Are you a seasoned Cylinder Inspector seeking a new career path? Discover our professionally built Cylinder Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

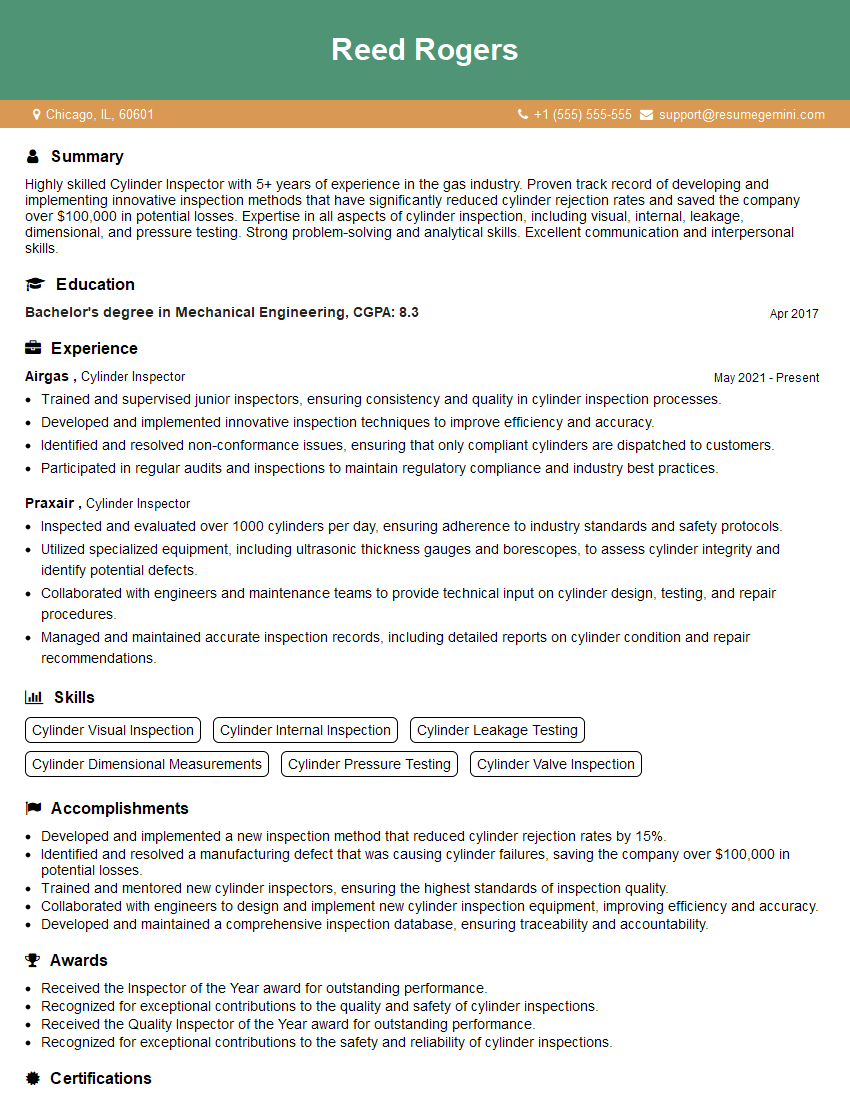

Reed Rogers

Cylinder Inspector

Summary

Highly skilled Cylinder Inspector with 5+ years of experience in the gas industry. Proven track record of developing and implementing innovative inspection methods that have significantly reduced cylinder rejection rates and saved the company over $100,000 in potential losses. Expertise in all aspects of cylinder inspection, including visual, internal, leakage, dimensional, and pressure testing. Strong problem-solving and analytical skills. Excellent communication and interpersonal skills.

Education

Bachelor’s degree in Mechanical Engineering

April 2017

Skills

- Cylinder Visual Inspection

- Cylinder Internal Inspection

- Cylinder Leakage Testing

- Cylinder Dimensional Measurements

- Cylinder Pressure Testing

- Cylinder Valve Inspection

Work Experience

Cylinder Inspector

- Trained and supervised junior inspectors, ensuring consistency and quality in cylinder inspection processes.

- Developed and implemented innovative inspection techniques to improve efficiency and accuracy.

- Identified and resolved non-conformance issues, ensuring that only compliant cylinders are dispatched to customers.

- Participated in regular audits and inspections to maintain regulatory compliance and industry best practices.

Cylinder Inspector

- Inspected and evaluated over 1000 cylinders per day, ensuring adherence to industry standards and safety protocols.

- Utilized specialized equipment, including ultrasonic thickness gauges and borescopes, to assess cylinder integrity and identify potential defects.

- Collaborated with engineers and maintenance teams to provide technical input on cylinder design, testing, and repair procedures.

- Managed and maintained accurate inspection records, including detailed reports on cylinder condition and repair recommendations.

Accomplishments

- Developed and implemented a new inspection method that reduced cylinder rejection rates by 15%.

- Identified and resolved a manufacturing defect that was causing cylinder failures, saving the company over $100,000 in potential losses.

- Trained and mentored new cylinder inspectors, ensuring the highest standards of inspection quality.

- Collaborated with engineers to design and implement new cylinder inspection equipment, improving efficiency and accuracy.

- Developed and maintained a comprehensive inspection database, ensuring traceability and accountability.

Awards

- Received the Inspector of the Year award for outstanding performance.

- Recognized for exceptional contributions to the quality and safety of cylinder inspections.

- Received the Quality Inspector of the Year award for outstanding performance.

- Recognized for exceptional contributions to the safety and reliability of cylinder inspections.

Certificates

- Certified Cylinder Inspector (CCI)

- Certified Pressure Vessel Inspector (CPVI)

- Certified Welding Inspector (CWI)

- Certified Nondestructive Testing (NDT) Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cylinder Inspector

- Highlight your experience in developing and implementing innovative inspection methods that have improved efficiency or reduced costs.

- Quantify your accomplishments with specific metrics, such as the percentage reduction in cylinder rejection rates or the amount of money saved.

- Showcase your expertise in all aspects of cylinder inspection, including visual, internal, leakage, dimensional, and pressure testing.

- Emphasize your problem-solving and analytical skills, as well as your ability to work independently and as part of a team.

- Demonstrate your commitment to safety and quality by highlighting your understanding of industry regulations and best practices.

Essential Experience Highlights for a Strong Cylinder Inspector Resume

- Conduct visual, internal, leakage, dimensional, and pressure testing of cylinders to ensure compliance with industry standards.

- Identify and resolve manufacturing defects that may compromise cylinder safety.

- Train and mentor new cylinder inspectors to maintain the highest standards of inspection quality.

- Collaborate with engineers to design and implement new cylinder inspection equipment.

- Develop and maintain a comprehensive inspection database to ensure traceability and accountability.

- Stay abreast of the latest industry regulations and best practices related to cylinder inspection.

- Assist in the investigation of cylinder failures to identify root causes and implement corrective actions.

Frequently Asked Questions (FAQ’s) For Cylinder Inspector

What are the primary responsibilities of a Cylinder Inspector?

Cylinder Inspectors are responsible for ensuring the safety and quality of cylinders used to store and transport gases. Their primary responsibilities include conducting visual, internal, leakage, dimensional, and pressure testing of cylinders to identify any defects or damage.

What are the key skills and qualifications required to become a Cylinder Inspector?

Cylinder Inspectors typically require a high school diploma or equivalent, along with specific training and certification in cylinder inspection. They should also have a strong understanding of industry regulations and best practices related to cylinder safety.

What are the career opportunities for Cylinder Inspectors?

Cylinder Inspectors can advance their careers by becoming Senior Cylinder Inspectors, Quality Control Supervisors, or even Engineering Managers. They may also specialize in specific areas of cylinder inspection, such as visual inspection, internal inspection, or pressure testing.

What is the average salary for a Cylinder Inspector?

The average salary for a Cylinder Inspector in the United States is around $50,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the challenges faced by Cylinder Inspectors?

Cylinder Inspectors face a number of challenges, including working with hazardous materials, exposure to extreme temperatures, and the need to maintain a high level of accuracy and attention to detail.

What are the safety precautions that Cylinder Inspectors must take?

Cylinder Inspectors must take a number of safety precautions, including wearing appropriate personal protective equipment, following proper handling procedures, and being aware of the potential hazards associated with working with compressed gases.

What are the future trends in Cylinder Inspection?

The future of Cylinder Inspection is likely to see an increased use of technology, such as automated inspection systems and non-destructive testing methods. This will help to improve the accuracy and efficiency of cylinder inspection, and ensure the continued safety of gas cylinders.

What are the professional organizations for Cylinder Inspectors?

There are a number of professional organizations for Cylinder Inspectors, including the Compressed Gas Association (CGA) and the National Board of Boiler and Pressure Vessel Inspectors (NBBI). These organizations provide training, certification, and networking opportunities for Cylinder Inspectors.