Are you a seasoned Die Fitter seeking a new career path? Discover our professionally built Die Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

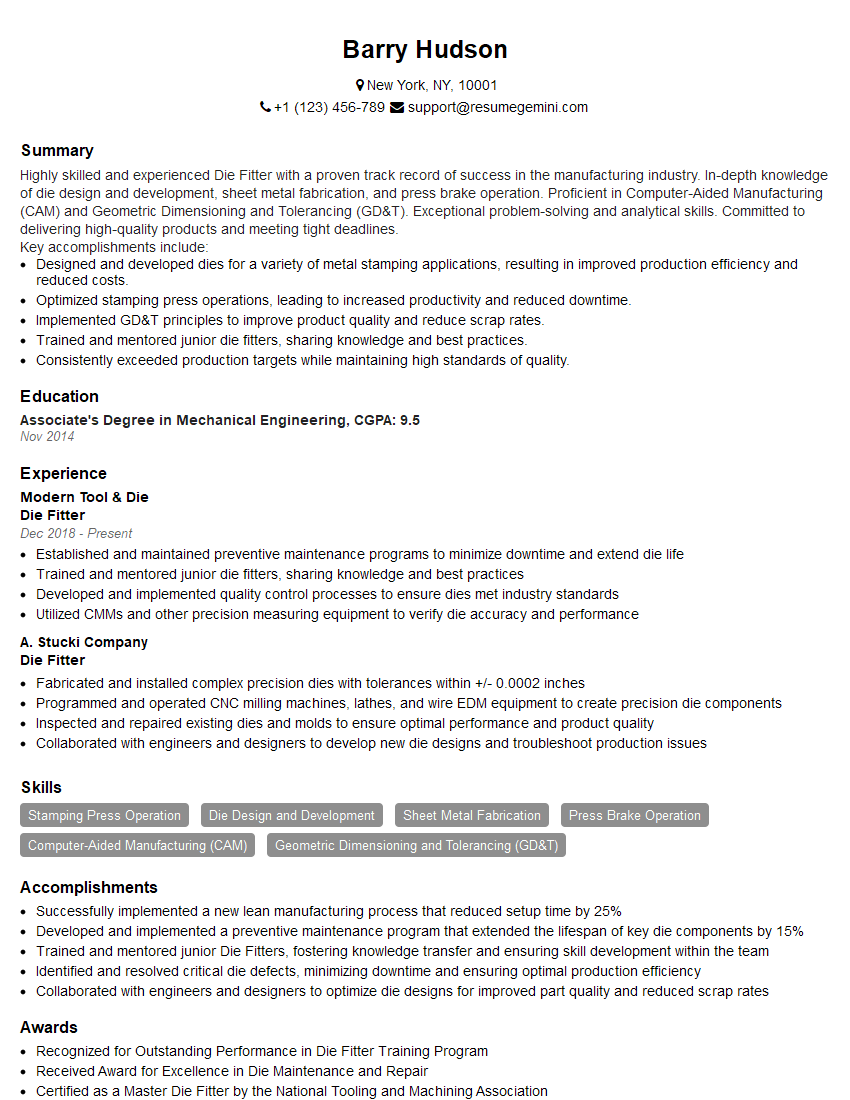

Barry Hudson

Die Fitter

Summary

Highly skilled and experienced Die Fitter with a proven track record of success in the manufacturing industry. In-depth knowledge of die design and development, sheet metal fabrication, and press brake operation. Proficient in Computer-Aided Manufacturing (CAM) and Geometric Dimensioning and Tolerancing (GD&T). Exceptional problem-solving and analytical skills. Committed to delivering high-quality products and meeting tight deadlines.

Key accomplishments include:

- Designed and developed dies for a variety of metal stamping applications, resulting in improved production efficiency and reduced costs.

- Optimized stamping press operations, leading to increased productivity and reduced downtime.

- Implemented GD&T principles to improve product quality and reduce scrap rates.

- Trained and mentored junior die fitters, sharing knowledge and best practices.

- Consistently exceeded production targets while maintaining high standards of quality.

Education

Associate’s Degree in Mechanical Engineering

November 2014

Skills

- Stamping Press Operation

- Die Design and Development

- Sheet Metal Fabrication

- Press Brake Operation

- Computer-Aided Manufacturing (CAM)

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Die Fitter

- Established and maintained preventive maintenance programs to minimize downtime and extend die life

- Trained and mentored junior die fitters, sharing knowledge and best practices

- Developed and implemented quality control processes to ensure dies met industry standards

- Utilized CMMs and other precision measuring equipment to verify die accuracy and performance

Die Fitter

- Fabricated and installed complex precision dies with tolerances within +/- 0.0002 inches

- Programmed and operated CNC milling machines, lathes, and wire EDM equipment to create precision die components

- Inspected and repaired existing dies and molds to ensure optimal performance and product quality

- Collaborated with engineers and designers to develop new die designs and troubleshoot production issues

Accomplishments

- Successfully implemented a new lean manufacturing process that reduced setup time by 25%

- Developed and implemented a preventive maintenance program that extended the lifespan of key die components by 15%

- Trained and mentored junior Die Fitters, fostering knowledge transfer and ensuring skill development within the team

- Identified and resolved critical die defects, minimizing downtime and ensuring optimal production efficiency

- Collaborated with engineers and designers to optimize die designs for improved part quality and reduced scrap rates

Awards

- Recognized for Outstanding Performance in Die Fitter Training Program

- Received Award for Excellence in Die Maintenance and Repair

- Certified as a Master Die Fitter by the National Tooling and Machining Association

Certificates

- Certified Die Fitter (CDF)

- Stamping Safety Certification

- ISO 9001:2015 Quality Management System Auditor

- OSHA 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Fitter

- Quantify your accomplishments using specific metrics to demonstrate your impact.

- Highlight your proficiency in CAD/CAM software and GD&T principles.

- Emphasize your ability to troubleshoot and resolve production issues efficiently.

- Include relevant certifications and training programs to showcase your commitment to professional development.

Essential Experience Highlights for a Strong Die Fitter Resume

- Design and develop dies for metal stamping applications, ensuring accuracy and precision.

- Set up and operate stamping presses, optimizing production efficiency.

- Inspect and maintain dies, identifying and resolving any issues.

- Interpret engineering drawings and specifications, ensuring adherence to design requirements.

- Troubleshoot and resolve production problems related to die performance.

- Collaborate with engineers and quality control personnel to improve product quality and reduce costs.

- Train and supervise junior die fitters, providing guidance and support.

Frequently Asked Questions (FAQ’s) For Die Fitter

What is the role of a Die Fitter?

A Die Fitter is responsible for designing, developing, and maintaining dies used in metal stamping operations. They ensure that dies meet engineering specifications, optimize production efficiency, and troubleshoot any issues that arise during the stamping process.

What skills are required to be a successful Die Fitter?

Successful Die Fitters possess strong mechanical aptitude, proficiency in CAD/CAM software, knowledge of GD&T principles, and excellent problem-solving and analytical skills. They are also skilled in operating and maintaining stamping presses.

What are the career prospects for Die Fitters?

Die Fitters with the right skills and experience can advance to supervisory roles, such as Die Fitter Lead or Die Fitter Manager. They may also specialize in particular areas of die design or fabrication.

What is the earning potential for Die Fitters?

The earning potential for Die Fitters varies depending on experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Tool and Die Makers, which includes Die Fitters, was $56,980 in May 2021.

What is the job outlook for Die Fitters?

The job outlook for Die Fitters is expected to be good over the next decade. The demand for skilled workers in the manufacturing industry is expected to increase as companies continue to invest in automation and efficiency.

What advice would you give to someone considering a career as a Die Fitter?

To succeed as a Die Fitter, it is important to develop a strong foundation in mechanical engineering principles, CAD/CAM software, and GD&T. Practical experience in a manufacturing environment is also valuable. Joining industry organizations and attending training programs can help you stay up-to-date on the latest technologies and best practices.