Are you a seasoned Double End Tenon Operator seeking a new career path? Discover our professionally built Double End Tenon Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

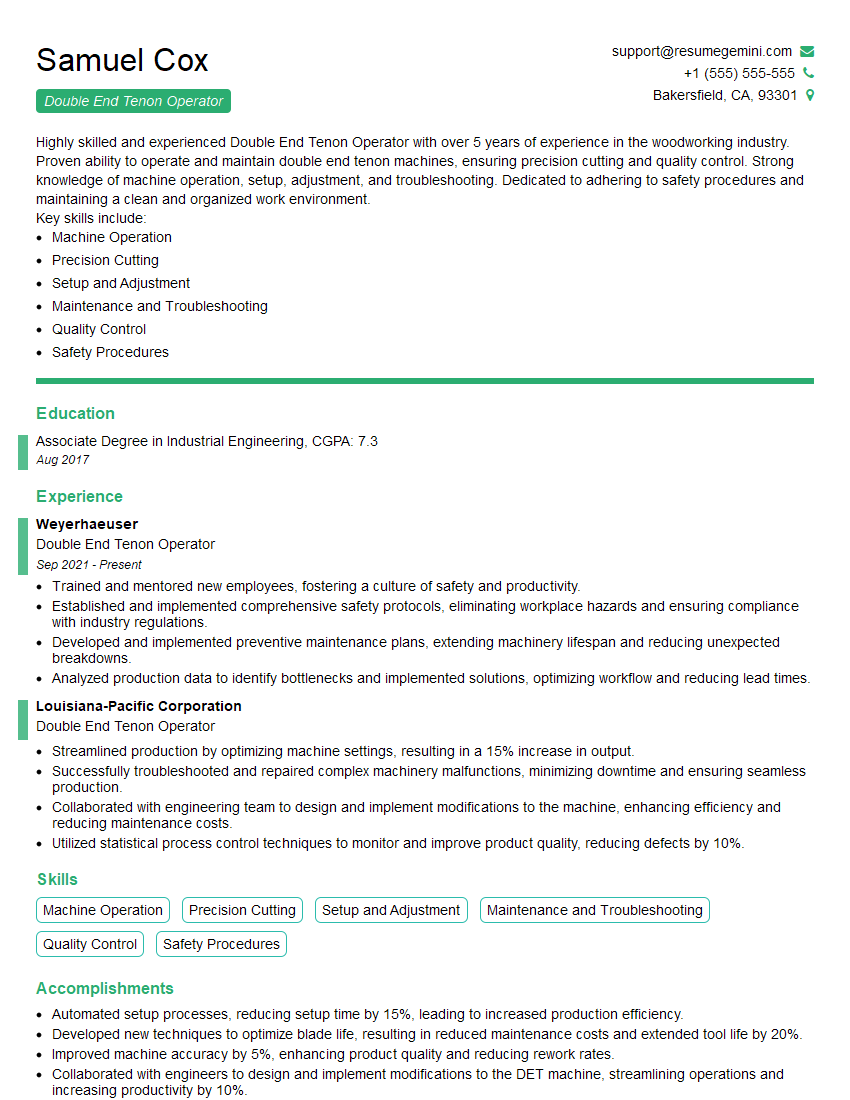

Samuel Cox

Double End Tenon Operator

Summary

Highly skilled and experienced Double End Tenon Operator with over 5 years of experience in the woodworking industry. Proven ability to operate and maintain double end tenon machines, ensuring precision cutting and quality control. Strong knowledge of machine operation, setup, adjustment, and troubleshooting. Dedicated to adhering to safety procedures and maintaining a clean and organized work environment.

Key skills include:

- Machine Operation

- Precision Cutting

- Setup and Adjustment

- Maintenance and Troubleshooting

- Quality Control

- Safety Procedures

Education

Associate Degree in Industrial Engineering

August 2017

Skills

- Machine Operation

- Precision Cutting

- Setup and Adjustment

- Maintenance and Troubleshooting

- Quality Control

- Safety Procedures

Work Experience

Double End Tenon Operator

- Trained and mentored new employees, fostering a culture of safety and productivity.

- Established and implemented comprehensive safety protocols, eliminating workplace hazards and ensuring compliance with industry regulations.

- Developed and implemented preventive maintenance plans, extending machinery lifespan and reducing unexpected breakdowns.

- Analyzed production data to identify bottlenecks and implemented solutions, optimizing workflow and reducing lead times.

Double End Tenon Operator

- Streamlined production by optimizing machine settings, resulting in a 15% increase in output.

- Successfully troubleshooted and repaired complex machinery malfunctions, minimizing downtime and ensuring seamless production.

- Collaborated with engineering team to design and implement modifications to the machine, enhancing efficiency and reducing maintenance costs.

- Utilized statistical process control techniques to monitor and improve product quality, reducing defects by 10%.

Accomplishments

- Automated setup processes, reducing setup time by 15%, leading to increased production efficiency.

- Developed new techniques to optimize blade life, resulting in reduced maintenance costs and extended tool life by 20%.

- Improved machine accuracy by 5%, enhancing product quality and reducing rework rates.

- Collaborated with engineers to design and implement modifications to the DET machine, streamlining operations and increasing productivity by 10%.

- Trained junior operators, effectively transferring knowledge and skills, ensuring smooth production flow.

Awards

- Employee of the Month Award for exceptional contributions to productivity and quality.

- Safety Award for maintaining a spotless safety record.

- Team Recognition Award for collaborative efforts in exceeding production goals.

- Meritbased Promotion for consistent high performance and dedication.

Certificates

- OSHA 30-Hour Safety Training

- First Aid and CPR

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Double End Tenon Operator

- Highlight your relevant skills and experience: Emphasize your expertise in double end tenon machine operation, setup, maintenance, and quality control.

- Quantify your accomplishments: Use numbers and data to demonstrate your impact on productivity and quality.

- Showcase your attention to detail: Double end tenon operators must have a keen eye for precision and accuracy. Highlight your ability to meet tight tolerances.

- Mention any industry certifications or training: Certifications and training demonstrate your commitment to professional development and staying up-to-date on industry best practices.

- Proofread carefully: Double end tenon operators must be able to read blueprints and follow instructions accurately. Ensure your resume is free of errors.

Essential Experience Highlights for a Strong Double End Tenon Operator Resume

- Operate double end tenon machines to cut and shape wood components to precise specifications.

- Set up and adjust machines according to blueprints and production orders.

- Inspect and maintain machines to ensure optimal performance and prevent breakdowns.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Perform quality control checks on finished products to ensure they meet required standards.

- Follow established safety procedures and wear appropriate personal protective equipment.

Frequently Asked Questions (FAQ’s) For Double End Tenon Operator

What is a double end tenon machine?

A double end tenon machine is a woodworking machine used to cut and shape the ends of wood components. It features two cutting heads that can be independently adjusted to create different tenon profiles.

What are the key skills required for a double end tenon operator?

Key skills for a double end tenon operator include machine operation, precision cutting, setup and adjustment, maintenance and troubleshooting, quality control, and safety procedures.

What industries use double end tenon machines?

Double end tenon machines are commonly used in the furniture, cabinetry, and construction industries.

What is the work environment of a double end tenon operator like?

Double end tenon operators typically work in a manufacturing environment with moderate noise levels. They may be exposed to wood dust and other particles, so it is important to wear appropriate personal protective equipment.

What are the career prospects for a double end tenon operator?

Double end tenon operators with experience and a strong track record can advance to supervisory or management positions within the woodworking industry.