Are you a seasoned Die Mounter seeking a new career path? Discover our professionally built Die Mounter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

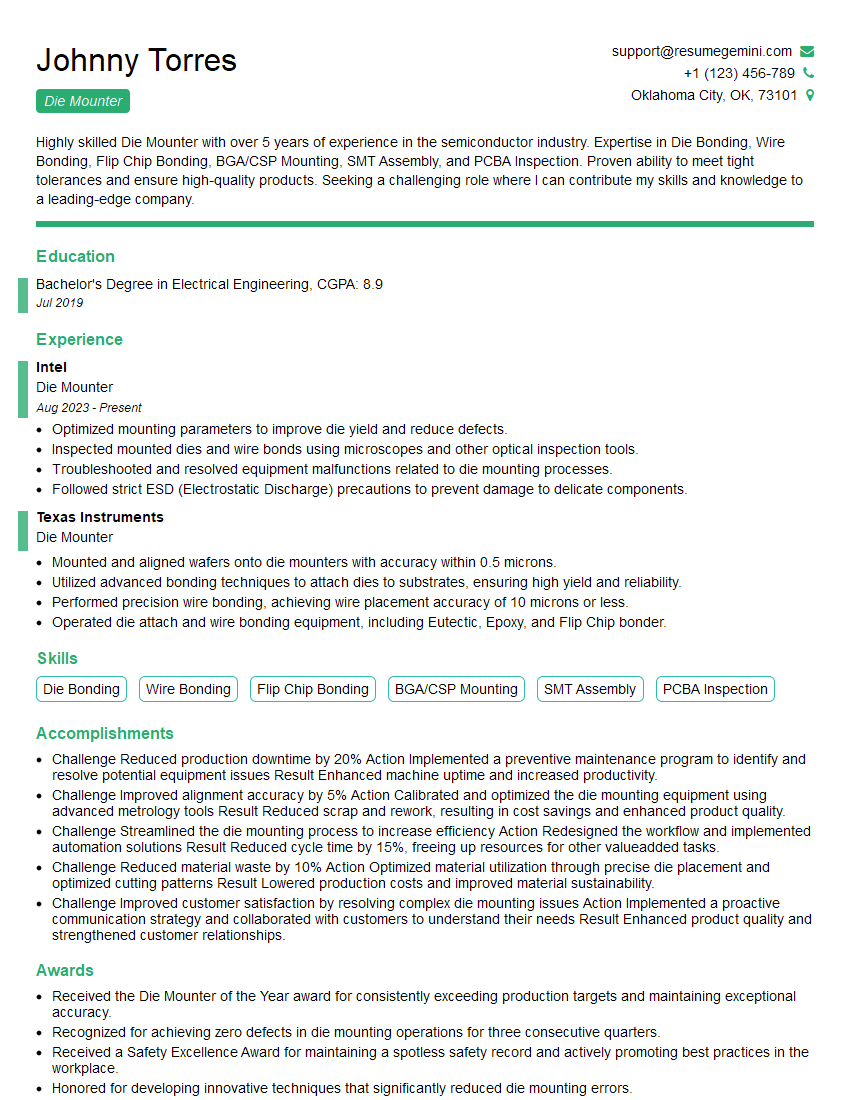

Johnny Torres

Die Mounter

Summary

Highly skilled Die Mounter with over 5 years of experience in the semiconductor industry. Expertise in Die Bonding, Wire Bonding, Flip Chip Bonding, BGA/CSP Mounting, SMT Assembly, and PCBA Inspection. Proven ability to meet tight tolerances and ensure high-quality products. Seeking a challenging role where I can contribute my skills and knowledge to a leading-edge company.

Education

Bachelor’s Degree in Electrical Engineering

July 2019

Skills

- Die Bonding

- Wire Bonding

- Flip Chip Bonding

- BGA/CSP Mounting

- SMT Assembly

- PCBA Inspection

Work Experience

Die Mounter

- Optimized mounting parameters to improve die yield and reduce defects.

- Inspected mounted dies and wire bonds using microscopes and other optical inspection tools.

- Troubleshooted and resolved equipment malfunctions related to die mounting processes.

- Followed strict ESD (Electrostatic Discharge) precautions to prevent damage to delicate components.

Die Mounter

- Mounted and aligned wafers onto die mounters with accuracy within 0.5 microns.

- Utilized advanced bonding techniques to attach dies to substrates, ensuring high yield and reliability.

- Performed precision wire bonding, achieving wire placement accuracy of 10 microns or less.

- Operated die attach and wire bonding equipment, including Eutectic, Epoxy, and Flip Chip bonder.

Accomplishments

- Challenge Reduced production downtime by 20% Action Implemented a preventive maintenance program to identify and resolve potential equipment issues Result Enhanced machine uptime and increased productivity.

- Challenge Improved alignment accuracy by 5% Action Calibrated and optimized the die mounting equipment using advanced metrology tools Result Reduced scrap and rework, resulting in cost savings and enhanced product quality.

- Challenge Streamlined the die mounting process to increase efficiency Action Redesigned the workflow and implemented automation solutions Result Reduced cycle time by 15%, freeing up resources for other valueadded tasks.

- Challenge Reduced material waste by 10% Action Optimized material utilization through precise die placement and optimized cutting patterns Result Lowered production costs and improved material sustainability.

- Challenge Improved customer satisfaction by resolving complex die mounting issues Action Implemented a proactive communication strategy and collaborated with customers to understand their needs Result Enhanced product quality and strengthened customer relationships.

Awards

- Received the Die Mounter of the Year award for consistently exceeding production targets and maintaining exceptional accuracy.

- Recognized for achieving zero defects in die mounting operations for three consecutive quarters.

- Received a Safety Excellence Award for maintaining a spotless safety record and actively promoting best practices in the workplace.

- Honored for developing innovative techniques that significantly reduced die mounting errors.

Certificates

- Certified IPC Specialist

- Certified Microelectronics Technician

- ASQ Certified Six Sigma Green Belt

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Die Mounter

- Highlight your technical skills and experience in Die Bonding, Wire Bonding, Flip Chip Bonding, BGA/CSP Mounting, SMT Assembly, and PCBA Inspection.

- Quantify your accomplishments with specific metrics, such as the number of dies mounted per hour or the percentage of defect-free products.

- Showcase your attention to detail and commitment to quality by emphasizing your ability to meet tight tolerances and ensure high-quality products.

- Demonstrate your knowledge of the latest industry trends and technologies, such as advanced packaging and assembly techniques.

Essential Experience Highlights for a Strong Die Mounter Resume

- Operated die bonding machines to precisely mount semiconductor dies onto substrates.

- Performed wire bonding, flip chip bonding, BGA/CSP mounting, and SMT assembly to connect dies to substrates and printed circuit boards.

- Conducted thorough PCBA inspections to ensure all components were correctly mounted and soldered.

- Utilized precision tools and equipment to handle delicate components and achieve high levels of accuracy.

- Maintained a clean and organized work environment to prevent contamination and defects.

- Collaborated with engineers and technicians to troubleshoot and resolve technical issues.

- Adhered to strict quality control standards and industry best practices.

Frequently Asked Questions (FAQ’s) For Die Mounter

What is a Die Mounter?

A Die Mounter is a skilled professional responsible for mounting semiconductor dies onto substrates and printed circuit boards. They use precision tools and equipment to place and bond dies with extreme accuracy, ensuring the proper electrical connections and overall functionality of electronic devices.

What are the key skills required for a Die Mounter?

Die Mounters require a combination of technical skills and attention to detail. They should be proficient in Die Bonding, Wire Bonding, Flip Chip Bonding, BGA/CSP Mounting, SMT Assembly, and PCBA Inspection. They must also have a strong understanding of semiconductor packaging and assembly processes.

What is the work environment of a Die Mounter like?

Die Mounters typically work in clean and controlled environments, such as semiconductor fabrication facilities or electronics manufacturing plants. They may work in teams or independently, depending on the size and structure of the organization.

What are the career prospects for a Die Mounter?

Die Mounters with strong skills and experience can advance to supervisory or management roles within the semiconductor industry. They may also specialize in specific areas, such as advanced packaging or failure analysis.

How can I become a Die Mounter?

To become a Die Mounter, you typically need a Bachelor’s Degree in Electrical Engineering or a related field. Relevant work experience in semiconductor manufacturing or assembly is also highly valued. Additionally, certification programs or training courses can enhance your skills and knowledge.

What is the average salary for a Die Mounter?

The average salary for a Die Mounter can vary depending on factors such as experience, location, and industry. According to Salary.com, the average salary for a Die Mounter in the United States is around $75,000 per year.