Are you a seasoned Drilling Machine Operator seeking a new career path? Discover our professionally built Drilling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

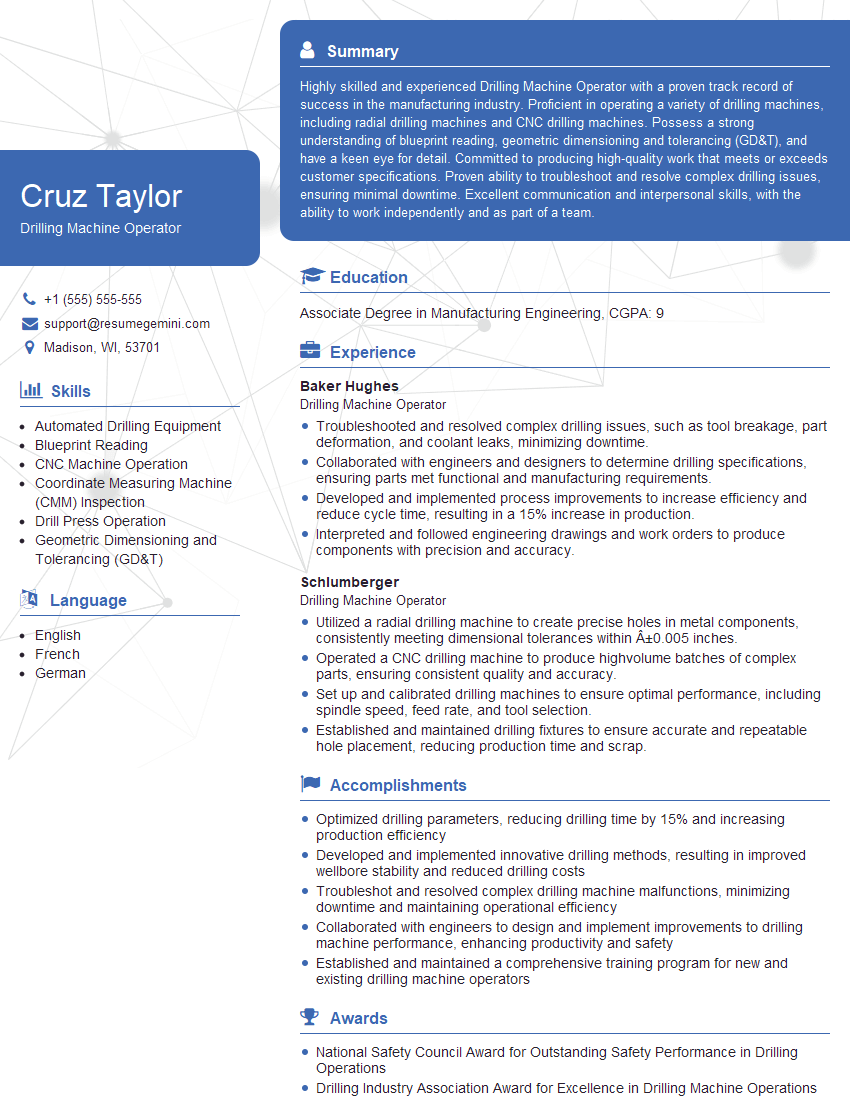

Cruz Taylor

Drilling Machine Operator

Summary

Highly skilled and experienced Drilling Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating a variety of drilling machines, including radial drilling machines and CNC drilling machines. Possess a strong understanding of blueprint reading, geometric dimensioning and tolerancing (GD&T), and have a keen eye for detail. Committed to producing high-quality work that meets or exceeds customer specifications. Proven ability to troubleshoot and resolve complex drilling issues, ensuring minimal downtime. Excellent communication and interpersonal skills, with the ability to work independently and as part of a team.

Education

Associate Degree in Manufacturing Engineering

May 2018

Skills

- Automated Drilling Equipment

- Blueprint Reading

- CNC Machine Operation

- Coordinate Measuring Machine (CMM) Inspection

- Drill Press Operation

- Geometric Dimensioning and Tolerancing (GD&T)

Work Experience

Drilling Machine Operator

- Troubleshooted and resolved complex drilling issues, such as tool breakage, part deformation, and coolant leaks, minimizing downtime.

- Collaborated with engineers and designers to determine drilling specifications, ensuring parts met functional and manufacturing requirements.

- Developed and implemented process improvements to increase efficiency and reduce cycle time, resulting in a 15% increase in production.

- Interpreted and followed engineering drawings and work orders to produce components with precision and accuracy.

Drilling Machine Operator

- Utilized a radial drilling machine to create precise holes in metal components, consistently meeting dimensional tolerances within ±0.005 inches.

- Operated a CNC drilling machine to produce highvolume batches of complex parts, ensuring consistent quality and accuracy.

- Set up and calibrated drilling machines to ensure optimal performance, including spindle speed, feed rate, and tool selection.

- Established and maintained drilling fixtures to ensure accurate and repeatable hole placement, reducing production time and scrap.

Accomplishments

- Optimized drilling parameters, reducing drilling time by 15% and increasing production efficiency

- Developed and implemented innovative drilling methods, resulting in improved wellbore stability and reduced drilling costs

- Troubleshot and resolved complex drilling machine malfunctions, minimizing downtime and maintaining operational efficiency

- Collaborated with engineers to design and implement improvements to drilling machine performance, enhancing productivity and safety

- Established and maintained a comprehensive training program for new and existing drilling machine operators

Awards

- National Safety Council Award for Outstanding Safety Performance in Drilling Operations

- Drilling Industry Association Award for Excellence in Drilling Machine Operations

- Company Recognition for Exceeding Production Goals in Drilling Machine Operations

- Drilling Machine Operator of the Year Award for Exceptional Performance and Contributions

Certificates

- CNC Certification

- CMM Operator Certification

- ISO 9001 Auditor Certification

- Lean Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drilling Machine Operator

- Highlight your experience and skills in operating different types of drilling machines, including radial drilling machines and CNC drilling machines.

- Showcase your knowledge of blueprint reading, geometric dimensioning and tolerancing (GD&T), and your ability to produce high-quality work that meets or exceeds customer specifications.

- Emphasize your problem-solving abilities and your experience in troubleshooting and resolving complex drilling issues, ensuring minimal downtime.

- Demonstrate your commitment to safety and your ability to work independently and as part of a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Drilling Machine Operator Resume

- Operate radial drilling machines to create precise holes in metal components, consistently meeting dimensional tolerances within ±0.005 inches.

- Operate CNC drilling machines to produce high-volume batches of complex parts, ensuring consistent quality and accuracy.

- Set up and calibrate drilling machines to ensure optimal performance, including spindle speed, feed rate, and tool selection.

- Establish and maintain drilling fixtures to ensure accurate and repeatable hole placement, reducing production time and scrap.

- Troubleshoot and resolve complex drilling issues, such as tool breakage, part deformation, and coolant leaks, minimizing downtime.

- Collaborate with engineers and designers to determine drilling specifications, ensuring parts met functional and manufacturing requirements.

- Develop and implement process improvements to increase efficiency and reduce cycle time, resulting in a 15% increase in production.

Frequently Asked Questions (FAQ’s) For Drilling Machine Operator

What is a Drilling Machine Operator?

A Drilling Machine Operator is a skilled professional who operates drilling machines to create holes in various materials, such as metal, wood, and plastic. They use different types of drilling machines, including radial drilling machines, CNC drilling machines, and drill presses, to produce precise and accurate holes according to specifications.

What are the key skills required for a Drilling Machine Operator?

Key skills required for a Drilling Machine Operator include the ability to operate different types of drilling machines, knowledge of blueprint reading and geometric dimensioning and tolerancing (GD&T), and a keen eye for detail. They must also have good problem-solving abilities and be able to troubleshoot and resolve complex drilling issues, ensuring minimal downtime.

What are the career prospects for a Drilling Machine Operator?

Drilling Machine Operators with the right skills and experience can advance their careers to become CNC programmers, manufacturing supervisors, or quality control inspectors. They can also specialize in a particular area of drilling, such as deep hole drilling or precision drilling.

What is the average salary for a Drilling Machine Operator?

The average salary for a Drilling Machine Operator in the United States is around $40,000 per year. However, salaries can vary depending on experience, skills, and location.

What are the working conditions for a Drilling Machine Operator?

Drilling Machine Operators typically work in manufacturing environments, often in factories or workshops. They may work with other machine operators, engineers, and quality control inspectors. Working conditions can be noisy and dusty, and operators may need to wear protective gear, such as safety glasses, earplugs, and gloves.

What are the educational requirements for a Drilling Machine Operator?

Most Drilling Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in manufacturing engineering or a related field.

What are the certification programs available for Drilling Machine Operators?

There are several certification programs available for Drilling Machine Operators, including the Certified Drilling Machine Operator (CDMO) certification from the National Institute for Metalworking Skills (NIMS) and the Certified Production Technician (CPT) certification from the Manufacturing Skill Standards Council (MSSC).