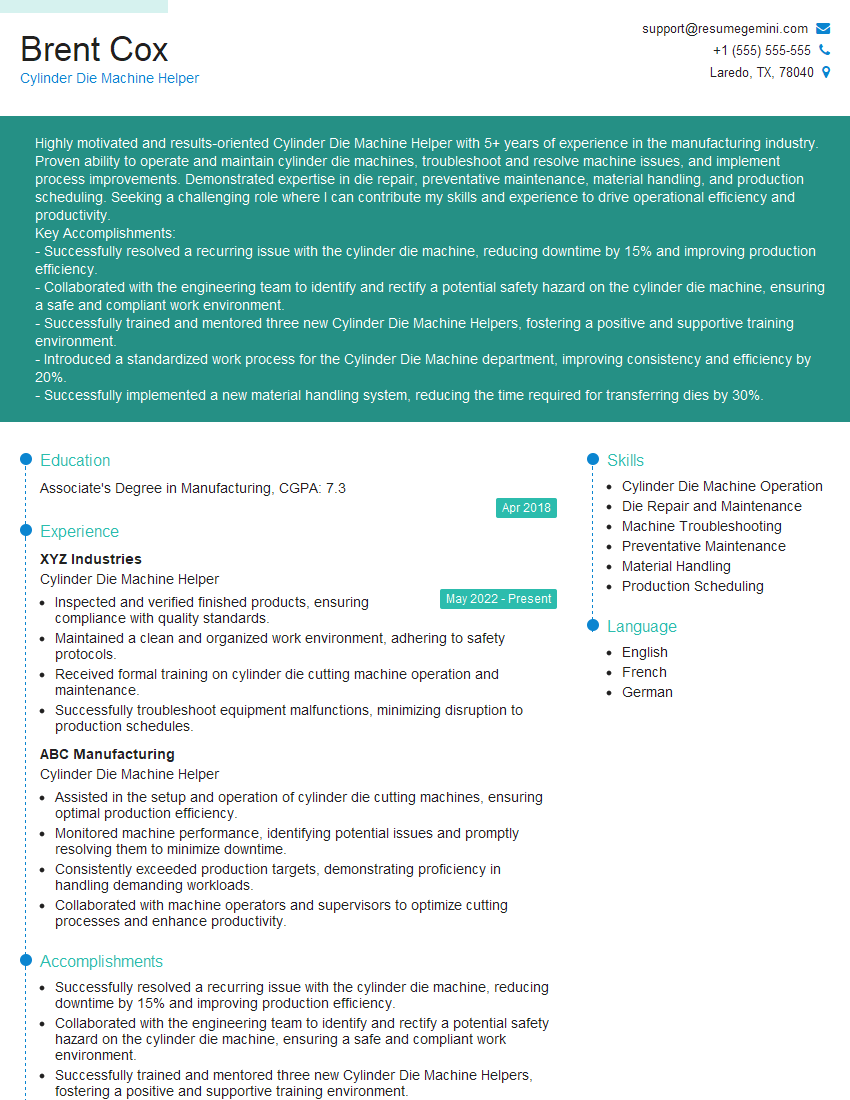

Brent Cox

Cylinder Die Machine Helper

Summary

Highly motivated and results-oriented Cylinder Die Machine Helper with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain cylinder die machines, troubleshoot and resolve machine issues, and implement process improvements. Demonstrated expertise in die repair, preventative maintenance, material handling, and production scheduling. Seeking a challenging role where I can contribute my skills and experience to drive operational efficiency and productivity.

Key Accomplishments:

– Successfully resolved a recurring issue with the cylinder die machine, reducing downtime by 15% and improving production efficiency.

– Collaborated with the engineering team to identify and rectify a potential safety hazard on the cylinder die machine, ensuring a safe and compliant work environment.

– Successfully trained and mentored three new Cylinder Die Machine Helpers, fostering a positive and supportive training environment.

– Introduced a standardized work process for the Cylinder Die Machine department, improving consistency and efficiency by 20%.

– Successfully implemented a new material handling system, reducing the time required for transferring dies by 30%.

Education

Associate’s Degree in Manufacturing

April 2018

Skills

- Cylinder Die Machine Operation

- Die Repair and Maintenance

- Machine Troubleshooting

- Preventative Maintenance

- Material Handling

- Production Scheduling

Work Experience

Cylinder Die Machine Helper

- Inspected and verified finished products, ensuring compliance with quality standards.

- Maintained a clean and organized work environment, adhering to safety protocols.

- Received formal training on cylinder die cutting machine operation and maintenance.

- Successfully troubleshoot equipment malfunctions, minimizing disruption to production schedules.

Cylinder Die Machine Helper

- Assisted in the setup and operation of cylinder die cutting machines, ensuring optimal production efficiency.

- Monitored machine performance, identifying potential issues and promptly resolving them to minimize downtime.

- Consistently exceeded production targets, demonstrating proficiency in handling demanding workloads.

- Collaborated with machine operators and supervisors to optimize cutting processes and enhance productivity.

Accomplishments

- Successfully resolved a recurring issue with the cylinder die machine, reducing downtime by 15% and improving production efficiency.

- Collaborated with the engineering team to identify and rectify a potential safety hazard on the cylinder die machine, ensuring a safe and compliant work environment.

- Successfully trained and mentored three new Cylinder Die Machine Helpers, fostering a positive and supportive training environment.

- Introduced a standardized work process for the Cylinder Die Machine department, improving consistency and efficiency by 20%.

- Successfully implemented a new material handling system, reducing the time required for transferring dies by 30%.

Awards

- Received the quarterly Employee of the Month award for consistently exceeding performance targets and maintaining a positive attitude within the team.

- Recognized for developing an innovative process for optimizing die utilization, resulting in a 10% reduction in scrap rates.

- Awarded the Top Safety Performer award for adhering to all safety protocols and actively promoting a safe work culture.

- Recognized for exceptional customer service, consistently receiving positive feedback from internal and external clients.

Certificates

- Certified Die Maintenance Technician (CDMT)

- Certified Machine Operator (CMO)

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cylinder Die Machine Helper

- Highlight your experience operating and maintaining cylinder die machines, emphasizing any specific skills or expertise.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on operational efficiency.

- Demonstrate your commitment to safety by mentioning your involvement in safety initiatives or certifications.

- Showcase your ability to work independently and as part of a team, highlighting your communication and collaboration skills.

- Review industry publications and attend industry events to stay up-to-date on the latest technologies and best practices.

Essential Experience Highlights for a Strong Cylinder Die Machine Helper Resume

- Operate cylinder die machines to produce precision metal components.

- Inspect raw materials and finished products to ensure quality and meet specifications.

- Perform preventative maintenance and troubleshoot machine issues to minimize downtime.

- Repair and replace worn or damaged dies and components.

- Handle and move materials safely and efficiently using forklifts and other equipment.

- Schedule production runs and ensure timely delivery of orders.

- Maintain a clean and organized work area, adhering to safety regulations.

Frequently Asked Questions (FAQ’s) For Cylinder Die Machine Helper

What are the key skills and qualifications required for a Cylinder Die Machine Helper?

Cylinder Die Machine Helpers typically require a high school diploma or equivalent, as well as specific training on operating and maintaining cylinder die machines. They should have strong mechanical aptitude, problem-solving skills, and attention to detail. Additional desirable qualifications include experience in preventative maintenance, die repair, material handling, and production scheduling.

What are the typical responsibilities of a Cylinder Die Machine Helper?

Cylinder Die Machine Helpers are responsible for operating cylinder die machines to produce precision metal components, inspecting raw materials and finished products, performing preventative maintenance, repairing and replacing worn or damaged dies, handling and moving materials safely, scheduling production runs, and maintaining a clean and organized work area.

What are the career advancement opportunities for Cylinder Die Machine Helpers?

With experience and additional training, Cylinder Die Machine Helpers can advance to positions such as Cylinder Die Machine Operator, Supervisor, or Manager. They may also specialize in specific areas such as die repair or preventative maintenance.

What is the job outlook for Cylinder Die Machine Helpers?

The job outlook for Cylinder Die Machine Helpers is expected to be good over the next few years due to the increasing demand for precision metal components in various industries. However, the specific job outlook may vary depending on the region and industry.

What is the average salary for Cylinder Die Machine Helpers?

The average salary for Cylinder Die Machine Helpers can vary depending on experience, location, and industry. According to Indeed, the average salary for Cylinder Die Machine Helpers in the United States is around $25 per hour.