Are you a seasoned Die Casting Supervisor seeking a new career path? Discover our professionally built Die Casting Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

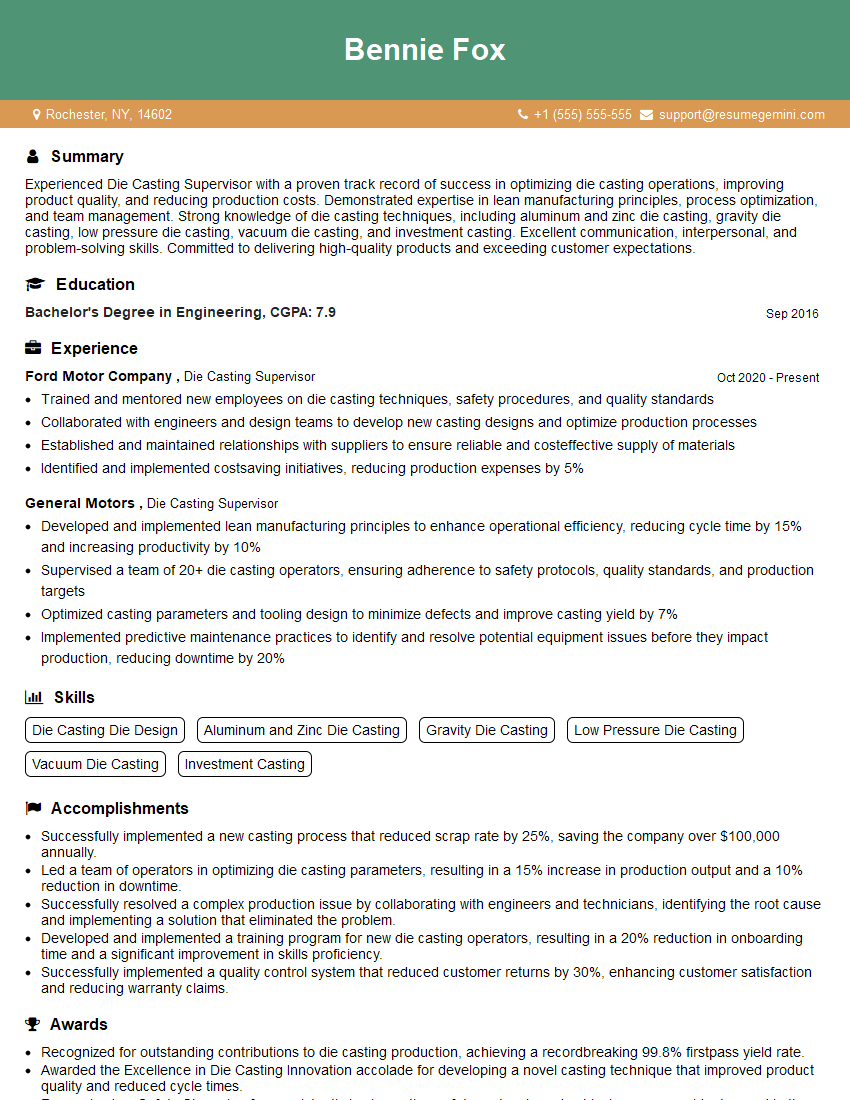

Bennie Fox

Die Casting Supervisor

Summary

Experienced Die Casting Supervisor with a proven track record of success in optimizing die casting operations, improving product quality, and reducing production costs. Demonstrated expertise in lean manufacturing principles, process optimization, and team management. Strong knowledge of die casting techniques, including aluminum and zinc die casting, gravity die casting, low pressure die casting, vacuum die casting, and investment casting. Excellent communication, interpersonal, and problem-solving skills. Committed to delivering high-quality products and exceeding customer expectations.

Education

Bachelor’s Degree in Engineering

September 2016

Skills

- Die Casting Die Design

- Aluminum and Zinc Die Casting

- Gravity Die Casting

- Low Pressure Die Casting

- Vacuum Die Casting

- Investment Casting

Work Experience

Die Casting Supervisor

- Trained and mentored new employees on die casting techniques, safety procedures, and quality standards

- Collaborated with engineers and design teams to develop new casting designs and optimize production processes

- Established and maintained relationships with suppliers to ensure reliable and costeffective supply of materials

- Identified and implemented costsaving initiatives, reducing production expenses by 5%

Die Casting Supervisor

- Developed and implemented lean manufacturing principles to enhance operational efficiency, reducing cycle time by 15% and increasing productivity by 10%

- Supervised a team of 20+ die casting operators, ensuring adherence to safety protocols, quality standards, and production targets

- Optimized casting parameters and tooling design to minimize defects and improve casting yield by 7%

- Implemented predictive maintenance practices to identify and resolve potential equipment issues before they impact production, reducing downtime by 20%

Accomplishments

- Successfully implemented a new casting process that reduced scrap rate by 25%, saving the company over $100,000 annually.

- Led a team of operators in optimizing die casting parameters, resulting in a 15% increase in production output and a 10% reduction in downtime.

- Successfully resolved a complex production issue by collaborating with engineers and technicians, identifying the root cause and implementing a solution that eliminated the problem.

- Developed and implemented a training program for new die casting operators, resulting in a 20% reduction in onboarding time and a significant improvement in skills proficiency.

- Successfully implemented a quality control system that reduced customer returns by 30%, enhancing customer satisfaction and reducing warranty claims.

Awards

- Recognized for outstanding contributions to die casting production, achieving a recordbreaking 99.8% firstpass yield rate.

- Awarded the Excellence in Die Casting Innovation accolade for developing a novel casting technique that improved product quality and reduced cycle times.

- Recognized as Safety Champion for consistently implementing safety protocols and achieving a zeroaccident record in the die casting department.

- Awarded the Employee of the Quarter distinction for exceptional performance in managing the die casting operation and exceeding production targets.

Certificates

- Certified Die Casting Supervisor (CDCS)

- Certified Die Casting Process Engineer (CDPE)

- Certified Metallographer (CMet)

- Certified Quality Auditor (CQA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Casting Supervisor

- Highlight your experience in implementing lean manufacturing principles and quantifying the results.

- Showcase your expertise in die casting techniques and process optimization.

- Demonstrate your ability to manage a team and achieve production targets.

- Emphasize your commitment to safety, quality, and customer satisfaction.

Essential Experience Highlights for a Strong Die Casting Supervisor Resume

- Supervise a team of die casting operators, ensuring adherence to safety protocols, quality standards, and production targets.

- Optimize casting parameters and tooling design to minimize defects and improve casting yield.

- Implement predictive maintenance practices to identify and resolve potential equipment issues before they impact production.

- Train and mentor new employees on die casting techniques, safety procedures, and quality standards.

- Collaborate with engineers and design teams to develop new casting designs and optimize production processes.

- Establish and maintain relationships with suppliers to ensure reliable and cost-effective supply of materials.

- Identify and implement cost-saving initiatives to reduce production expenses.

Frequently Asked Questions (FAQ’s) For Die Casting Supervisor

What are the key skills and qualifications required to be a successful Die Casting Supervisor?

Die Casting Supervisors should have a strong understanding of die casting techniques, including aluminum and zinc die casting, gravity die casting, low pressure die casting, vacuum die casting, and investment casting. They should also be proficient in lean manufacturing principles, process optimization, and team management. Excellent communication, interpersonal, and problem-solving skills are also essential.

What are the primary responsibilities of a Die Casting Supervisor?

Die Casting Supervisors are responsible for supervising a team of die casting operators, optimizing casting parameters and tooling design, implementing predictive maintenance practices, training and mentoring new employees, collaborating with engineers and design teams, establishing and maintaining relationships with suppliers, and identifying and implementing cost-saving initiatives.

What are the career advancement opportunities for Die Casting Supervisors?

Die Casting Supervisors with experience and a proven track record of success can advance to roles such as Die Casting Manager, Production Manager, or Plant Manager.

What are the typical salary expectations for Die Casting Supervisors?

The salary expectations for Die Casting Supervisors vary depending on experience, qualifications, and location. According to Indeed, the average salary for Die Casting Supervisors in the United States is around $65,000 per year.

What are the challenges faced by Die Casting Supervisors?

Die Casting Supervisors may face challenges such as meeting production targets, maintaining quality standards, managing a team, and implementing new technologies. They may also need to address issues such as equipment downtime, material shortages, and customer complaints.

How can I prepare for an interview for a Die Casting Supervisor position?

To prepare for an interview for a Die Casting Supervisor position, you should review the job description carefully and research the company. You should also practice answering common interview questions, such as those related to your experience, skills, and qualifications. It is also helpful to have examples of your work, such as process improvement projects or cost-saving initiatives, to share with the interviewer.

What are the key trends in the Die Casting industry?

Key trends in the Die Casting industry include the adoption of lean manufacturing principles, the use of new materials and technologies, and the increasing demand for lightweight and durable components.