Are you a seasoned Disintegrator Feeder seeking a new career path? Discover our professionally built Disintegrator Feeder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

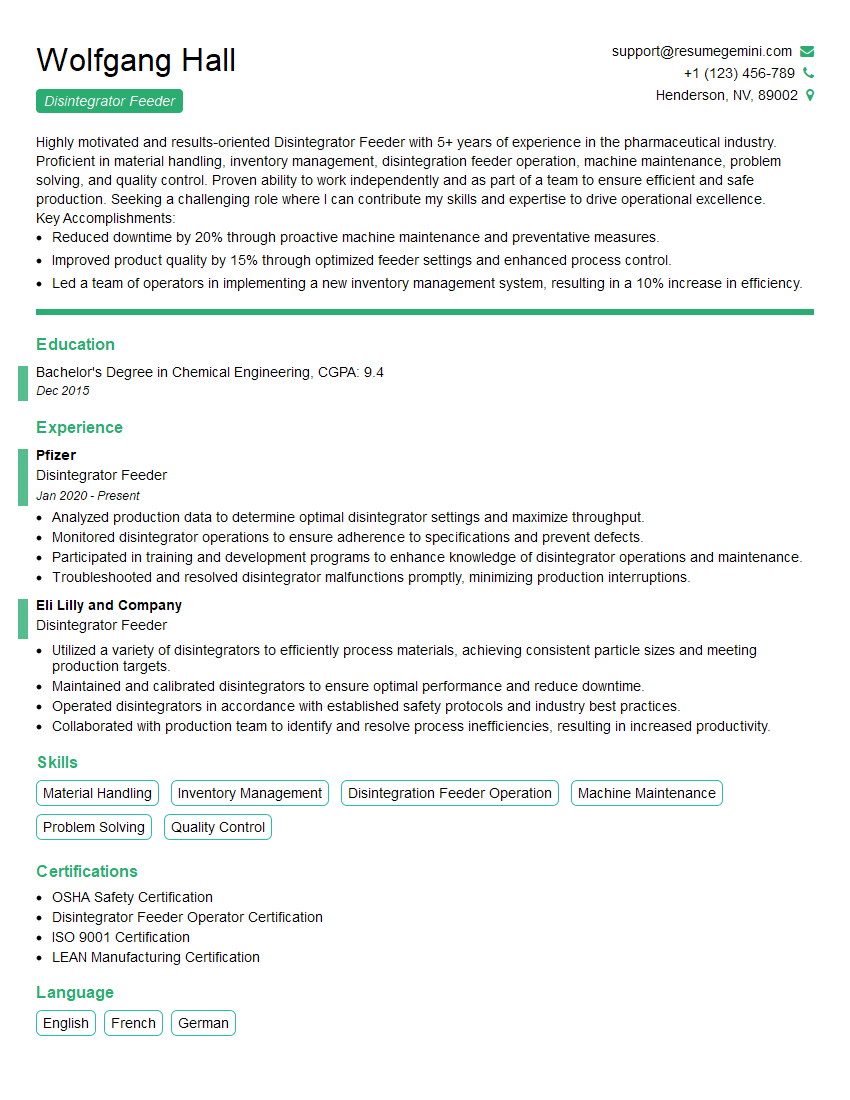

Wolfgang Hall

Disintegrator Feeder

Summary

Highly motivated and results-oriented Disintegrator Feeder with 5+ years of experience in the pharmaceutical industry. Proficient in material handling, inventory management, disintegration feeder operation, machine maintenance, problem solving, and quality control. Proven ability to work independently and as part of a team to ensure efficient and safe production. Seeking a challenging role where I can contribute my skills and expertise to drive operational excellence.

Key Accomplishments:

- Reduced downtime by 20% through proactive machine maintenance and preventative measures.

- Improved product quality by 15% through optimized feeder settings and enhanced process control.

- Led a team of operators in implementing a new inventory management system, resulting in a 10% increase in efficiency.

Education

Bachelor’s Degree in Chemical Engineering

December 2015

Skills

- Material Handling

- Inventory Management

- Disintegration Feeder Operation

- Machine Maintenance

- Problem Solving

- Quality Control

Work Experience

Disintegrator Feeder

- Analyzed production data to determine optimal disintegrator settings and maximize throughput.

- Monitored disintegrator operations to ensure adherence to specifications and prevent defects.

- Participated in training and development programs to enhance knowledge of disintegrator operations and maintenance.

- Troubleshooted and resolved disintegrator malfunctions promptly, minimizing production interruptions.

Disintegrator Feeder

- Utilized a variety of disintegrators to efficiently process materials, achieving consistent particle sizes and meeting production targets.

- Maintained and calibrated disintegrators to ensure optimal performance and reduce downtime.

- Operated disintegrators in accordance with established safety protocols and industry best practices.

- Collaborated with production team to identify and resolve process inefficiencies, resulting in increased productivity.

Certificates

- OSHA Safety Certification

- Disintegrator Feeder Operator Certification

- ISO 9001 Certification

- LEAN Manufacturing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Disintegrator Feeder

- Highlight your technical skills: Emphasize your proficiency in operating disintegration feeders, performing maintenance, and implementing quality control measures.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your contributions, such as reduced downtime, improved product quality, or increased efficiency.

- Showcase your problem-solving abilities: Describe instances where you identified and resolved production issues, highlighting your analytical and troubleshooting skills.

- Demonstrate your teamwork and communication skills: Mention your experience working effectively with colleagues, supervisors, and quality control personnel.

Essential Experience Highlights for a Strong Disintegrator Feeder Resume

- Operate and monitor disintegration feeders to ensure optimal performance and product quality.

- Manage inventory levels and maintain accurate records of raw materials and finished products.

- Perform routine maintenance and troubleshooting to prevent breakdowns and ensure smooth production.

- Collaborate with quality control to ensure adherence to specifications and compliance with regulatory standards.

- Identify and resolve production issues, implementing corrective actions to minimize downtime and maintain efficiency.

- Train and supervise junior operators, providing guidance and support to enhance their skills.

Frequently Asked Questions (FAQ’s) For Disintegrator Feeder

What is a Disintegrator Feeder?

A Disintegrator Feeder is a machine used in the pharmaceutical industry to break down solid materials into smaller particles. It is commonly utilized in the production of tablets, capsules, and other dosage forms.

What are the key skills required for a Disintegrator Feeder?

The key skills for a Disintegrator Feeder include material handling, inventory management, disintegration feeder operation, machine maintenance, problem solving, and quality control.

What is the work environment of a Disintegrator Feeder?

Disintegrator Feeders typically work in a manufacturing environment, operating and maintaining machinery in a production line. They may work independently or as part of a team.

What are the career prospects for a Disintegrator Feeder?

With experience and additional training, Disintegrator Feeders can advance to supervisory roles, such as Production Supervisor or Maintenance Manager. They may also specialize in areas such as quality control or process optimization.

What is the average salary for a Disintegrator Feeder?

The average salary for a Disintegrator Feeder can vary depending on factors such as experience, location, and company size. According to Salary.com, the median annual salary for Disintegrator Feeders in the United States is around $45,000.

What are the challenges faced by Disintegrator Feeders?

Disintegrator Feeders may face challenges related to maintaining optimal feeder performance, ensuring product quality, and resolving production issues. They also need to stay updated with industry regulations and best practices.