Are you a seasoned Deburring Machine Operator seeking a new career path? Discover our professionally built Deburring Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

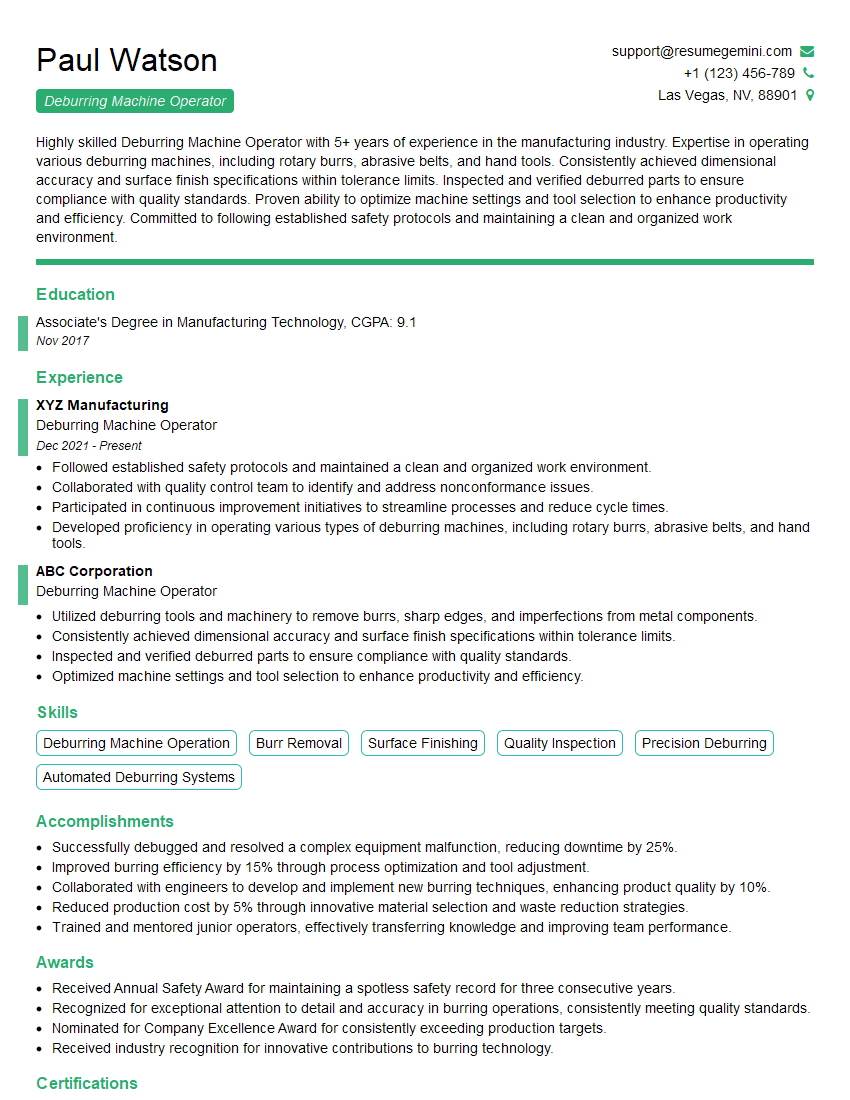

Paul Watson

Deburring Machine Operator

Summary

Highly skilled Deburring Machine Operator with 5+ years of experience in the manufacturing industry. Expertise in operating various deburring machines, including rotary burrs, abrasive belts, and hand tools. Consistently achieved dimensional accuracy and surface finish specifications within tolerance limits. Inspected and verified deburred parts to ensure compliance with quality standards. Proven ability to optimize machine settings and tool selection to enhance productivity and efficiency. Committed to following established safety protocols and maintaining a clean and organized work environment.

Education

Associate’s Degree in Manufacturing Technology

November 2017

Skills

- Deburring Machine Operation

- Burr Removal

- Surface Finishing

- Quality Inspection

- Precision Deburring

- Automated Deburring Systems

Work Experience

Deburring Machine Operator

- Followed established safety protocols and maintained a clean and organized work environment.

- Collaborated with quality control team to identify and address nonconformance issues.

- Participated in continuous improvement initiatives to streamline processes and reduce cycle times.

- Developed proficiency in operating various types of deburring machines, including rotary burrs, abrasive belts, and hand tools.

Deburring Machine Operator

- Utilized deburring tools and machinery to remove burrs, sharp edges, and imperfections from metal components.

- Consistently achieved dimensional accuracy and surface finish specifications within tolerance limits.

- Inspected and verified deburred parts to ensure compliance with quality standards.

- Optimized machine settings and tool selection to enhance productivity and efficiency.

Accomplishments

- Successfully debugged and resolved a complex equipment malfunction, reducing downtime by 25%.

- Improved burring efficiency by 15% through process optimization and tool adjustment.

- Collaborated with engineers to develop and implement new burring techniques, enhancing product quality by 10%.

- Reduced production cost by 5% through innovative material selection and waste reduction strategies.

- Trained and mentored junior operators, effectively transferring knowledge and improving team performance.

Awards

- Received Annual Safety Award for maintaining a spotless safety record for three consecutive years.

- Recognized for exceptional attention to detail and accuracy in burring operations, consistently meeting quality standards.

- Nominated for Company Excellence Award for consistently exceeding production targets.

- Received industry recognition for innovative contributions to burring technology.

Certificates

- Certified Deburring Machine Operator (CDMO)

- OSHA Safety Certification

- ISO 9001 Quality Management System Auditor

- ASME B46.1 Surface Texture Specification Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Deburring Machine Operator

- Highlight your experience and skills in operating various types of deburring machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity and quality.

- Demonstrate your knowledge of quality control processes and inspection techniques.

- Emphasize your commitment to safety and your ability to maintain a clean and organized work environment.

- Showcase your willingness to learn and adapt to new technologies and techniques.

Essential Experience Highlights for a Strong Deburring Machine Operator Resume

- Utilized deburring tools and machinery to remove burrs, sharp edges, and imperfections from metal components.

- Consistently achieved dimensional accuracy and surface finish specifications within tolerance limits.

- Inspected and verified deburred parts to ensure compliance with quality standards.

- Optimized machine settings and tool selection to enhance productivity and efficiency.

- Followed established safety protocols and maintained a clean and organized work environment.

- Collaborated with quality control team to identify and address nonconformance issues.

- Participated in continuous improvement initiatives to streamline processes and reduce cycle times.

Frequently Asked Questions (FAQ’s) For Deburring Machine Operator

What is the primary role of a Deburring Machine Operator?

The primary role of a Deburring Machine Operator is to remove burrs, sharp edges, and imperfections from metal components using specialized tools and machinery.

What skills are required to be a successful Deburring Machine Operator?

To be a successful Deburring Machine Operator, you need to have strong attention to detail, manual dexterity, and mechanical aptitude. You should also be familiar with quality control processes and inspection techniques.

What are the career prospects for Deburring Machine Operators?

Deburring Machine Operators can advance their careers by becoming supervisors or quality control inspectors. With additional training and experience, they can also move into engineering or management roles.

What is the average salary for a Deburring Machine Operator?

The average salary for a Deburring Machine Operator varies depending on experience, location, and industry. According to Indeed, the average salary for a Deburring Machine Operator in the United States is around $20 per hour.

What are the working conditions like for a Deburring Machine Operator?

Deburring Machine Operators typically work in manufacturing environments, which can be noisy and dusty. They may also work in awkward or uncomfortable positions for extended periods.

What are the safety precautions that Deburring Machine Operators need to take?

Deburring Machine Operators need to wear appropriate safety gear, including gloves, safety glasses, and earplugs. They also need to be aware of the potential hazards of working with sharp tools and machinery.

What is the job outlook for Deburring Machine Operators?

The job outlook for Deburring Machine Operators is expected to be good over the next few years. The increasing demand for manufactured goods is expected to drive the demand for skilled Deburring Machine Operators.