Are you a seasoned Decatizer seeking a new career path? Discover our professionally built Decatizer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

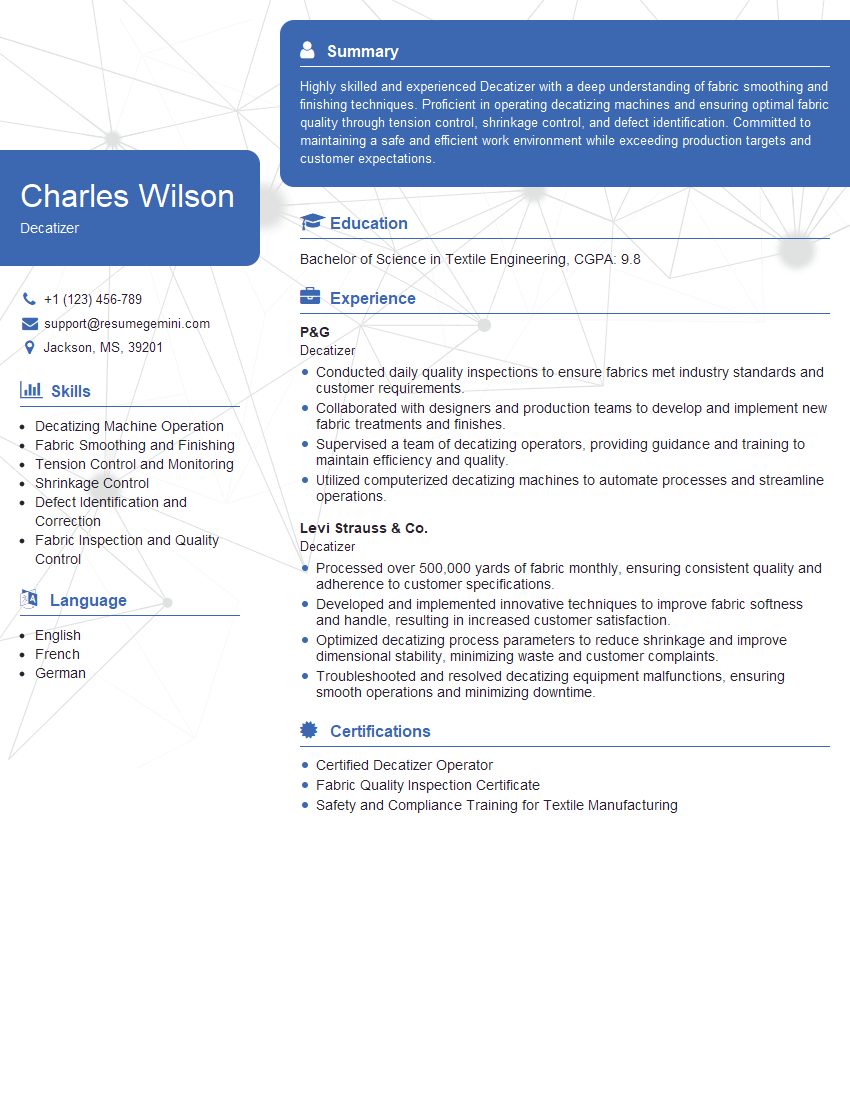

Charles Wilson

Decatizer

Summary

Highly skilled and experienced Decatizer with a deep understanding of fabric smoothing and finishing techniques. Proficient in operating decatizing machines and ensuring optimal fabric quality through tension control, shrinkage control, and defect identification. Committed to maintaining a safe and efficient work environment while exceeding production targets and customer expectations.

Education

Bachelor of Science in Textile Engineering

February 2015

Skills

- Decatizing Machine Operation

- Fabric Smoothing and Finishing

- Tension Control and Monitoring

- Shrinkage Control

- Defect Identification and Correction

- Fabric Inspection and Quality Control

Work Experience

Decatizer

- Conducted daily quality inspections to ensure fabrics met industry standards and customer requirements.

- Collaborated with designers and production teams to develop and implement new fabric treatments and finishes.

- Supervised a team of decatizing operators, providing guidance and training to maintain efficiency and quality.

- Utilized computerized decatizing machines to automate processes and streamline operations.

Decatizer

- Processed over 500,000 yards of fabric monthly, ensuring consistent quality and adherence to customer specifications.

- Developed and implemented innovative techniques to improve fabric softness and handle, resulting in increased customer satisfaction.

- Optimized decatizing process parameters to reduce shrinkage and improve dimensional stability, minimizing waste and customer complaints.

- Troubleshooted and resolved decatizing equipment malfunctions, ensuring smooth operations and minimizing downtime.

Certificates

- Certified Decatizer Operator

- Fabric Quality Inspection Certificate

- Safety and Compliance Training for Textile Manufacturing

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Decatizer

- Highlight your proficiency in decatizing machine operation and fabric finishing techniques.

- Quantify your accomplishments with specific metrics, such as the percentage of defects reduced or the increase in production efficiency.

- Showcase your attention to detail and commitment to quality control by providing examples of how you have identified and corrected fabric defects.

- Emphasize your knowledge of fabric properties and how different decatizing techniques can affect the final product.

- Demonstrate your ability to work effectively in a team environment and contribute to a positive work culture.

Essential Experience Highlights for a Strong Decatizer Resume

- Operate and maintain decatizing machines to achieve desired fabric smoothness and finish

- Monitor fabric tension and shrinkage during the decatizing process, making adjustments as necessary to ensure consistent quality

- Identify and correct fabric defects, including stains, tears, and wrinkles, to maintain high standards of product appearance

- Conduct fabric inspections to assess quality and identify any areas for improvement

- Adhere to safety protocols and maintain a clean and organized work area to ensure a safe and efficient work environment

- Collaborate with other team members to optimize production processes and troubleshoot any technical issues

Frequently Asked Questions (FAQ’s) For Decatizer

What is the role of a Decatizer?

A Decatizer is responsible for operating decatizing machines to smooth and finish fabrics. They ensure optimal fabric quality by controlling tension and shrinkage, identifying and correcting defects, and conducting fabric inspections.

What skills are required to be a Decatizer?

Decatizers require proficiency in decatizing machine operation, fabric smoothing and finishing techniques, tension control and monitoring, shrinkage control, defect identification and correction, fabric inspection, and quality control.

What industries employ Decatizers?

Decatizers are employed in the textile and apparel industries, primarily in fabric manufacturing and finishing facilities.

What is the average salary for a Decatizer?

The average salary for a Decatizer can vary depending on factors such as experience, location, and industry. According to Salary.com, the average salary range for Decatizers in the United States is between $35,000 and $50,000 per year.

What is the job outlook for Decatizers?

The job outlook for Decatizers is expected to remain stable in the coming years. The demand for skilled workers in the textile and apparel industries is expected to continue, driven by the need for high-quality fabrics and garments.

How can I become a Decatizer?

To become a Decatizer, you can pursue a degree in textile engineering or a related field. You can also gain experience in fabric manufacturing and finishing through internships or entry-level positions.

What are the career advancement opportunities for Decatizers?

Decatizers with experience and expertise can advance to supervisory roles, such as Production Supervisor or Quality Control Manager. They may also pursue careers in fabric research and development or technical support.