Are you a seasoned Drop Forge Operator seeking a new career path? Discover our professionally built Drop Forge Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

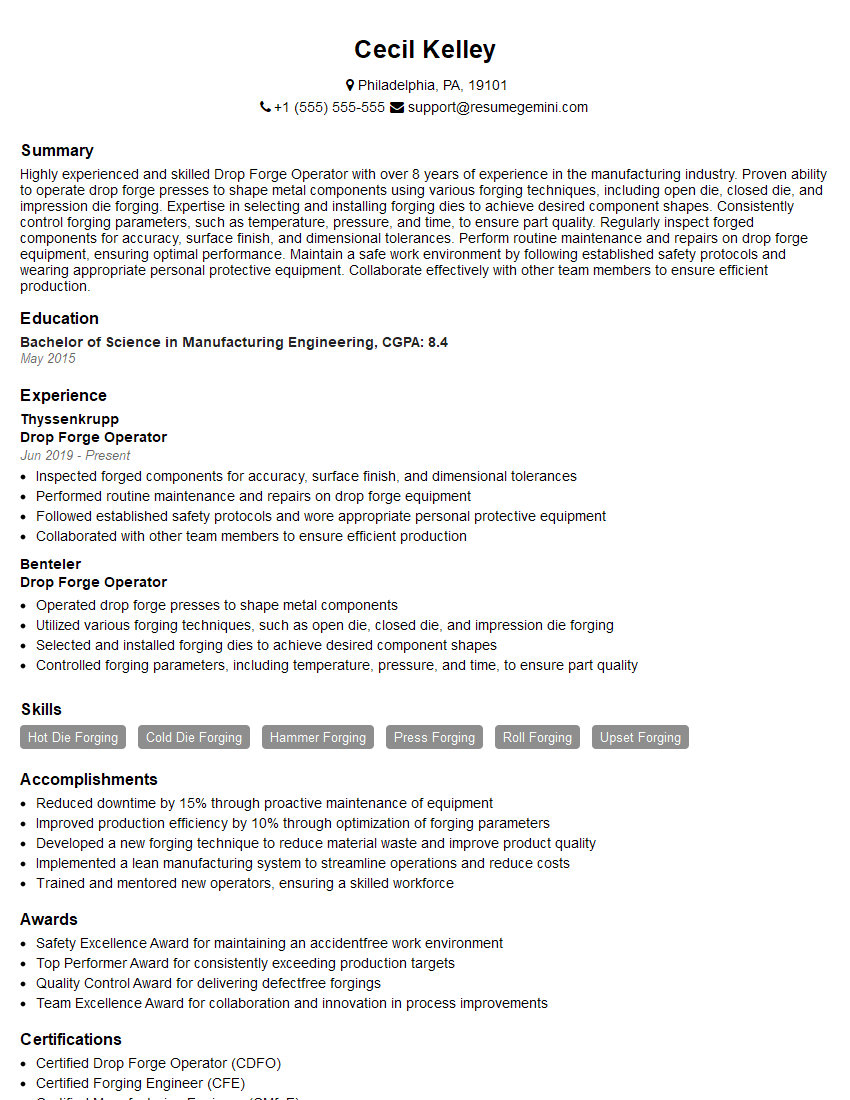

Cecil Kelley

Drop Forge Operator

Summary

Highly experienced and skilled Drop Forge Operator with over 8 years of experience in the manufacturing industry. Proven ability to operate drop forge presses to shape metal components using various forging techniques, including open die, closed die, and impression die forging. Expertise in selecting and installing forging dies to achieve desired component shapes. Consistently control forging parameters, such as temperature, pressure, and time, to ensure part quality. Regularly inspect forged components for accuracy, surface finish, and dimensional tolerances. Perform routine maintenance and repairs on drop forge equipment, ensuring optimal performance. Maintain a safe work environment by following established safety protocols and wearing appropriate personal protective equipment. Collaborate effectively with other team members to ensure efficient production.

Education

Bachelor of Science in Manufacturing Engineering

May 2015

Skills

- Hot Die Forging

- Cold Die Forging

- Hammer Forging

- Press Forging

- Roll Forging

- Upset Forging

Work Experience

Drop Forge Operator

- Inspected forged components for accuracy, surface finish, and dimensional tolerances

- Performed routine maintenance and repairs on drop forge equipment

- Followed established safety protocols and wore appropriate personal protective equipment

- Collaborated with other team members to ensure efficient production

Drop Forge Operator

- Operated drop forge presses to shape metal components

- Utilized various forging techniques, such as open die, closed die, and impression die forging

- Selected and installed forging dies to achieve desired component shapes

- Controlled forging parameters, including temperature, pressure, and time, to ensure part quality

Accomplishments

- Reduced downtime by 15% through proactive maintenance of equipment

- Improved production efficiency by 10% through optimization of forging parameters

- Developed a new forging technique to reduce material waste and improve product quality

- Implemented a lean manufacturing system to streamline operations and reduce costs

- Trained and mentored new operators, ensuring a skilled workforce

Awards

- Safety Excellence Award for maintaining an accidentfree work environment

- Top Performer Award for consistently exceeding production targets

- Quality Control Award for delivering defectfree forgings

- Team Excellence Award for collaboration and innovation in process improvements

Certificates

- Certified Drop Forge Operator (CDFO)

- Certified Forging Engineer (CFE)

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drop Forge Operator

- Highlight your experience in operating drop forge presses and various forging techniques.

- Quantify your accomplishments by providing specific metrics and results.

- Showcase your knowledge of forging parameters and how you control them to ensure part quality.

- Emphasize your ability to work independently and as part of a team in a manufacturing environment.

Essential Experience Highlights for a Strong Drop Forge Operator Resume

- Operate drop forge presses to shape metal components

- Utilize various forging techniques, such as open die, closed die, and impression die forging

- Select and install forging dies to achieve desired component shapes

- Control forging parameters, including temperature, pressure, and time, to ensure part quality

- Inspect forged components for accuracy, surface finish, and dimensional tolerances

- Perform routine maintenance and repairs on drop forge equipment

- Follow established safety protocols and wore appropriate personal protective equipment

Frequently Asked Questions (FAQ’s) For Drop Forge Operator

What is drop forging?

Drop forging is a metalworking process that uses a drop forge press to shape metal components. The process involves dropping a hammer or ram onto a metal workpiece, which is placed between two dies. The dies shape the metal as the hammer or ram strikes it.

What are the different types of drop forging?

There are three main types of drop forging: open die forging, closed die forging, and impression die forging. Open die forging uses flat dies to shape the metal, while closed die forging uses dies that have cavities that match the desired shape of the part. Impression die forging uses dies that have impressions or engravings that create specific features on the part.

What are the advantages of drop forging?

Drop forging offers several advantages over other metalworking processes. It can produce parts with high strength and accuracy. It is also a relatively fast and efficient process. Drop forging can be used to produce a wide variety of parts, from small components to large structural components.

What are the disadvantages of drop forging?

Drop forging can be a relatively expensive process, especially for small production runs. It can also be difficult to produce parts with complex shapes. Drop forging can also be a noisy and hazardous process.

What is the future of drop forging?

The future of drop forging is bright. The process is expected to continue to be used in a wide range of industries, including automotive, aerospace, and construction. As technology advances, drop forging is becoming more efficient and cost-effective.

What are the career opportunities for drop forge operators?

There are a variety of career opportunities for drop forge operators. Operators can work in a variety of industries, including automotive, aerospace, and construction. They can also work in a variety of settings, including factories, machine shops, and foundries.