Are you a seasoned Dairy Equipment Mechanic seeking a new career path? Discover our professionally built Dairy Equipment Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

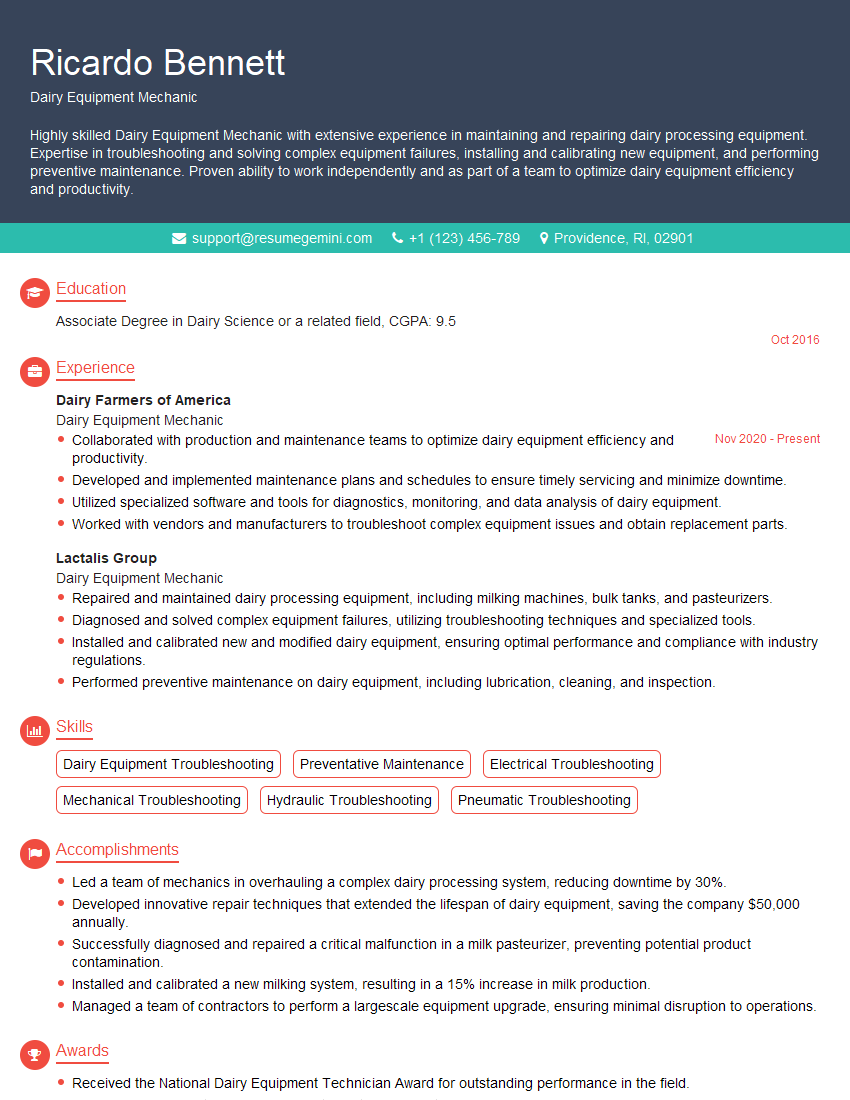

Ricardo Bennett

Dairy Equipment Mechanic

Summary

Highly skilled Dairy Equipment Mechanic with extensive experience in maintaining and repairing dairy processing equipment. Expertise in troubleshooting and solving complex equipment failures, installing and calibrating new equipment, and performing preventive maintenance. Proven ability to work independently and as part of a team to optimize dairy equipment efficiency and productivity.

Education

Associate Degree in Dairy Science or a related field

October 2016

Skills

- Dairy Equipment Troubleshooting

- Preventative Maintenance

- Electrical Troubleshooting

- Mechanical Troubleshooting

- Hydraulic Troubleshooting

- Pneumatic Troubleshooting

Work Experience

Dairy Equipment Mechanic

- Collaborated with production and maintenance teams to optimize dairy equipment efficiency and productivity.

- Developed and implemented maintenance plans and schedules to ensure timely servicing and minimize downtime.

- Utilized specialized software and tools for diagnostics, monitoring, and data analysis of dairy equipment.

- Worked with vendors and manufacturers to troubleshoot complex equipment issues and obtain replacement parts.

Dairy Equipment Mechanic

- Repaired and maintained dairy processing equipment, including milking machines, bulk tanks, and pasteurizers.

- Diagnosed and solved complex equipment failures, utilizing troubleshooting techniques and specialized tools.

- Installed and calibrated new and modified dairy equipment, ensuring optimal performance and compliance with industry regulations.

- Performed preventive maintenance on dairy equipment, including lubrication, cleaning, and inspection.

Accomplishments

- Led a team of mechanics in overhauling a complex dairy processing system, reducing downtime by 30%.

- Developed innovative repair techniques that extended the lifespan of dairy equipment, saving the company $50,000 annually.

- Successfully diagnosed and repaired a critical malfunction in a milk pasteurizer, preventing potential product contamination.

- Installed and calibrated a new milking system, resulting in a 15% increase in milk production.

- Managed a team of contractors to perform a largescale equipment upgrade, ensuring minimal disruption to operations.

Awards

- Received the National Dairy Equipment Technician Award for outstanding performance in the field.

- Recognized by industry peers for exceptional troubleshooting and repair skills.

- Awarded employee of the month for outstanding contributions to the team.

- Received a safety award for exemplary safety practices and contributions to the workplace.

Certificates

- Certified Dairy Equipment Technician

- Certified PLC Programmer

- Certified VFD Programmer

- OSHA 30-Hour Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dairy Equipment Mechanic

- Highlight your experience and skills in dairy equipment repair and maintenance.

- Showcase your problem-solving abilities and troubleshooting expertise.

- Emphasize your knowledge of dairy processing equipment and industry regulations.

- Quantify your accomplishments and provide specific examples of how you have improved dairy equipment efficiency and productivity.

Essential Experience Highlights for a Strong Dairy Equipment Mechanic Resume

- Repair and maintain dairy processing equipment, including milking machines, bulk tanks, and pasteurizers.

- Diagnose and solve complex equipment failures, utilizing troubleshooting techniques and specialized tools.

- Install and calibrate new and modified dairy equipment, ensuring optimal performance and compliance with industry regulations.

- Perform preventive maintenance on dairy equipment, including lubrication, cleaning, and inspection.

- Collaborate with production and maintenance teams to optimize dairy equipment efficiency and productivity.

- Develop and implement maintenance plans and schedules to ensure timely servicing and minimize downtime.

Frequently Asked Questions (FAQ’s) For Dairy Equipment Mechanic

What are the key skills required for a Dairy Equipment Mechanic?

Dairy Equipment Troubleshooting, Preventative Maintenance, Electrical Troubleshooting, Mechanical Troubleshooting, Hydraulic Troubleshooting, Pneumatic Troubleshooting.

What are the common responsibilities of a Dairy Equipment Mechanic?

Repairing and maintaining dairy processing equipment, diagnosing and solving complex equipment failures, installing and calibrating new equipment, performing preventive maintenance, and collaborating with production and maintenance teams.

What are the qualifications required to become a Dairy Equipment Mechanic?

Associate Degree in Dairy Science or a related field, with experience in dairy equipment repair and maintenance

What are the career prospects for a Dairy Equipment Mechanic?

Dairy Equipment Mechanics can advance to positions such as Dairy Equipment Maintenance Supervisor, Dairy Plant Manager, or Technical Support Specialist.

What is the average salary for a Dairy Equipment Mechanic?

The average salary for a Dairy Equipment Mechanic in the United States is around $50,000 per year.

What are the major companies that hire Dairy Equipment Mechanics?

Dairy Farmers of America, Lactalis Group, Schreiber Foods, Danone, Nestlé