Are you a seasoned Director of Manufacturing seeking a new career path? Discover our professionally built Director of Manufacturing Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

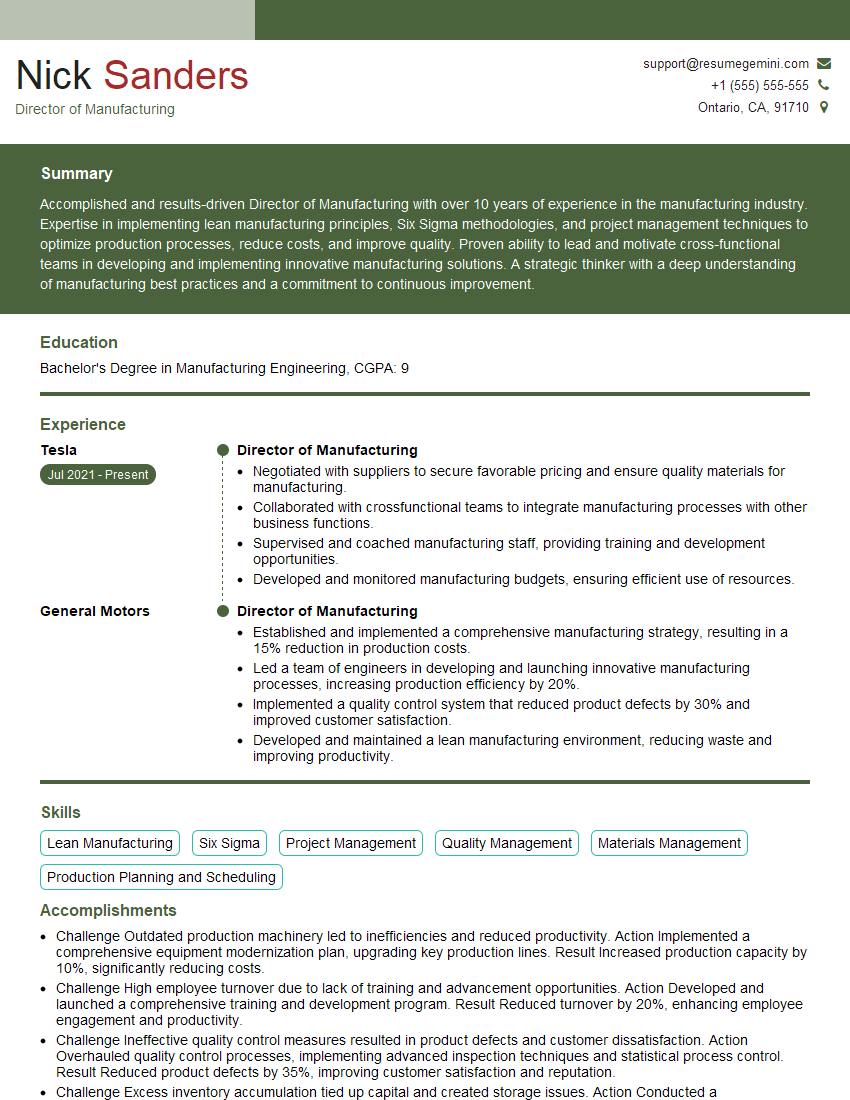

Nick Sanders

Director of Manufacturing

Summary

Accomplished and results-driven Director of Manufacturing with over 10 years of experience in the manufacturing industry. Expertise in implementing lean manufacturing principles, Six Sigma methodologies, and project management techniques to optimize production processes, reduce costs, and improve quality. Proven ability to lead and motivate cross-functional teams in developing and implementing innovative manufacturing solutions. A strategic thinker with a deep understanding of manufacturing best practices and a commitment to continuous improvement.

Education

Bachelor’s Degree in Manufacturing Engineering

June 2017

Skills

- Lean Manufacturing

- Six Sigma

- Project Management

- Quality Management

- Materials Management

- Production Planning and Scheduling

Work Experience

Director of Manufacturing

- Negotiated with suppliers to secure favorable pricing and ensure quality materials for manufacturing.

- Collaborated with crossfunctional teams to integrate manufacturing processes with other business functions.

- Supervised and coached manufacturing staff, providing training and development opportunities.

- Developed and monitored manufacturing budgets, ensuring efficient use of resources.

Director of Manufacturing

- Established and implemented a comprehensive manufacturing strategy, resulting in a 15% reduction in production costs.

- Led a team of engineers in developing and launching innovative manufacturing processes, increasing production efficiency by 20%.

- Implemented a quality control system that reduced product defects by 30% and improved customer satisfaction.

- Developed and maintained a lean manufacturing environment, reducing waste and improving productivity.

Accomplishments

- Challenge Outdated production machinery led to inefficiencies and reduced productivity. Action Implemented a comprehensive equipment modernization plan, upgrading key production lines. Result Increased production capacity by 10%, significantly reducing costs.

- Challenge High employee turnover due to lack of training and advancement opportunities. Action Developed and launched a comprehensive training and development program. Result Reduced turnover by 20%, enhancing employee engagement and productivity.

- Challenge Ineffective quality control measures resulted in product defects and customer dissatisfaction. Action Overhauled quality control processes, implementing advanced inspection techniques and statistical process control. Result Reduced product defects by 35%, improving customer satisfaction and reputation.

- Challenge Excess inventory accumulation tied up capital and created storage issues. Action Conducted a comprehensive inventory analysis and implemented a justintime ordering system. Result Reduced inventory levels by 25%, freeing up capital and optimizing storage space.

- Challenge Safety incidents due to inadequate safety protocols. Action Developed and implemented a comprehensive safety program, including training, inspections, and hazard assessments. Result Reduced safety incidents by 40%, creating a safer work environment for employees.

Awards

- Manufacturing Excellence Award for implementing innovative production techniques, leading to a 15% increase in efficiency.

- Lean Six Sigma Black Belt certification for expertise in process improvement and waste reduction.

- Industry Recognition for exceptional leadership in manufacturing operations, fostering a culture of continuous improvement.

- Distinguished Manufacturer Award for outstanding contributions to the manufacturing industry.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production and Inventory Manager (CPIM)

- Certified Six Sigma Black Belt

- Certified Quality Manager (CQM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Director of Manufacturing

- Quantify your accomplishments with specific metrics and data to demonstrate the impact of your contributions.

- Highlight your experience in implementing lean manufacturing principles and Six Sigma methodologies, as these are highly sought-after skills in the manufacturing industry.

- Showcase your leadership abilities and experience in motivating and managing cross-functional teams.

- Emphasize your understanding of industry best practices, such as ISO 9001 and TS 16949, and how you have applied them in your previous roles.

- Tailor your resume to the specific requirements of each job you apply for, highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Director of Manufacturing Resume

- Develop and implement comprehensive manufacturing strategies to drive operational excellence.

- Lead engineering teams in the design and implementation of innovative manufacturing processes to enhance production efficiency.

- Establish and maintain quality control systems to ensure product quality and customer satisfaction.

- Implement lean manufacturing principles to reduce waste, improve productivity, and optimize resource utilization.

- Negotiate with suppliers to secure favorable pricing and ensure the supply of high-quality materials.

- Collaborate with cross-functional teams to integrate manufacturing processes with other business functions to achieve overall organizational goals.

- Provide strategic guidance and direction to manufacturing staff, fostering a culture of continuous improvement and innovation.

Frequently Asked Questions (FAQ’s) For Director of Manufacturing

What are the key responsibilities of a Director of Manufacturing?

The key responsibilities of a Director of Manufacturing include developing and implementing manufacturing strategies, leading engineering teams in process innovation, establishing quality control systems, implementing lean manufacturing principles, negotiating with suppliers, collaborating with cross-functional teams, and providing strategic guidance to manufacturing staff.

What qualifications are required to become a Director of Manufacturing?

To become a Director of Manufacturing, you typically need a bachelor’s degree in manufacturing engineering or a related field, along with several years of experience in manufacturing management. Strong leadership skills, a deep understanding of manufacturing best practices, and experience in implementing lean manufacturing principles and Six Sigma methodologies are also essential.

What are the career prospects for a Director of Manufacturing?

The career prospects for a Director of Manufacturing are excellent, as the demand for skilled manufacturing professionals continues to grow. With experience and proven success, Directors of Manufacturing can advance to senior leadership roles within their organizations or pursue consulting opportunities.

What are the challenges faced by Directors of Manufacturing?

Directors of Manufacturing face several challenges, including the need to continuously improve efficiency and productivity, manage supply chain disruptions, and adapt to changing industry trends. They must also ensure that their manufacturing operations are compliant with industry regulations and environmental standards.

What are the key skills required for a Director of Manufacturing?

Key skills required for a Director of Manufacturing include strategic planning, operational management, process innovation, quality control, lean manufacturing principles, Six Sigma methodologies, project management, negotiation, and communication.

What is the average salary for a Director of Manufacturing?

The average salary for a Director of Manufacturing in the United States is around $120,000 per year, according to Salary.com. However, salaries can vary depending on experience, industry, and location.