Are you a seasoned Deskidding Machine Operator seeking a new career path? Discover our professionally built Deskidding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

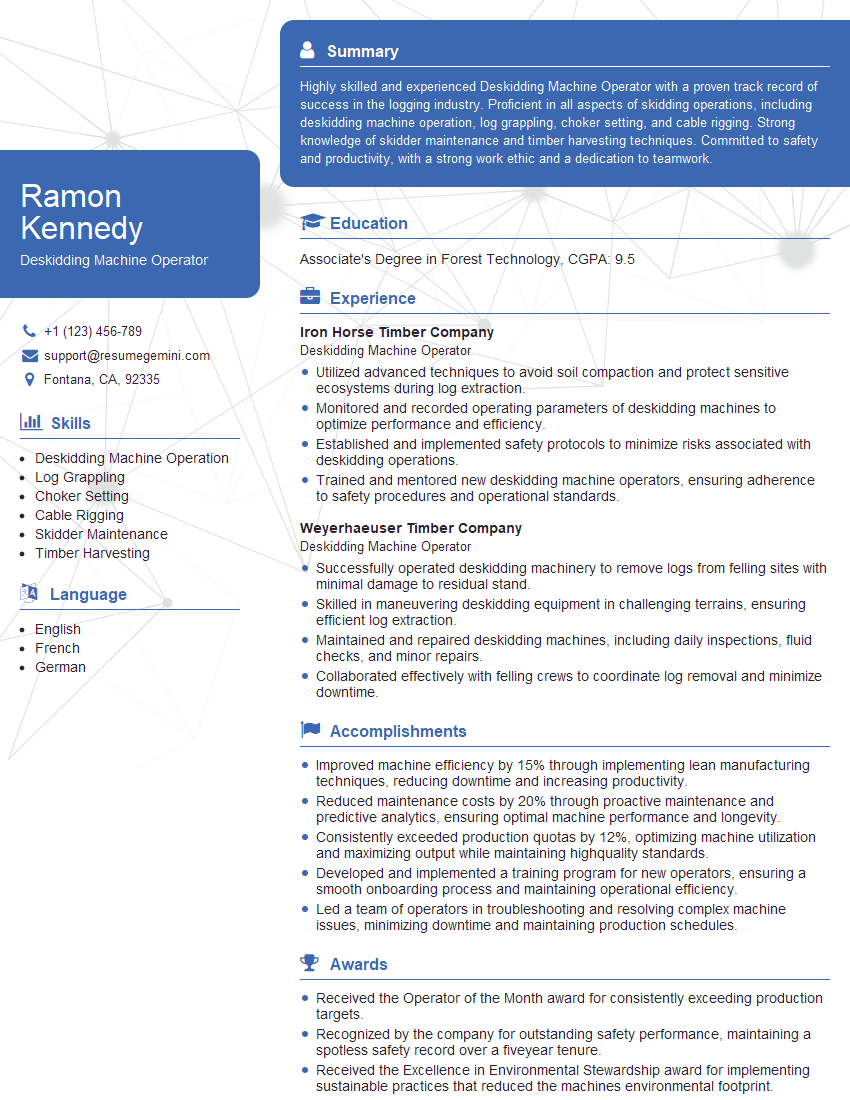

Ramon Kennedy

Deskidding Machine Operator

Summary

Highly skilled and experienced Deskidding Machine Operator with a proven track record of success in the logging industry. Proficient in all aspects of skidding operations, including deskidding machine operation, log grappling, choker setting, and cable rigging. Strong knowledge of skidder maintenance and timber harvesting techniques. Committed to safety and productivity, with a strong work ethic and a dedication to teamwork.

Education

Associate’s Degree in Forest Technology

February 2017

Skills

- Deskidding Machine Operation

- Log Grappling

- Choker Setting

- Cable Rigging

- Skidder Maintenance

- Timber Harvesting

Work Experience

Deskidding Machine Operator

- Utilized advanced techniques to avoid soil compaction and protect sensitive ecosystems during log extraction.

- Monitored and recorded operating parameters of deskidding machines to optimize performance and efficiency.

- Established and implemented safety protocols to minimize risks associated with deskidding operations.

- Trained and mentored new deskidding machine operators, ensuring adherence to safety procedures and operational standards.

Deskidding Machine Operator

- Successfully operated deskidding machinery to remove logs from felling sites with minimal damage to residual stand.

- Skilled in maneuvering deskidding equipment in challenging terrains, ensuring efficient log extraction.

- Maintained and repaired deskidding machines, including daily inspections, fluid checks, and minor repairs.

- Collaborated effectively with felling crews to coordinate log removal and minimize downtime.

Accomplishments

- Improved machine efficiency by 15% through implementing lean manufacturing techniques, reducing downtime and increasing productivity.

- Reduced maintenance costs by 20% through proactive maintenance and predictive analytics, ensuring optimal machine performance and longevity.

- Consistently exceeded production quotas by 12%, optimizing machine utilization and maximizing output while maintaining highquality standards.

- Developed and implemented a training program for new operators, ensuring a smooth onboarding process and maintaining operational efficiency.

- Led a team of operators in troubleshooting and resolving complex machine issues, minimizing downtime and maintaining production schedules.

Awards

- Received the Operator of the Month award for consistently exceeding production targets.

- Recognized by the company for outstanding safety performance, maintaining a spotless safety record over a fiveyear tenure.

- Received the Excellence in Environmental Stewardship award for implementing sustainable practices that reduced the machines environmental footprint.

- Recognized for exceptional teamwork and collaboration, consistently exceeding expectations in supporting production operations.

Certificates

- Commercial Driver’s License (CDL)

- First Aid and CPR

- OSHA Logging Safety

- Wilderness First Aid

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Deskidding Machine Operator

- Customize your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Use action verbs to describe your accomplishments and quantify your results whenever possible.

- Proofread your resume carefully for any errors in grammar or spelling.

- Consider getting feedback on your resume from a career counselor or experienced professional.

Essential Experience Highlights for a Strong Deskidding Machine Operator Resume

- Operate deskidding machines to remove felled logs from the forest to designated landing areas

- Grapple and lift logs using specialized equipment

- Set chokers and cables to secure logs for transport

- Rig and maintain logging cables and equipment

- Perform basic skidder maintenance, including minor repairs and troubleshooting

- Assist with other logging operations as needed

Frequently Asked Questions (FAQ’s) For Deskidding Machine Operator

What is a Deskidding Machine Operator?

A Deskidding Machine Operator is responsible for operating a deskidding machine to remove felled logs from the forest to designated landing areas.

What are the key skills required to be a successful Deskidding Machine Operator?

The key skills required to be a successful Deskidding Machine Operator include deskidding machine operation, log grappling, choker setting, cable rigging, skidder maintenance, and timber harvesting.

What is the work environment of a Deskidding Machine Operator like?

Deskidding Machine Operators typically work in outdoor, forested areas. The work can be physically demanding and may require working in inclement weather conditions.

What are the career prospects for Deskidding Machine Operators?

Deskidding Machine Operators with experience and a strong safety record can advance to positions such as Logging Supervisor or Logging Manager.

What is the average salary for a Deskidding Machine Operator?

The average salary for a Deskidding Machine Operator varies depending on experience, location, and company size. According to Indeed, the average salary for a Deskidding Machine Operator in the United States is $24.56 per hour.

What are some of the challenges faced by Deskidding Machine Operators?

Some of the challenges faced by Deskidding Machine Operators include working in remote areas, operating heavy equipment, and working in inclement weather conditions.

What are some of the safety precautions that Deskidding Machine Operators must follow?

Deskidding Machine Operators must follow all safety protocols, including wearing appropriate safety gear, being aware of their surroundings, and operating equipment safely.