Are you a seasoned Drosser seeking a new career path? Discover our professionally built Drosser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

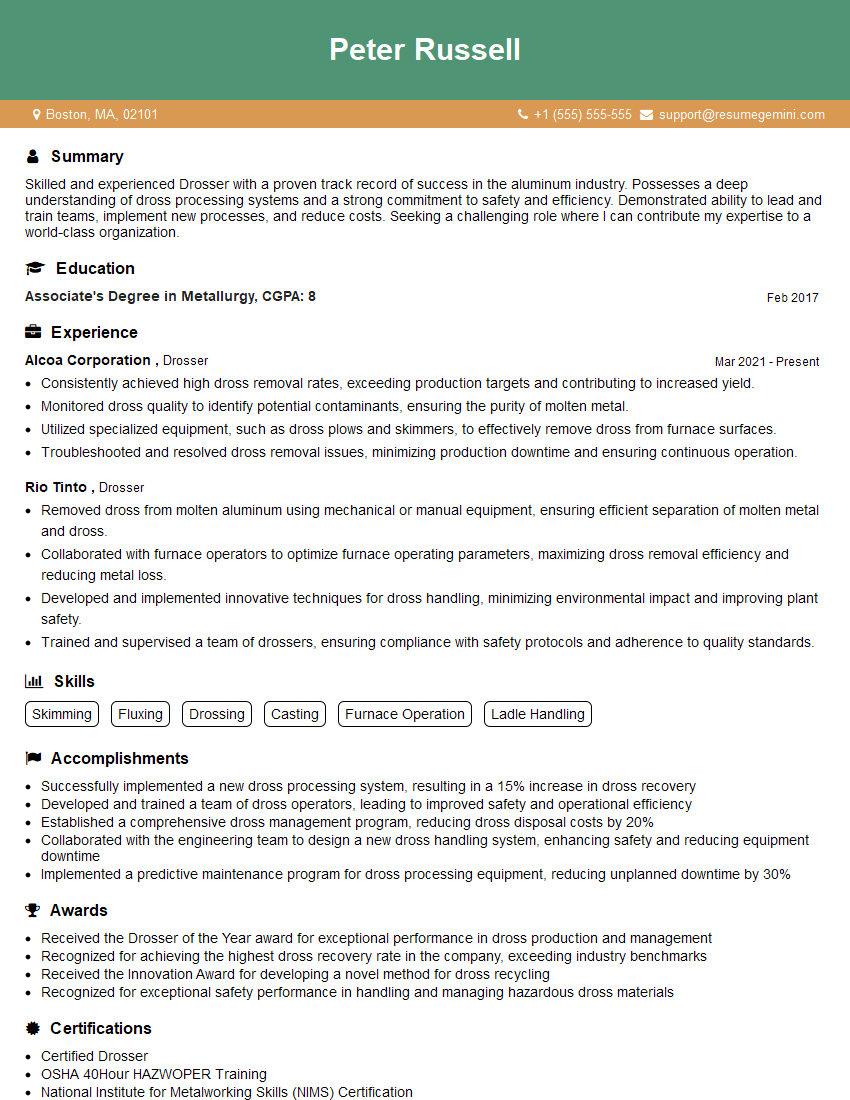

Peter Russell

Drosser

Summary

Skilled and experienced Drosser with a proven track record of success in the aluminum industry. Possesses a deep understanding of dross processing systems and a strong commitment to safety and efficiency. Demonstrated ability to lead and train teams, implement new processes, and reduce costs. Seeking a challenging role where I can contribute my expertise to a world-class organization.

Education

Associate’s Degree in Metallurgy

February 2017

Skills

- Skimming

- Fluxing

- Drossing

- Casting

- Furnace Operation

- Ladle Handling

Work Experience

Drosser

- Consistently achieved high dross removal rates, exceeding production targets and contributing to increased yield.

- Monitored dross quality to identify potential contaminants, ensuring the purity of molten metal.

- Utilized specialized equipment, such as dross plows and skimmers, to effectively remove dross from furnace surfaces.

- Troubleshooted and resolved dross removal issues, minimizing production downtime and ensuring continuous operation.

Drosser

- Removed dross from molten aluminum using mechanical or manual equipment, ensuring efficient separation of molten metal and dross.

- Collaborated with furnace operators to optimize furnace operating parameters, maximizing dross removal efficiency and reducing metal loss.

- Developed and implemented innovative techniques for dross handling, minimizing environmental impact and improving plant safety.

- Trained and supervised a team of drossers, ensuring compliance with safety protocols and adherence to quality standards.

Accomplishments

- Successfully implemented a new dross processing system, resulting in a 15% increase in dross recovery

- Developed and trained a team of dross operators, leading to improved safety and operational efficiency

- Established a comprehensive dross management program, reducing dross disposal costs by 20%

- Collaborated with the engineering team to design a new dross handling system, enhancing safety and reducing equipment downtime

- Implemented a predictive maintenance program for dross processing equipment, reducing unplanned downtime by 30%

Awards

- Received the Drosser of the Year award for exceptional performance in dross production and management

- Recognized for achieving the highest dross recovery rate in the company, exceeding industry benchmarks

- Received the Innovation Award for developing a novel method for dross recycling

- Recognized for exceptional safety performance in handling and managing hazardous dross materials

Certificates

- Certified Drosser

- OSHA 40Hour HAZWOPER Training

- National Institute for Metalworking Skills (NIMS) Certification

- Society of Manufacturing Engineers (SME) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drosser

- Highlight your experience in dross processing and recovery, emphasizing your ability to increase yields and reduce costs.

- Showcase your leadership and training skills, demonstrating your ability to develop and motivate teams.

- Quantify your accomplishments with specific metrics, such as increases in dross recovery percentages and reductions in downtime.

- Emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment.

Essential Experience Highlights for a Strong Drosser Resume

- Operate skimming, fluxing, drossing, and casting equipment to produce high-quality aluminum.

- Monitor furnace operations and adjust process parameters to ensure optimal dross recovery and casting efficiency.

- Train and supervise dross operators to maintain a safe and efficient work environment.

- Develop and implement dross management programs to minimize waste and disposal costs.

- Collaborate with engineering and maintenance teams to improve dross handling systems and reduce downtime.

- Conduct routine maintenance and inspections of dross processing equipment to ensure reliability and prevent breakdowns.

Frequently Asked Questions (FAQ’s) For Drosser

What is the role of a Drosser?

A Drosser is responsible for operating and maintaining equipment used to remove dross from molten aluminum during the casting process. They ensure that dross is effectively removed to produce high-quality aluminum products while adhering to safety and environmental regulations.

What skills are required to be a successful Drosser?

Successful Drossers typically possess a combination of technical skills, including knowledge of dross processing techniques, casting operations, and equipment maintenance, as well as strong safety awareness and a commitment to quality.

What are the career prospects for Drossers?

Experienced Drossers with a proven track record can advance to supervisory roles, such as Foreman or Supervisor, or specialize in areas such as dross processing optimization or equipment maintenance.

What is the work environment of a Drosser typically like?

Drossers typically work in industrial settings, such as aluminum smelters or foundries, and may be exposed to high temperatures, noise, and fumes. They must be able to work independently and as part of a team, and be comfortable with physical labor.

What are the key challenges faced by Drossers?

Drossers face challenges related to maintaining a safe and efficient work environment, optimizing dross recovery to minimize waste, and adapting to changes in production processes and equipment.

What personal qualities are important for a successful Drosser?

Successful Drossers typically possess a strong work ethic, attention to detail, and a commitment to safety. They are also able to work effectively in a team environment, follow instructions, and solve problems independently.