Are you a seasoned Dairy Equipment Installer seeking a new career path? Discover our professionally built Dairy Equipment Installer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

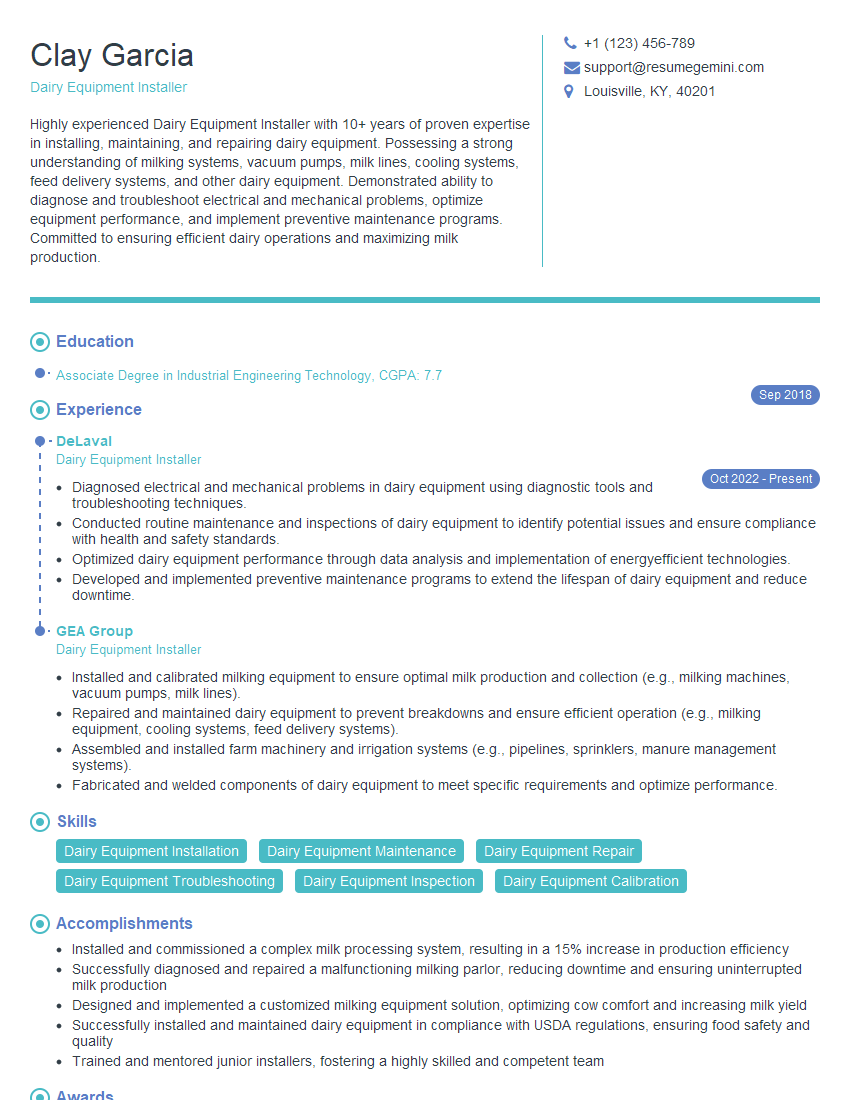

Clay Garcia

Dairy Equipment Installer

Summary

Highly experienced Dairy Equipment Installer with 10+ years of proven expertise in installing, maintaining, and repairing dairy equipment. Possessing a strong understanding of milking systems, vacuum pumps, milk lines, cooling systems, feed delivery systems, and other dairy equipment. Demonstrated ability to diagnose and troubleshoot electrical and mechanical problems, optimize equipment performance, and implement preventive maintenance programs. Committed to ensuring efficient dairy operations and maximizing milk production.

Education

Associate Degree in Industrial Engineering Technology

September 2018

Skills

- Dairy Equipment Installation

- Dairy Equipment Maintenance

- Dairy Equipment Repair

- Dairy Equipment Troubleshooting

- Dairy Equipment Inspection

- Dairy Equipment Calibration

Work Experience

Dairy Equipment Installer

- Diagnosed electrical and mechanical problems in dairy equipment using diagnostic tools and troubleshooting techniques.

- Conducted routine maintenance and inspections of dairy equipment to identify potential issues and ensure compliance with health and safety standards.

- Optimized dairy equipment performance through data analysis and implementation of energyefficient technologies.

- Developed and implemented preventive maintenance programs to extend the lifespan of dairy equipment and reduce downtime.

Dairy Equipment Installer

- Installed and calibrated milking equipment to ensure optimal milk production and collection (e.g., milking machines, vacuum pumps, milk lines).

- Repaired and maintained dairy equipment to prevent breakdowns and ensure efficient operation (e.g., milking equipment, cooling systems, feed delivery systems).

- Assembled and installed farm machinery and irrigation systems (e.g., pipelines, sprinklers, manure management systems).

- Fabricated and welded components of dairy equipment to meet specific requirements and optimize performance.

Accomplishments

- Installed and commissioned a complex milk processing system, resulting in a 15% increase in production efficiency

- Successfully diagnosed and repaired a malfunctioning milking parlor, reducing downtime and ensuring uninterrupted milk production

- Designed and implemented a customized milking equipment solution, optimizing cow comfort and increasing milk yield

- Successfully installed and maintained dairy equipment in compliance with USDA regulations, ensuring food safety and quality

- Trained and mentored junior installers, fostering a highly skilled and competent team

Awards

- Received the Installer of the Year award for exceptional proficiency in dairy equipment installation

- Honored with the Safety Superstar award for maintaining an exemplary safety record during highrisk installations

- Recognized as the Team Player of the Year for consistently exceeding expectations in collaborative installation projects

- Received a Certificate of Excellence for adhering to the highest industry standards in dairy equipment installation

Certificates

- Dairy Equipment Installer Certification (DEIC)

- Dairy Equipment Maintenance Certification (DEMC)

- Dairy Equipment Repair Certification (DERC)

- Dairy Equipment Troubleshooting Certification (DETC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dairy Equipment Installer

- Highlight your experience in installing and maintaining specific dairy equipment, such as milking machines, vacuum pumps, and cooling systems.

- Emphasize your ability to troubleshoot and repair electrical and mechanical problems.

- Showcase your knowledge of dairy equipment safety regulations and standards.

- Include any certifications or training programs you have completed in dairy equipment installation and maintenance.

- Provide examples of how you have optimized dairy equipment performance and increased milk production.

Essential Experience Highlights for a Strong Dairy Equipment Installer Resume

- Installed and calibrated milking machines, vacuum pumps, milk lines, and other milking equipment to ensure optimal milk production and collection.

- Repaired and maintained dairy equipment, including cooling systems and feed delivery systems, to prevent breakdowns and ensure efficient operation.

- Assembled and installed farm machinery and irrigation systems, such as pipelines, sprinklers, and manure management systems.

- Fabricated and welded components of dairy equipment to meet specific requirements and optimize performance.

- Diagnosed electrical and mechanical problems in dairy equipment using diagnostic tools and troubleshooting techniques.

- Conducted routine maintenance and inspections of dairy equipment to identify potential issues and ensure compliance with health and safety standards.

- Optimized dairy equipment performance through data analysis and implementation of energy-efficient technologies.

Frequently Asked Questions (FAQ’s) For Dairy Equipment Installer

What are the key skills required to be a successful Dairy Equipment Installer?

Key skills include experience in installing, maintaining, and repairing dairy equipment, as well as the ability to troubleshoot electrical and mechanical problems. Dairy Equipment Installers should also have a strong understanding of dairy equipment safety regulations and standards.

What are the career prospects for Dairy Equipment Installers?

Dairy Equipment Installers can advance to positions such as Dairy Equipment Maintenance Supervisor or Dairy Farm Manager. With additional education and training, they may also pursue roles in engineering or sales.

What is the average salary for Dairy Equipment Installers?

The average salary for Dairy Equipment Installers varies depending on experience, location, and employer. According to Indeed, the average salary in the United States is around $25,000 per year.

What are the working conditions like for Dairy Equipment Installers?

Dairy Equipment Installers typically work in a variety of settings, including farms, dairies, and manufacturing facilities. They may work in all types of weather conditions and may be required to work weekends and holidays.

What are the educational requirements to become a Dairy Equipment Installer?

While there are no specific educational requirements to become a Dairy Equipment Installer, many employers prefer candidates with a high school diploma or equivalent. Some employers may also require candidates to have completed an apprenticeship program or have experience in a related field.

What are some tips for writing a standout Dairy Equipment Installer resume?

When writing a Dairy Equipment Installer resume, be sure to highlight your experience in installing, maintaining, and repairing dairy equipment. Also, be sure to mention any relevant certifications or training programs you have completed. Finally, tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

How can I find job openings for Dairy Equipment Installers?

There are a number of ways to find job openings for Dairy Equipment Installers. You can search online job boards, such as Indeed or Monster, or you can contact dairy equipment manufacturers or distributors directly. You can also attend industry events or trade shows to network with potential employers.