Are you a seasoned Dairy Equipment Repairer seeking a new career path? Discover our professionally built Dairy Equipment Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

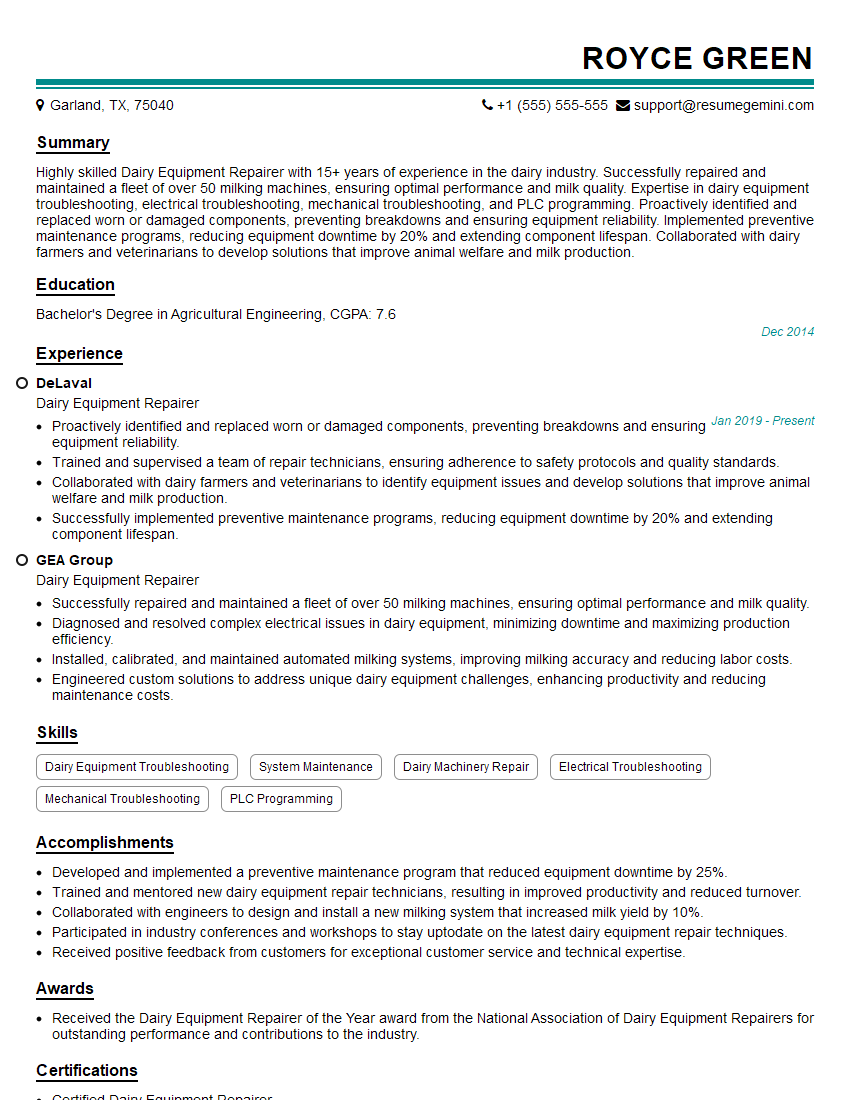

Royce Green

Dairy Equipment Repairer

Summary

Highly skilled Dairy Equipment Repairer with 15+ years of experience in the dairy industry. Successfully repaired and maintained a fleet of over 50 milking machines, ensuring optimal performance and milk quality. Expertise in dairy equipment troubleshooting, electrical troubleshooting, mechanical troubleshooting, and PLC programming. Proactively identified and replaced worn or damaged components, preventing breakdowns and ensuring equipment reliability. Implemented preventive maintenance programs, reducing equipment downtime by 20% and extending component lifespan. Collaborated with dairy farmers and veterinarians to develop solutions that improve animal welfare and milk production.

Education

Bachelor’s Degree in Agricultural Engineering

December 2014

Skills

- Dairy Equipment Troubleshooting

- System Maintenance

- Dairy Machinery Repair

- Electrical Troubleshooting

- Mechanical Troubleshooting

- PLC Programming

Work Experience

Dairy Equipment Repairer

- Proactively identified and replaced worn or damaged components, preventing breakdowns and ensuring equipment reliability.

- Trained and supervised a team of repair technicians, ensuring adherence to safety protocols and quality standards.

- Collaborated with dairy farmers and veterinarians to identify equipment issues and develop solutions that improve animal welfare and milk production.

- Successfully implemented preventive maintenance programs, reducing equipment downtime by 20% and extending component lifespan.

Dairy Equipment Repairer

- Successfully repaired and maintained a fleet of over 50 milking machines, ensuring optimal performance and milk quality.

- Diagnosed and resolved complex electrical issues in dairy equipment, minimizing downtime and maximizing production efficiency.

- Installed, calibrated, and maintained automated milking systems, improving milking accuracy and reducing labor costs.

- Engineered custom solutions to address unique dairy equipment challenges, enhancing productivity and reducing maintenance costs.

Accomplishments

- Developed and implemented a preventive maintenance program that reduced equipment downtime by 25%.

- Trained and mentored new dairy equipment repair technicians, resulting in improved productivity and reduced turnover.

- Collaborated with engineers to design and install a new milking system that increased milk yield by 10%.

- Participated in industry conferences and workshops to stay uptodate on the latest dairy equipment repair techniques.

- Received positive feedback from customers for exceptional customer service and technical expertise.

Awards

- Received the Dairy Equipment Repairer of the Year award from the National Association of Dairy Equipment Repairers for outstanding performance and contributions to the industry.

Certificates

- Certified Dairy Equipment Repairer

- Certified PLC Programmer

- Certified Industrial Automation Technician

- Certified Electrical Safety Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dairy Equipment Repairer

- Highlight your experience in dairy equipment maintenance and repair.

- Showcase your troubleshooting skills and ability to resolve complex issues.

- Emphasize your knowledge of electrical and mechanical systems.

- Demonstrate your proficiency in PLC programming and equipment automation.

- Include quantifiable results to showcase your impact on milk quality and production efficiency.

Essential Experience Highlights for a Strong Dairy Equipment Repairer Resume

- Repair and maintain dairy equipment, including milking machines, bulk tanks, and automated systems.

- Inspect and test equipment to identify problems and ensure compliance.

- Troubleshoot and resolve electrical, mechanical, and PLC issues.

- Calibrate and adjust equipment to ensure precision and accuracy.

- Install new equipment and modify or upgrade existing systems.

- Provide technical support and training to dairy farmers and staff.

- Perform preventive maintenance and lubrication tasks to extend equipment life.

Frequently Asked Questions (FAQ’s) For Dairy Equipment Repairer

What are the key responsibilities of a Dairy Equipment Repairer?

Dairy Equipment Repairers are responsible for installing, maintaining, and repairing dairy equipment, including milking machines, bulk tanks, and automated systems. They inspect and test equipment to identify problems, troubleshoot and resolve electrical, mechanical, and PLC issues, calibrate and adjust equipment, install and upgrade systems, and provide technical support and training to dairy farmers and staff.

What skills are required to be a Dairy Equipment Repairer?

Dairy Equipment Repairers typically need a high school diploma or equivalent and specialized training or experience in dairy equipment maintenance and repair. They should have strong mechanical and electrical skills, be able to read and interpret blueprints and schematics, and have a basic understanding of PLC programming. Excellent communication and interpersonal skills are also essential.

What is the job outlook for Dairy Equipment Repairers?

The job outlook for Dairy Equipment Repairers is expected to be good over the next few years. The demand for qualified Dairy Equipment Repairers is expected to increase as dairy farms become more automated and reliant on technology.

What is the average salary for a Dairy Equipment Repairer?

The average salary for a Dairy Equipment Repairer is around $50,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the benefits of working as a Dairy Equipment Repairer?

Dairy Equipment Repairers enjoy a number of benefits, including a competitive salary, job security, and the opportunity to work with cutting-edge technology. They also have the opportunity to make a real difference in the dairy industry by helping to ensure that dairy farms operate efficiently and produce high-quality milk.

What are the challenges of working as a Dairy Equipment Repairer?

Dairy Equipment Repairers may face a number of challenges, including working in a physically demanding environment, dealing with tight deadlines, and being on call for emergencies. They may also need to work in extreme weather conditions.

What advice would you give to someone who wants to become a Dairy Equipment Repairer?

If you are interested in becoming a Dairy Equipment Repairer, I recommend that you get as much hands-on experience as possible. You can do this by working on your own equipment or volunteering your services to a local dairy farm. You should also consider taking some courses in dairy equipment maintenance and repair.