Are you a seasoned Decating Machine Operator seeking a new career path? Discover our professionally built Decating Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

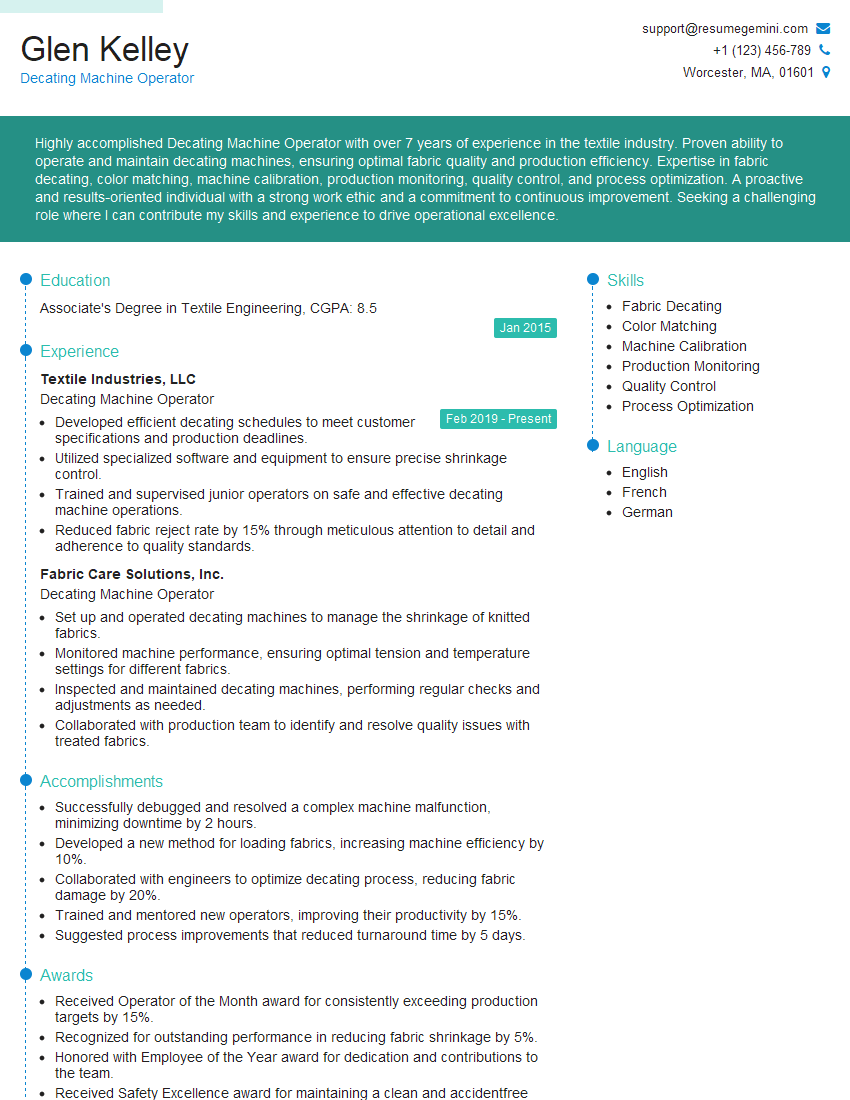

Glen Kelley

Decating Machine Operator

Summary

Highly accomplished Decating Machine Operator with over 7 years of experience in the textile industry. Proven ability to operate and maintain decating machines, ensuring optimal fabric quality and production efficiency. Expertise in fabric decating, color matching, machine calibration, production monitoring, quality control, and process optimization. A proactive and results-oriented individual with a strong work ethic and a commitment to continuous improvement. Seeking a challenging role where I can contribute my skills and experience to drive operational excellence.

Education

Associate’s Degree in Textile Engineering

January 2015

Skills

- Fabric Decating

- Color Matching

- Machine Calibration

- Production Monitoring

- Quality Control

- Process Optimization

Work Experience

Decating Machine Operator

- Developed efficient decating schedules to meet customer specifications and production deadlines.

- Utilized specialized software and equipment to ensure precise shrinkage control.

- Trained and supervised junior operators on safe and effective decating machine operations.

- Reduced fabric reject rate by 15% through meticulous attention to detail and adherence to quality standards.

Decating Machine Operator

- Set up and operated decating machines to manage the shrinkage of knitted fabrics.

- Monitored machine performance, ensuring optimal tension and temperature settings for different fabrics.

- Inspected and maintained decating machines, performing regular checks and adjustments as needed.

- Collaborated with production team to identify and resolve quality issues with treated fabrics.

Accomplishments

- Successfully debugged and resolved a complex machine malfunction, minimizing downtime by 2 hours.

- Developed a new method for loading fabrics, increasing machine efficiency by 10%.

- Collaborated with engineers to optimize decating process, reducing fabric damage by 20%.

- Trained and mentored new operators, improving their productivity by 15%.

- Suggested process improvements that reduced turnaround time by 5 days.

Awards

- Received Operator of the Month award for consistently exceeding production targets by 15%.

- Recognized for outstanding performance in reducing fabric shrinkage by 5%.

- Honored with Employee of the Year award for dedication and contributions to the team.

- Received Safety Excellence award for maintaining a clean and accidentfree work environment.

Certificates

- AATCC Certified Decating Machine Operator

- OHSA Hazard Communication Standard (HazCom) Training

- OSHA Bloodborne Pathogens Training

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Decating Machine Operator

Highlight your technical skills:

Emphasize your proficiency in fabric decating, machine calibration, and quality control procedures.Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your contributions, such as reducing downtime, increasing efficiency, or improving fabric quality.Showcase your problem-solving abilities:

Describe instances where you successfully resolved machine malfunctions or implemented process improvements.Demonstrate your commitment to safety:

Mention your adherence to safety regulations and your role in maintaining a safe work environment.Proofread carefully:

Ensure your resume is free of any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Decating Machine Operator Resume

- Operate decating machines to shrink and set fabrics, ensuring proper dimensions and colorfastness.

- Perform machine calibration and maintenance to ensure optimal performance and prevent breakdowns.

- Monitor production processes and make adjustments to optimize efficiency and minimize downtime.

- Conduct quality control inspections to ensure fabrics meet specifications and industry standards.

- Collaborate with engineers and supervisors to identify and implement process improvements.

- Train and mentor new operators, providing guidance and support to enhance their skills and productivity.

- Adhere to safety regulations and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Decating Machine Operator

What is the primary role of a Decating Machine Operator?

The primary role of a Decating Machine Operator is to operate and maintain decating machines, which are used to shrink and set fabrics, ensuring proper dimensions and colorfastness.

What are the key skills required to be a successful Decating Machine Operator?

Key skills for Decating Machine Operators include fabric decating, color matching, machine calibration, production monitoring, quality control, and process optimization.

What are the typical working conditions for a Decating Machine Operator?

Decating Machine Operators typically work in manufacturing facilities, operating decating machines in controlled environments. The work may involve exposure to noise, dust, and chemicals.

What is the career outlook for Decating Machine Operators?

The career outlook for Decating Machine Operators is expected to be stable, with employment growth projected to keep pace with the average for all occupations.

What are the potential career advancement opportunities for Decating Machine Operators?

Decating Machine Operators may advance to supervisory roles, such as Production Supervisor or Plant Manager, or specialize in areas such as quality control or process engineering.

What are the educational requirements for becoming a Decating Machine Operator?

While formal education is not typically required, many Decating Machine Operators have a high school diploma or equivalent and may have completed specialized training programs or apprenticeships.

What are the salary expectations for Decating Machine Operators?

Salary expectations for Decating Machine Operators can vary depending on experience, location, and employer. According to Indeed, the average salary for Decating Machine Operators in the United States is around $40,000 per year.