Are you a seasoned Direct Chill Casting Operator (DC Casting Operator) seeking a new career path? Discover our professionally built Direct Chill Casting Operator (DC Casting Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

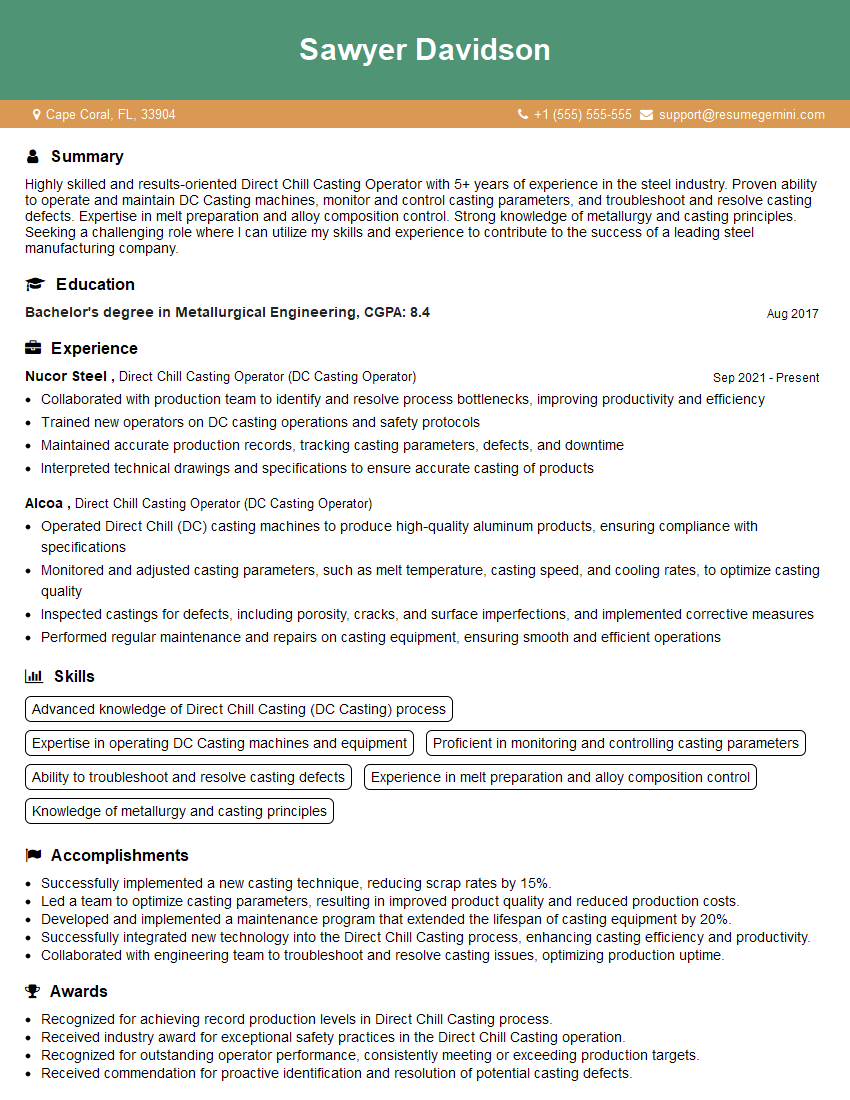

Sawyer Davidson

Direct Chill Casting Operator (DC Casting Operator)

Summary

Highly skilled and results-oriented Direct Chill Casting Operator with 5+ years of experience in the steel industry. Proven ability to operate and maintain DC Casting machines, monitor and control casting parameters, and troubleshoot and resolve casting defects. Expertise in melt preparation and alloy composition control. Strong knowledge of metallurgy and casting principles.

Seeking a challenging role where I can utilize my skills and experience to contribute to the success of a leading steel manufacturing company.

Education

Bachelor’s degree in Metallurgical Engineering

August 2017

Skills

- Advanced knowledge of Direct Chill Casting (DC Casting) process

- Expertise in operating DC Casting machines and equipment

- Proficient in monitoring and controlling casting parameters

- Ability to troubleshoot and resolve casting defects

- Experience in melt preparation and alloy composition control

- Knowledge of metallurgy and casting principles

Work Experience

Direct Chill Casting Operator (DC Casting Operator)

- Collaborated with production team to identify and resolve process bottlenecks, improving productivity and efficiency

- Trained new operators on DC casting operations and safety protocols

- Maintained accurate production records, tracking casting parameters, defects, and downtime

- Interpreted technical drawings and specifications to ensure accurate casting of products

Direct Chill Casting Operator (DC Casting Operator)

- Operated Direct Chill (DC) casting machines to produce high-quality aluminum products, ensuring compliance with specifications

- Monitored and adjusted casting parameters, such as melt temperature, casting speed, and cooling rates, to optimize casting quality

- Inspected castings for defects, including porosity, cracks, and surface imperfections, and implemented corrective measures

- Performed regular maintenance and repairs on casting equipment, ensuring smooth and efficient operations

Accomplishments

- Successfully implemented a new casting technique, reducing scrap rates by 15%.

- Led a team to optimize casting parameters, resulting in improved product quality and reduced production costs.

- Developed and implemented a maintenance program that extended the lifespan of casting equipment by 20%.

- Successfully integrated new technology into the Direct Chill Casting process, enhancing casting efficiency and productivity.

- Collaborated with engineering team to troubleshoot and resolve casting issues, optimizing production uptime.

Awards

- Recognized for achieving record production levels in Direct Chill Casting process.

- Received industry award for exceptional safety practices in the Direct Chill Casting operation.

- Recognized for outstanding operator performance, consistently meeting or exceeding production targets.

- Received commendation for proactive identification and resolution of potential casting defects.

Certificates

- Certified Direct Chill Casting Operator (CDCCO)

- Metallurgy Technician Certification

- ISO 9001:2015 Quality Management System Auditor

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Direct Chill Casting Operator (DC Casting Operator)

- Highlight your experience and skills in Direct Chill Casting.

- Quantify your accomplishments and results whenever possible.

- Use keywords that are relevant to the job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Direct Chill Casting Operator (DC Casting Operator) Resume

- Operate and maintain Direct Chill Casting machines and equipment

- Monitor and control casting parameters to ensure product quality

- Troubleshoot and resolve casting defects

- Prepare melt and control alloy composition

- Maintain a clean and safe work area

- Follow all safety procedures

- Work with other team members to achieve production goals

Frequently Asked Questions (FAQ’s) For Direct Chill Casting Operator (DC Casting Operator)

What is the role of a Direct Chill Casting Operator?

A Direct Chill Casting Operator is responsible for operating and maintaining Direct Chill Casting machines, monitoring and controlling casting parameters, and troubleshooting and resolving casting defects.

What are the qualifications for becoming a Direct Chill Casting Operator?

Most Direct Chill Casting Operators have a bachelor’s degree in Metallurgical Engineering or a related field.

What is the work environment of a Direct Chill Casting Operator?

Direct Chill Casting Operators typically work in a hot and noisy environment.

What are the career prospects for a Direct Chill Casting Operator?

Direct Chill Casting Operators can advance to positions such as Casting Supervisor, Production Manager, or Quality Control Manager.

What are the challenges of being a Direct Chill Casting Operator?

The challenges of being a Direct Chill Casting Operator include working in a hot and noisy environment, and dealing with the potential hazards of molten metal.

What are the rewards of being a Direct Chill Casting Operator?

The rewards of being a Direct Chill Casting Operator include a good salary, benefits, and the opportunity to work with a team of professionals.

What is the future of the Direct Chill Casting industry?

The future of the Direct Chill Casting industry is bright, as the demand for steel continues to grow.