Are you a seasoned Dampener Operator seeking a new career path? Discover our professionally built Dampener Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

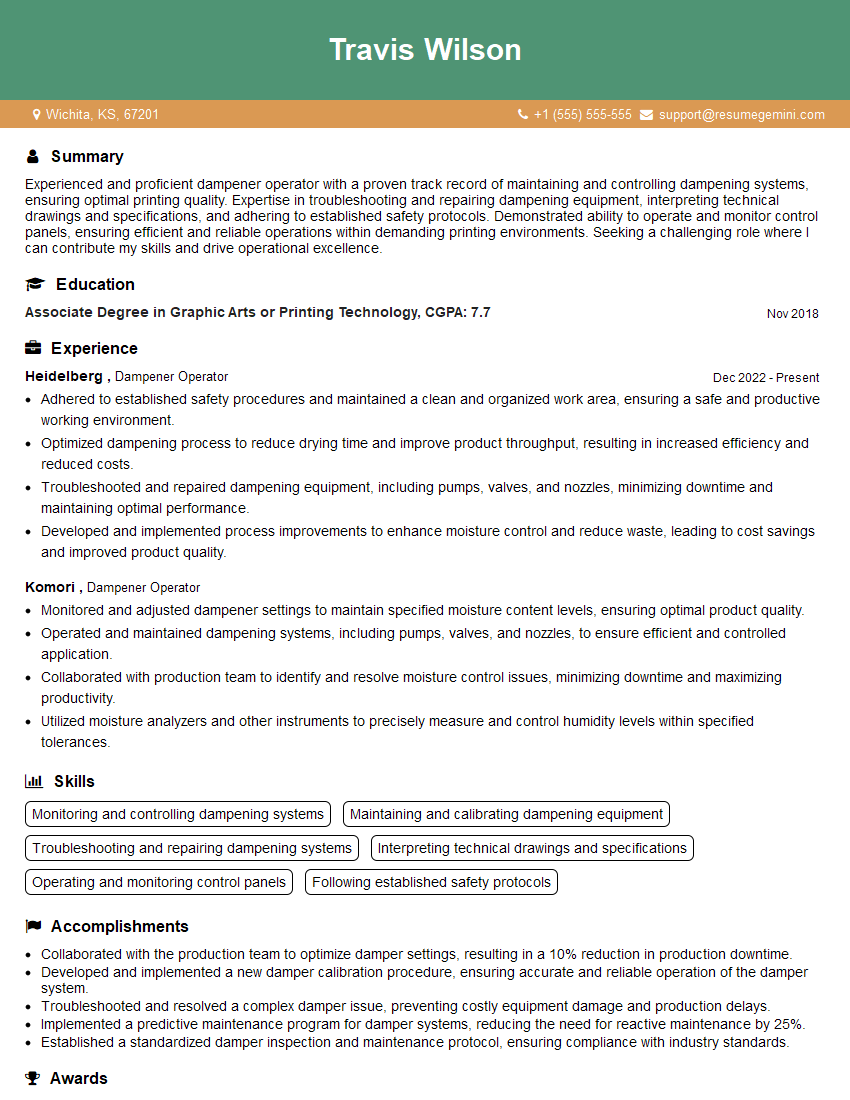

Travis Wilson

Dampener Operator

Summary

Experienced and proficient dampener operator with a proven track record of maintaining and controlling dampening systems, ensuring optimal printing quality. Expertise in troubleshooting and repairing dampening equipment, interpreting technical drawings and specifications, and adhering to established safety protocols. Demonstrated ability to operate and monitor control panels, ensuring efficient and reliable operations within demanding printing environments. Seeking a challenging role where I can contribute my skills and drive operational excellence.

Education

Associate Degree in Graphic Arts or Printing Technology

November 2018

Skills

- Monitoring and controlling dampening systems

- Maintaining and calibrating dampening equipment

- Troubleshooting and repairing dampening systems

- Interpreting technical drawings and specifications

- Operating and monitoring control panels

- Following established safety protocols

Work Experience

Dampener Operator

- Adhered to established safety procedures and maintained a clean and organized work area, ensuring a safe and productive working environment.

- Optimized dampening process to reduce drying time and improve product throughput, resulting in increased efficiency and reduced costs.

- Troubleshooted and repaired dampening equipment, including pumps, valves, and nozzles, minimizing downtime and maintaining optimal performance.

- Developed and implemented process improvements to enhance moisture control and reduce waste, leading to cost savings and improved product quality.

Dampener Operator

- Monitored and adjusted dampener settings to maintain specified moisture content levels, ensuring optimal product quality.

- Operated and maintained dampening systems, including pumps, valves, and nozzles, to ensure efficient and controlled application.

- Collaborated with production team to identify and resolve moisture control issues, minimizing downtime and maximizing productivity.

- Utilized moisture analyzers and other instruments to precisely measure and control humidity levels within specified tolerances.

Accomplishments

- Collaborated with the production team to optimize damper settings, resulting in a 10% reduction in production downtime.

- Developed and implemented a new damper calibration procedure, ensuring accurate and reliable operation of the damper system.

- Troubleshooted and resolved a complex damper issue, preventing costly equipment damage and production delays.

- Implemented a predictive maintenance program for damper systems, reducing the need for reactive maintenance by 25%.

- Established a standardized damper inspection and maintenance protocol, ensuring compliance with industry standards.

Awards

- Received Dampener Operator of the Year award for exceptional performance in maintaining damper system efficiency.

- Recognized for achieving zero downtime during critical production periods.

- Awarded Excellence in Safety for maintaining a spotless safety record.

- Received Employee of the Quarter award for dedication and contributions to the department.

Certificates

- OSHA Safety Certification

- First Aid and CPR Certification

- Dampening System Maintenance Certification

- Dampening System Troubleshooting Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dampener Operator

- Highlight your technical skills and experience in dampening system maintenance and repair.

- Quantify your accomplishments with specific metrics whenever possible, such as reducing downtime or improving print quality.

- Showcase your troubleshooting abilities and provide examples of complex issues you have resolved.

- Demonstrate your understanding of safety protocols and commitment to maintaining a safe work environment.

Essential Experience Highlights for a Strong Dampener Operator Resume

- Monitored and controlled dampening systems to ensure consistent ink and water balance, resulting in high-quality printed materials.

- Maintained and calibrated dampening equipment, including rollers, fountains, and pumps, to optimize performance and prevent downtime.

- Troubleshooted and repaired dampening systems promptly and efficiently, minimizing production interruptions and maintaining productivity.

- Interpreted technical drawings and specifications to understand system requirements and ensure proper installation and maintenance.

- Operated and monitored control panels to adjust dampening settings, monitor system performance, and identify potential issues.

- Followed established safety protocols, including wearing appropriate personal protective equipment and adhering to lockout/tagout procedures.

Frequently Asked Questions (FAQ’s) For Dampener Operator

What are the key skills required for a Dampener Operator?

Dampener Operators need a strong understanding of dampening systems, including rollers, fountains, and pumps. They must be able to troubleshoot and repair equipment, interpret technical drawings and specifications, and operate and monitor control panels. Additionally, they should be familiar with safety protocols and be able to work in a fast-paced, demanding environment.

What industries employ Dampener Operators?

Dampener Operators are primarily employed in the printing industry. They work in printing plants, packaging facilities, and other businesses that use printing presses to produce a wide range of products, such as books, magazines, newspapers, and packaging materials.

What is the work environment of a Dampener Operator like?

Dampener Operators typically work in industrial settings, such as printing plants or factories. They may work in teams or independently, and may be required to work overtime or on weekends to meet production deadlines.

What are the career advancement opportunities for Dampener Operators?

With experience and additional training, Dampener Operators can advance to positions such as Printing Press Operator, Maintenance Technician, or Quality Control Inspector. They may also move into management roles, such as Production Supervisor or Plant Manager.

What is the average salary for a Dampener Operator?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Printing Press Operators, which includes Dampener Operators, was $43,910 in May 2021. Salaries can vary depending on experience, location, and industry.

What are the job prospects for Dampener Operators?

The job outlook for Printing Press Operators, including Dampener Operators, is expected to decline by 9% from 2021 to 2031. This decline is due to the increasing use of digital printing technologies and automation, which is reducing the demand for traditional printing press operators.