Are you a seasoned Debridging Machine Operator seeking a new career path? Discover our professionally built Debridging Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

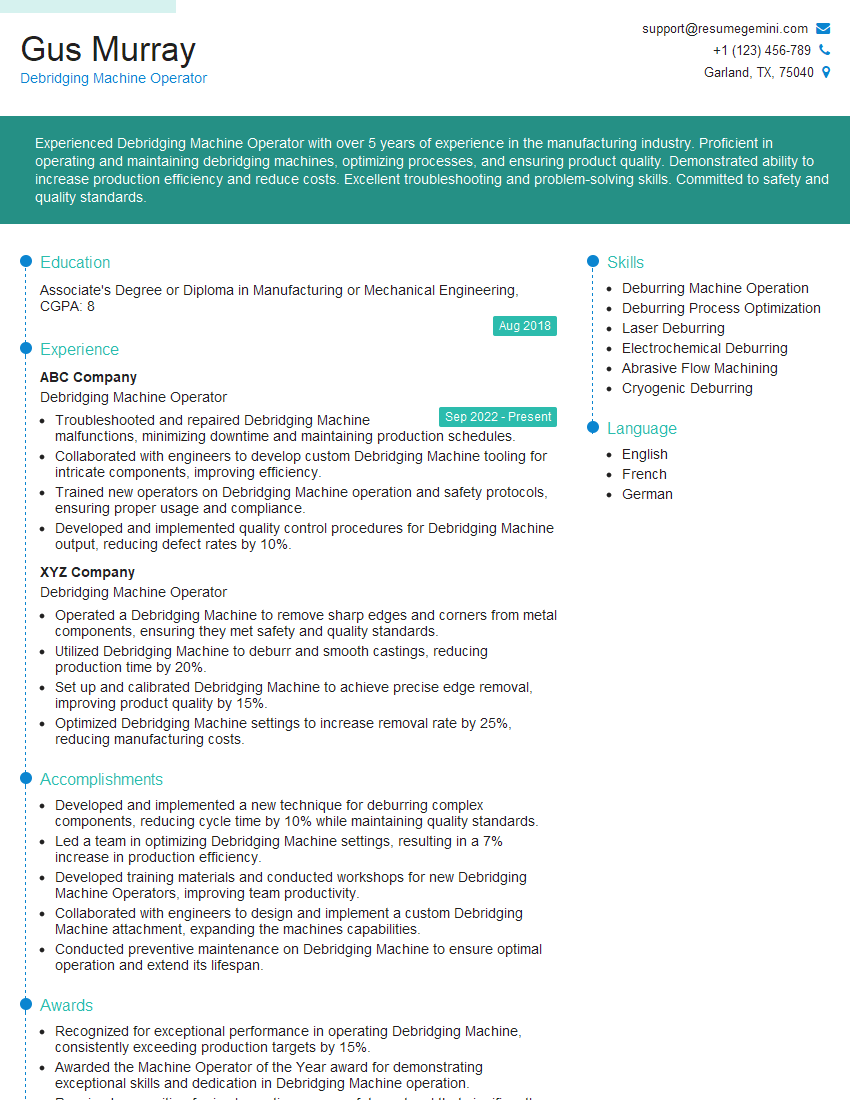

Gus Murray

Debridging Machine Operator

Summary

Experienced Debridging Machine Operator with over 5 years of experience in the manufacturing industry. Proficient in operating and maintaining debridging machines, optimizing processes, and ensuring product quality. Demonstrated ability to increase production efficiency and reduce costs. Excellent troubleshooting and problem-solving skills. Committed to safety and quality standards.

Education

Associate’s Degree or Diploma in Manufacturing or Mechanical Engineering

August 2018

Skills

- Deburring Machine Operation

- Deburring Process Optimization

- Laser Deburring

- Electrochemical Deburring

- Abrasive Flow Machining

- Cryogenic Deburring

Work Experience

Debridging Machine Operator

- Troubleshooted and repaired Debridging Machine malfunctions, minimizing downtime and maintaining production schedules.

- Collaborated with engineers to develop custom Debridging Machine tooling for intricate components, improving efficiency.

- Trained new operators on Debridging Machine operation and safety protocols, ensuring proper usage and compliance.

- Developed and implemented quality control procedures for Debridging Machine output, reducing defect rates by 10%.

Debridging Machine Operator

- Operated a Debridging Machine to remove sharp edges and corners from metal components, ensuring they met safety and quality standards.

- Utilized Debridging Machine to deburr and smooth castings, reducing production time by 20%.

- Set up and calibrated Debridging Machine to achieve precise edge removal, improving product quality by 15%.

- Optimized Debridging Machine settings to increase removal rate by 25%, reducing manufacturing costs.

Accomplishments

- Developed and implemented a new technique for deburring complex components, reducing cycle time by 10% while maintaining quality standards.

- Led a team in optimizing Debridging Machine settings, resulting in a 7% increase in production efficiency.

- Developed training materials and conducted workshops for new Debridging Machine Operators, improving team productivity.

- Collaborated with engineers to design and implement a custom Debridging Machine attachment, expanding the machines capabilities.

- Conducted preventive maintenance on Debridging Machine to ensure optimal operation and extend its lifespan.

Awards

- Recognized for exceptional performance in operating Debridging Machine, consistently exceeding production targets by 15%.

- Awarded the Machine Operator of the Year award for demonstrating exceptional skills and dedication in Debridging Machine operation.

- Received recognition for implementing a new safety protocol that significantly reduced workplace accidents.

- Honored with the Continuous Improvement Award for developing innovative solutions to enhance Debridging Machine performance.

Certificates

- Certified Deburring Technician (CDT)

- Certified Deburring Engineer (CDE)

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Debridging Machine Operator

- Highlight your technical skills and experience in operating and maintaining Debridging Machines.

- Showcase your ability to optimize processes and increase efficiency by providing quantifiable results.

- Emphasize your commitment to safety and quality by mentioning your adherence to industry standards and implementation of quality control procedures.

- Demonstrate your problem-solving abilities and proactive approach to troubleshooting and resolving issues.

- Tailor your resume to the specific requirements of the job posting, highlighting relevant skills and experience.

Essential Experience Highlights for a Strong Debridging Machine Operator Resume

- Operate and maintain Debridging Machines to remove sharp edges and corners from metal components, ensuring compliance with safety and quality standards.

- Set up and calibrate Debridging Machines to achieve precise edge removal, improving product quality and reducing defects.

- Optimize Debridging Machine settings to increase removal rate and efficiency, maximizing productivity and reducing manufacturing costs.

- Troubleshoot and repair Debridging Machine malfunctions, minimizing downtime and maintaining production schedules.

- Develop and implement quality control procedures for Debridging Machine output, reducing defect rates and ensuring product quality.

- Train new operators on Debridging Machine operation and safety protocols, fostering a skilled and competent workforce.

- Collaborate with engineers to develop custom Debridging Machine tooling for intricate components, enhancing efficiency and precision.

Frequently Asked Questions (FAQ’s) For Debridging Machine Operator

What is the role of a Debridging Machine Operator?

A Debridging Machine Operator is responsible for operating and maintaining Debridging Machines to remove sharp edges and corners from metal components, ensuring compliance with safety and quality standards.

What skills are required to be a successful Debridging Machine Operator?

Successful Debridging Machine Operators possess technical skills in operating and maintaining Debridging Machines, as well as process optimization, quality control, and troubleshooting.

What is the job market like for Debridging Machine Operators?

The job market for Debridging Machine Operators is expected to grow in the coming years due to the increasing demand for precision manufacturing and quality control in various industries.

What are the career prospects for Debridging Machine Operators?

Debridging Machine Operators with experience and expertise can advance to supervisory roles, quality control inspectors, or even management positions.

How can I improve my chances of getting hired as a Debridging Machine Operator?

To improve your chances of getting hired, focus on developing strong technical skills, gaining experience in operating and maintaining Debridging Machines, and obtaining relevant certifications or training.

What are the safety protocols that Debridging Machine Operators must follow?

Debridging Machine Operators must adhere to safety protocols such as wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What are the key performance indicators (KPIs) for Debridging Machine Operators?

KPIs for Debridging Machine Operators include production efficiency, quality of output, adherence to safety protocols, and overall equipment effectiveness (OEE).