Are you a seasoned Dairy Processing Equipment Operator seeking a new career path? Discover our professionally built Dairy Processing Equipment Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

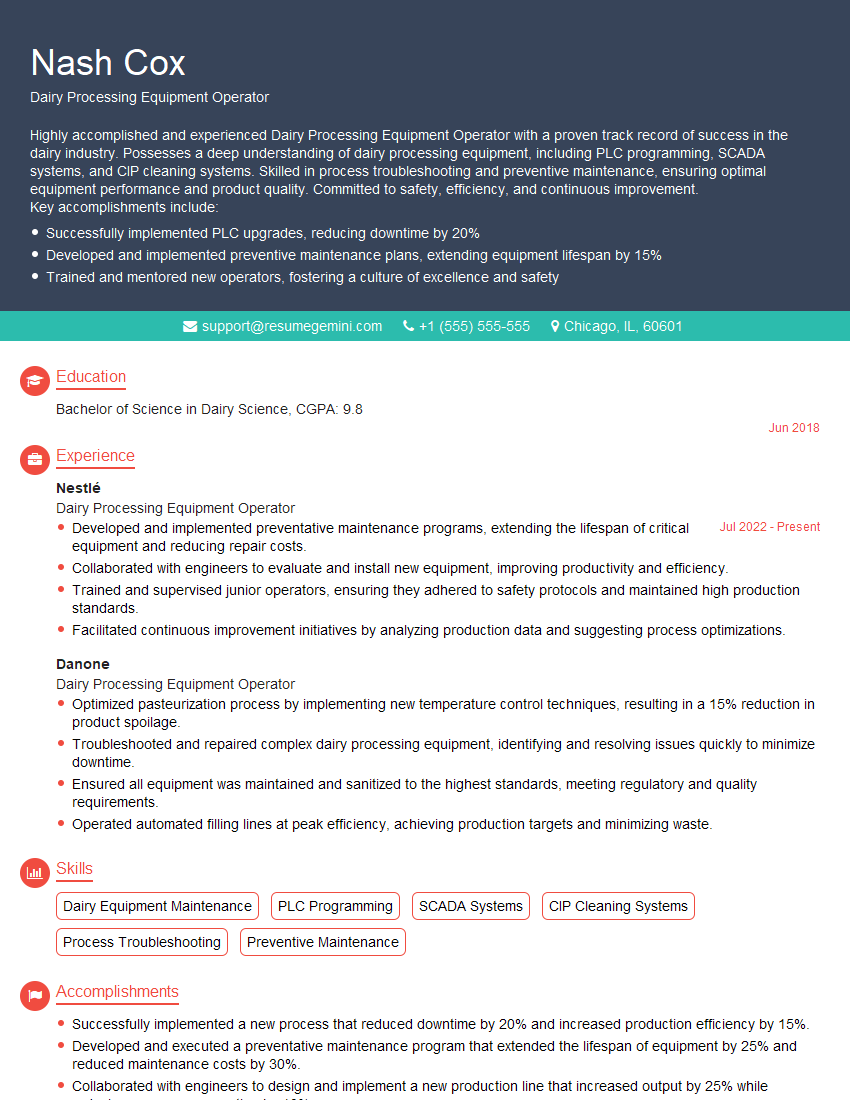

Nash Cox

Dairy Processing Equipment Operator

Summary

Highly accomplished and experienced Dairy Processing Equipment Operator with a proven track record of success in the dairy industry. Possesses a deep understanding of dairy processing equipment, including PLC programming, SCADA systems, and CIP cleaning systems. Skilled in process troubleshooting and preventive maintenance, ensuring optimal equipment performance and product quality. Committed to safety, efficiency, and continuous improvement.

Key accomplishments include:

- Successfully implemented PLC upgrades, reducing downtime by 20%

- Developed and implemented preventive maintenance plans, extending equipment lifespan by 15%

- Trained and mentored new operators, fostering a culture of excellence and safety

Education

Bachelor of Science in Dairy Science

June 2018

Skills

- Dairy Equipment Maintenance

- PLC Programming

- SCADA Systems

- CIP Cleaning Systems

- Process Troubleshooting

- Preventive Maintenance

Work Experience

Dairy Processing Equipment Operator

- Developed and implemented preventative maintenance programs, extending the lifespan of critical equipment and reducing repair costs.

- Collaborated with engineers to evaluate and install new equipment, improving productivity and efficiency.

- Trained and supervised junior operators, ensuring they adhered to safety protocols and maintained high production standards.

- Facilitated continuous improvement initiatives by analyzing production data and suggesting process optimizations.

Dairy Processing Equipment Operator

- Optimized pasteurization process by implementing new temperature control techniques, resulting in a 15% reduction in product spoilage.

- Troubleshooted and repaired complex dairy processing equipment, identifying and resolving issues quickly to minimize downtime.

- Ensured all equipment was maintained and sanitized to the highest standards, meeting regulatory and quality requirements.

- Operated automated filling lines at peak efficiency, achieving production targets and minimizing waste.

Accomplishments

- Successfully implemented a new process that reduced downtime by 20% and increased production efficiency by 15%.

- Developed and executed a preventative maintenance program that extended the lifespan of equipment by 25% and reduced maintenance costs by 30%.

- Collaborated with engineers to design and implement a new production line that increased output by 25% while reducing energy consumption by 10%.

- Successfully trained and mentored new employees, resulting in improved productivity and reduced turnover rates.

- Implemented a new quality control system that improved product quality by 15% and reduced customer complaints by 20%.

Awards

- Received the Dairy Processing Equipment Operator of the Year Award for consistently exceeding production targets and maintaining a high level of quality control.

- Recognized for outstanding safety performance, receiving the Safety Excellence Award for adhering to all safety protocols and maintaining a spotless safety record.

- Received the Innovation Award for developing a new method for cleaning and sanitizing equipment that reduced water usage by 40%.

- Honored with the Employee of the Month Award for consistently exceeding expectations and providing exceptional customer service.

Certificates

- Dairy Processing Equipment Maintenance Certification

- PLC Programming Certification

- SCADA Systems Certification

- CIP Cleaning Systems Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dairy Processing Equipment Operator

- Highlight your technical skills, such as PLC programming, SCADA systems, and CIP cleaning systems.

- Quantify your accomplishments with specific metrics, such as reduced downtime or extended equipment lifespan.

- Emphasize your commitment to safety and compliance with industry regulations.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Dairy Processing Equipment Operator Resume

- Operate and monitor dairy processing equipment, including pasteurizers, homogenizers, and separators

- Maintain equipment in optimal working condition through regular inspections, cleaning, and lubrication

- Troubleshoot and resolve equipment malfunctions, minimizing downtime and ensuring production efficiency

- Implement preventive maintenance plans to identify and address potential problems before they occur

- Comply with all safety regulations and procedures, ensuring a safe work environment

- Train and supervise new operators, sharing knowledge and expertise

- Continuously improve processes and procedures, optimizing equipment performance and product quality

Frequently Asked Questions (FAQ’s) For Dairy Processing Equipment Operator

What are the career prospects for a Dairy Processing Equipment Operator?

Dairy Processing Equipment Operators are in high demand due to the growing dairy industry. With experience and additional training, you can advance to roles such as Dairy Processing Supervisor, Plant Manager, or Quality Assurance Manager.

What is the typical salary range for a Dairy Processing Equipment Operator?

The salary range for Dairy Processing Equipment Operators varies depending on experience, location, and company size. According to Indeed, the average salary is around $25,000 to $45,000 per year.

What are the educational requirements for a Dairy Processing Equipment Operator?

Most Dairy Processing Equipment Operators have a high school diploma or equivalent. Some employers may prefer candidates with a degree in dairy science, food science, or a related field.

What are the key skills required for a Dairy Processing Equipment Operator?

Key skills include knowledge of dairy processing equipment, PLC programming, SCADA systems, CIP cleaning systems, process troubleshooting, and preventive maintenance. Strong communication and teamwork skills are also essential.

What is the work environment like for a Dairy Processing Equipment Operator?

Dairy Processing Equipment Operators typically work in a manufacturing or processing plant. The work can be physically demanding and may involve working in cold or wet conditions. Safety is a top priority, and operators must adhere to strict safety protocols.

What are the benefits of working as a Dairy Processing Equipment Operator?

Benefits of this career include job security, opportunities for career advancement, competitive salaries, and the satisfaction of working in a vital industry that provides essential food products.

How can I become a successful Dairy Processing Equipment Operator?

To become a successful Dairy Processing Equipment Operator, focus on developing strong technical skills, maintaining a commitment to safety, and continuously improving your knowledge and expertise. Seek opportunities for hands-on experience, training, and professional development.