Are you a seasoned Deburring and Tooling Machine Operator seeking a new career path? Discover our professionally built Deburring and Tooling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

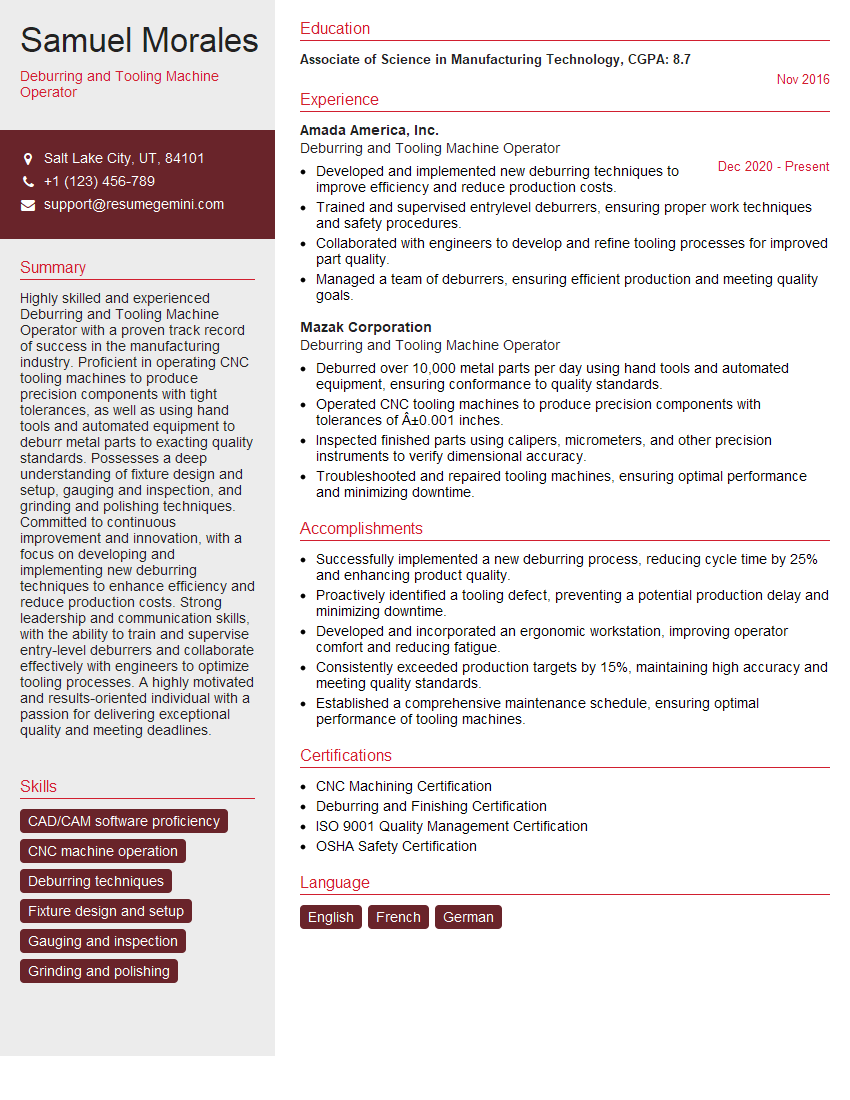

Samuel Morales

Deburring and Tooling Machine Operator

Summary

Highly skilled and experienced Deburring and Tooling Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating CNC tooling machines to produce precision components with tight tolerances, as well as using hand tools and automated equipment to deburr metal parts to exacting quality standards. Possesses a deep understanding of fixture design and setup, gauging and inspection, and grinding and polishing techniques. Committed to continuous improvement and innovation, with a focus on developing and implementing new deburring techniques to enhance efficiency and reduce production costs. Strong leadership and communication skills, with the ability to train and supervise entry-level deburrers and collaborate effectively with engineers to optimize tooling processes. A highly motivated and results-oriented individual with a passion for delivering exceptional quality and meeting deadlines.

Education

Associate of Science in Manufacturing Technology

November 2016

Skills

- CAD/CAM software proficiency

- CNC machine operation

- Deburring techniques

- Fixture design and setup

- Gauging and inspection

- Grinding and polishing

Work Experience

Deburring and Tooling Machine Operator

- Developed and implemented new deburring techniques to improve efficiency and reduce production costs.

- Trained and supervised entrylevel deburrers, ensuring proper work techniques and safety procedures.

- Collaborated with engineers to develop and refine tooling processes for improved part quality.

- Managed a team of deburrers, ensuring efficient production and meeting quality goals.

Deburring and Tooling Machine Operator

- Deburred over 10,000 metal parts per day using hand tools and automated equipment, ensuring conformance to quality standards.

- Operated CNC tooling machines to produce precision components with tolerances of ±0.001 inches.

- Inspected finished parts using calipers, micrometers, and other precision instruments to verify dimensional accuracy.

- Troubleshooted and repaired tooling machines, ensuring optimal performance and minimizing downtime.

Accomplishments

- Successfully implemented a new deburring process, reducing cycle time by 25% and enhancing product quality.

- Proactively identified a tooling defect, preventing a potential production delay and minimizing downtime.

- Developed and incorporated an ergonomic workstation, improving operator comfort and reducing fatigue.

- Consistently exceeded production targets by 15%, maintaining high accuracy and meeting quality standards.

- Established a comprehensive maintenance schedule, ensuring optimal performance of tooling machines.

Certificates

- CNC Machining Certification

- Deburring and Finishing Certification

- ISO 9001 Quality Management Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Deburring and Tooling Machine Operator

- Highlight your skills and experience in operating CNC tooling machines, as well as your proficiency in deburring techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Showcase your knowledge of fixture design and setup, gauging and inspection, and grinding and polishing.

- Emphasize your commitment to continuous improvement and innovation, and provide examples of how you have developed and implemented new deburring techniques.

- Highlight your leadership and communication skills, and provide examples of how you have trained and supervised entry-level deburrers and collaborated with engineers.

Essential Experience Highlights for a Strong Deburring and Tooling Machine Operator Resume

- Deburred over 10,000 metal parts per day using hand tools and automated equipment, ensuring conformance to quality standards.

- Operated CNC tooling machines to produce precision components with tolerances of ±0.001 inches.

- Inspected finished parts using calipers, micrometers, and other precision instruments to verify dimensional accuracy.

- Troubleshooted and repaired tooling machines, ensuring optimal performance and minimizing downtime.

- Developed and implemented new deburring techniques to improve efficiency and reduce production costs.

- Trained and supervised entry-level deburrers, ensuring proper work techniques and safety procedures.

- Collaborated with engineers to develop and refine tooling processes for improved part quality.

Frequently Asked Questions (FAQ’s) For Deburring and Tooling Machine Operator

What are the key skills required for a Deburring and Tooling Machine Operator?

The key skills required for a Deburring and Tooling Machine Operator include proficiency in operating CNC tooling machines, deburring techniques, fixture design and setup, gauging and inspection, and grinding and polishing.

What is the typical work environment for a Deburring and Tooling Machine Operator?

Deburring and Tooling Machine Operators typically work in manufacturing environments, operating machinery to deburr and finish metal parts. They may work independently or as part of a team, and may be responsible for setting up and maintaining their own equipment.

What are the career advancement opportunities for a Deburring and Tooling Machine Operator?

Deburring and Tooling Machine Operators may advance to positions such as CNC Programmer, Tool and Die Maker, or Manufacturing Engineer. With additional training and experience, they may also move into management roles.

What are the salary expectations for a Deburring and Tooling Machine Operator?

The salary expectations for a Deburring and Tooling Machine Operator vary depending on experience, location, and company size. According to Indeed, the average salary for a Deburring and Tooling Machine Operator in the United States is $20.50 per hour.

What are the job outlook prospects for a Deburring and Tooling Machine Operator?

The job outlook for Deburring and Tooling Machine Operators is expected to be good over the next few years. As manufacturing continues to grow, there will be a need for skilled workers to operate and maintain machinery.

What are the educational requirements for a Deburring and Tooling Machine Operator?

Most Deburring and Tooling Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

What are the physical demands of a Deburring and Tooling Machine Operator?

Deburring and Tooling Machine Operators must be able to stand for long periods of time and lift heavy objects. They may also be required to work in noisy and dusty environments.