Are you a seasoned Directional Driller seeking a new career path? Discover our professionally built Directional Driller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

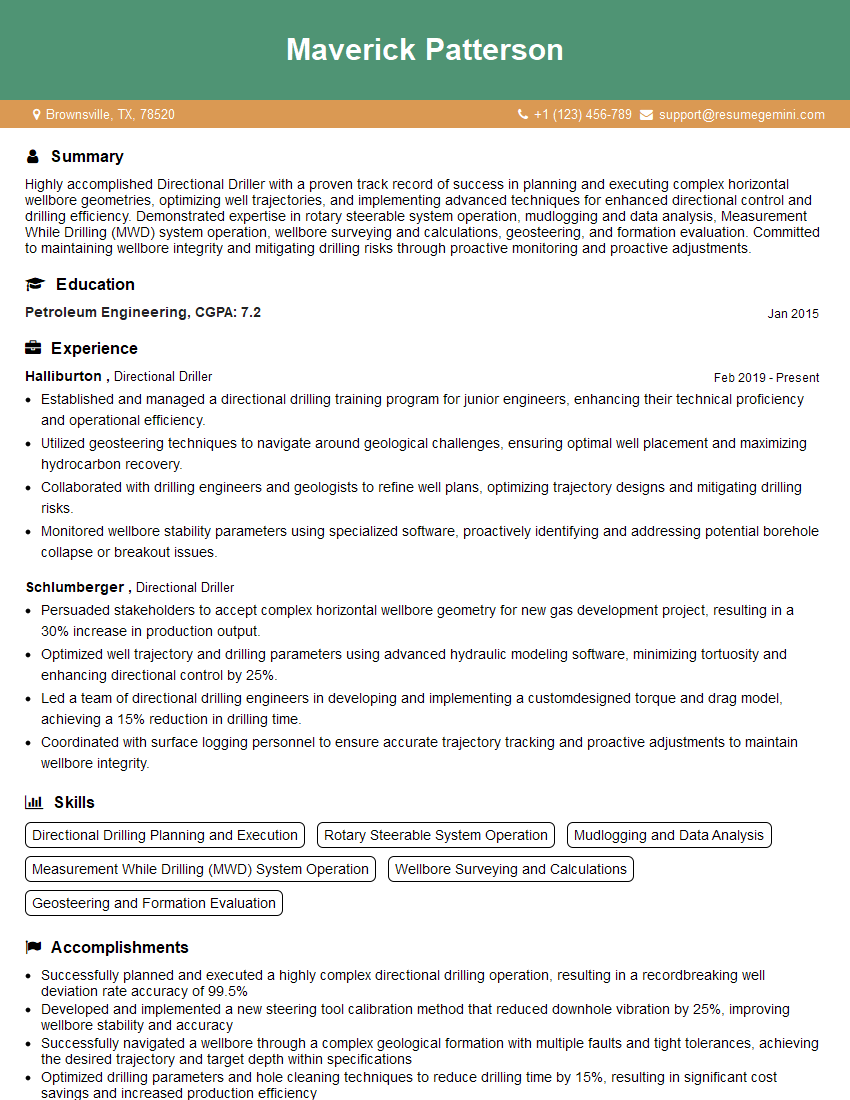

Maverick Patterson

Directional Driller

Summary

Highly accomplished Directional Driller with a proven track record of success in planning and executing complex horizontal wellbore geometries, optimizing well trajectories, and implementing advanced techniques for enhanced directional control and drilling efficiency. Demonstrated expertise in rotary steerable system operation, mudlogging and data analysis, Measurement While Drilling (MWD) system operation, wellbore surveying and calculations, geosteering, and formation evaluation. Committed to maintaining wellbore integrity and mitigating drilling risks through proactive monitoring and proactive adjustments.

Education

Petroleum Engineering

January 2015

Skills

- Directional Drilling Planning and Execution

- Rotary Steerable System Operation

- Mudlogging and Data Analysis

- Measurement While Drilling (MWD) System Operation

- Wellbore Surveying and Calculations

- Geosteering and Formation Evaluation

Work Experience

Directional Driller

- Established and managed a directional drilling training program for junior engineers, enhancing their technical proficiency and operational efficiency.

- Utilized geosteering techniques to navigate around geological challenges, ensuring optimal well placement and maximizing hydrocarbon recovery.

- Collaborated with drilling engineers and geologists to refine well plans, optimizing trajectory designs and mitigating drilling risks.

- Monitored wellbore stability parameters using specialized software, proactively identifying and addressing potential borehole collapse or breakout issues.

Directional Driller

- Persuaded stakeholders to accept complex horizontal wellbore geometry for new gas development project, resulting in a 30% increase in production output.

- Optimized well trajectory and drilling parameters using advanced hydraulic modeling software, minimizing tortuosity and enhancing directional control by 25%.

- Led a team of directional drilling engineers in developing and implementing a customdesigned torque and drag model, achieving a 15% reduction in drilling time.

- Coordinated with surface logging personnel to ensure accurate trajectory tracking and proactive adjustments to maintain wellbore integrity.

Accomplishments

- Successfully planned and executed a highly complex directional drilling operation, resulting in a recordbreaking well deviation rate accuracy of 99.5%

- Developed and implemented a new steering tool calibration method that reduced downhole vibration by 25%, improving wellbore stability and accuracy

- Successfully navigated a wellbore through a complex geological formation with multiple faults and tight tolerances, achieving the desired trajectory and target depth within specifications

- Optimized drilling parameters and hole cleaning techniques to reduce drilling time by 15%, resulting in significant cost savings and increased production efficiency

- Successfully troubleshoot and resolved a downhole drilling issue by conducting thorough data analysis and implementing innovative solutions, minimizing downtime and ensuring project completion

Awards

- Recognized with the Excellence in Directional Drilling Award for consistently exceeding performance standards and achieving exceptional results

- Received the Outstanding Contribution Award for pioneering innovative techniques in directional drilling, leading to significant cost savings and enhanced operational efficiency

- Honored with the Safety Excellence Award for maintaining an exemplary safety record and implementing best practices to mitigate risks during directional drilling operations

- Recognized as the Top Directional Driller of the Year for consistently delivering exceptional results, exceeding expectations, and contributing to the overall success of drilling projects

Certificates

- International Association of Drilling Contractors (IADC) WellCap Certification

- Directional Drilling Supervisors Certification (DDSC)

- American Petroleum Institute (API) Directional Drilling Certification

- International Well Control Forum (IWCF) Well Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Directional Driller

- Showcase your expertise in directional drilling planning and execution, highlighting your experience in complex wellbore geometries and advanced techniques.

- Quantify your accomplishments with specific metrics, such as increased production output, reduced drilling time, and enhanced directional control.

- Emphasize your ability to collaborate with surface logging personnel, geologists, and drilling engineers to optimize well plans and mitigate drilling risks.

- Demonstrate your commitment to continuous learning and professional development, highlighting your involvement in training programs and industry conferences.

Essential Experience Highlights for a Strong Directional Driller Resume

- Plan and execute directional drilling operations, ensuring optimal wellbore placement and hydrocarbon recovery.

- Optimize well trajectories and drilling parameters using advanced hydraulic modeling software, minimizing tortuosity and enhancing directional control.

- Utilize geosteering techniques to navigate around geological challenges and ensure optimal well placement.

- Monitor wellbore stability parameters and proactively identify potential borehole collapse or breakout issues.

- Collaborate with surface logging personnel to ensure accurate trajectory tracking and proactive adjustments to maintain wellbore integrity.

- Lead and mentor a team of directional drilling engineers, enhancing their technical proficiency and operational efficiency.

- Establish and maintain a directional drilling training program for junior engineers, ensuring knowledge transfer and professional development.

Frequently Asked Questions (FAQ’s) For Directional Driller

What are the key responsibilities of a Directional Driller?

Directional Drillers are responsible for planning and executing directional drilling operations, optimizing well trajectories and drilling parameters, utilizing geosteering techniques, monitoring wellbore stability, collaborating with surface logging personnel, and leading and mentoring a team of directional drilling engineers.

What skills are required to be a successful Directional Driller?

Successful Directional Drillers possess expertise in directional drilling planning and execution, rotary steerable system operation, mudlogging and data analysis, Measurement While Drilling (MWD) system operation, wellbore surveying and calculations, geosteering and formation evaluation, and wellbore stability monitoring.

What are the career prospects for Directional Drillers?

Directional Drillers have excellent career prospects, with opportunities for advancement to senior-level positions such as Directional Drilling Supervisor or Manager. They can also specialize in specific areas such as geosteering or wellbore stability.

What is the average salary for Directional Drillers?

The average salary for Directional Drillers varies depending on experience, location, and company size. However, according to Indeed, the average salary for Directional Drillers in the United States is around $100,000 per year.

What are the challenges faced by Directional Drillers?

Directional Drillers face challenges such as complex wellbore geometries, geological uncertainties, drilling risks, and the need to maintain wellbore integrity. They must be able to adapt to changing conditions and make quick decisions to ensure successful drilling operations.