Are you a seasoned Dry Kiln Operator Helper seeking a new career path? Discover our professionally built Dry Kiln Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

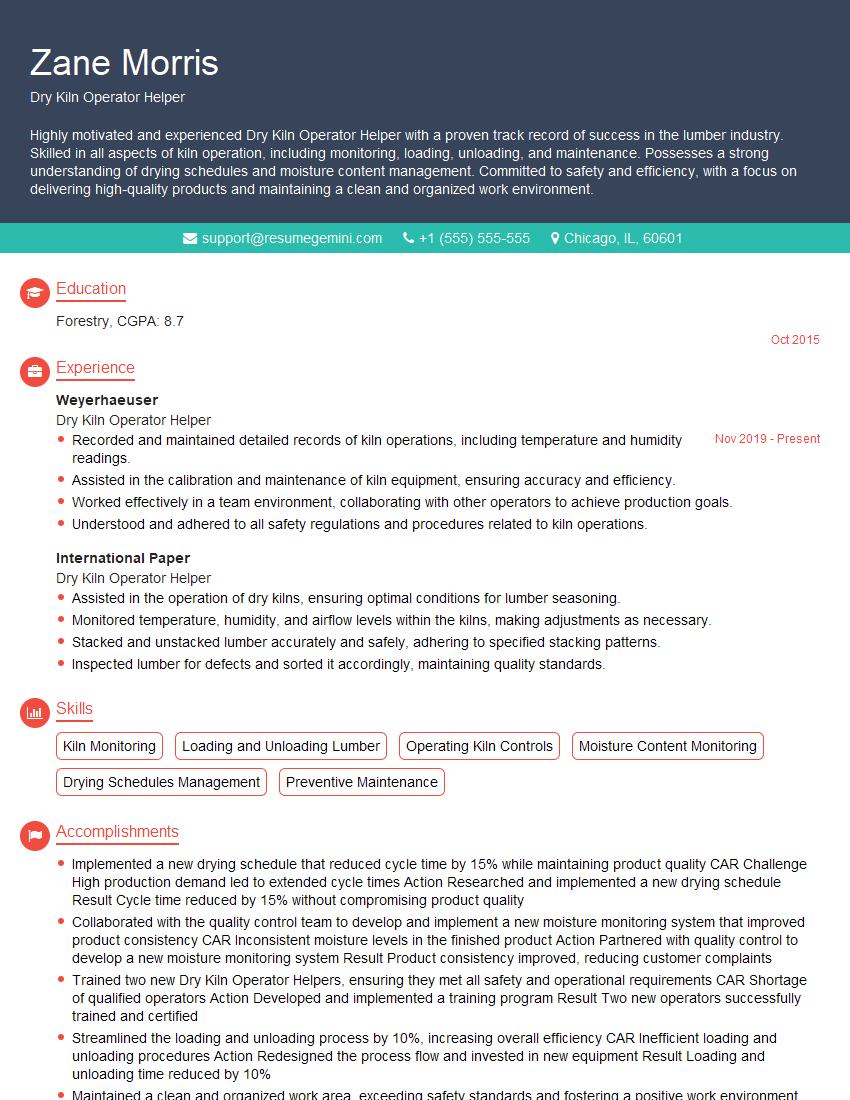

Zane Morris

Dry Kiln Operator Helper

Summary

Highly motivated and experienced Dry Kiln Operator Helper with a proven track record of success in the lumber industry. Skilled in all aspects of kiln operation, including monitoring, loading, unloading, and maintenance. Possesses a strong understanding of drying schedules and moisture content management. Committed to safety and efficiency, with a focus on delivering high-quality products and maintaining a clean and organized work environment.

Education

Forestry

October 2015

Skills

- Kiln Monitoring

- Loading and Unloading Lumber

- Operating Kiln Controls

- Moisture Content Monitoring

- Drying Schedules Management

- Preventive Maintenance

Work Experience

Dry Kiln Operator Helper

- Recorded and maintained detailed records of kiln operations, including temperature and humidity readings.

- Assisted in the calibration and maintenance of kiln equipment, ensuring accuracy and efficiency.

- Worked effectively in a team environment, collaborating with other operators to achieve production goals.

- Understood and adhered to all safety regulations and procedures related to kiln operations.

Dry Kiln Operator Helper

- Assisted in the operation of dry kilns, ensuring optimal conditions for lumber seasoning.

- Monitored temperature, humidity, and airflow levels within the kilns, making adjustments as necessary.

- Stacked and unstacked lumber accurately and safely, adhering to specified stacking patterns.

- Inspected lumber for defects and sorted it accordingly, maintaining quality standards.

Accomplishments

- Implemented a new drying schedule that reduced cycle time by 15% while maintaining product quality CAR Challenge High production demand led to extended cycle times Action Researched and implemented a new drying schedule Result Cycle time reduced by 15% without compromising product quality

- Collaborated with the quality control team to develop and implement a new moisture monitoring system that improved product consistency CAR Inconsistent moisture levels in the finished product Action Partnered with quality control to develop a new moisture monitoring system Result Product consistency improved, reducing customer complaints

- Trained two new Dry Kiln Operator Helpers, ensuring they met all safety and operational requirements CAR Shortage of qualified operators Action Developed and implemented a training program Result Two new operators successfully trained and certified

- Streamlined the loading and unloading process by 10%, increasing overall efficiency CAR Inefficient loading and unloading procedures Action Redesigned the process flow and invested in new equipment Result Loading and unloading time reduced by 10%

- Maintained a clean and organized work area, exceeding safety standards and fostering a positive work environment CAR Unorganized and potentially hazardous work area Action Implemented a daily cleaning and maintenance routine Result Improved safety and productivity

Awards

- Received Employee of the Month award for consistently exceeding production targets and maintaining a safe work environment

- Recognized for outstanding safety record, contributing to a workplace with zero accidents for over a year

- Awarded for exceptional attention to detail and ability to identify and resolve drying issues promptly

- Recognized for innovative thinking and proactive approach to problemsolving in the dry kiln operation

Certificates

- OSHA Safety Certification

- National Hardwood Lumber Association (NHLA) Certification

- American Dry Kiln Institute (ADKI) Certification

- Wood Moisture Meter Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dry Kiln Operator Helper

- Highlight your experience and skills in kiln operation, including any certifications or training you have received.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the job.

- Showcase your commitment to safety by describing your knowledge of safety protocols and your experience in maintaining a safe work environment.

- Proofread your resume carefully for any errors before submitting it.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Dry Kiln Operator Helper Resume

- Monitor kiln conditions and make adjustments as needed to ensure optimal drying conditions.

- Load and unload lumber into and out of the kiln using forklifts and other equipment.

- Operate kiln controls to maintain temperature, humidity, and airflow within specified parameters.

- Monitor moisture content of lumber using moisture meters and make adjustments to drying schedules as needed.

- Manage drying schedules and ensure that lumber is dried to meet customer specifications.

- Perform preventive maintenance on kiln equipment and report any issues to supervisors.

- Maintain a clean and organized work area, adhering to all safety regulations.

Frequently Asked Questions (FAQ’s) For Dry Kiln Operator Helper

What is the role of a Dry Kiln Operator Helper?

A Dry Kiln Operator Helper assists in the operation and maintenance of dry kilns, which are used to dry lumber and other wood products. They load and unload lumber into and out of the kiln, monitor kiln conditions, and make adjustments to ensure optimal drying conditions. They also perform preventive maintenance on kiln equipment and report any issues to supervisors.

What are the qualifications for a Dry Kiln Operator Helper?

Qualifications for a Dry Kiln Operator Helper typically include a high school diploma or equivalent, and some experience in the lumber industry or a related field. Some employers may also require certification or training in kiln operation.

What are the responsibilities of a Dry Kiln Operator Helper?

The responsibilities of a Dry Kiln Operator Helper include loading and unloading lumber into and out of the kiln, monitoring kiln conditions, making adjustments to ensure optimal drying conditions, performing preventive maintenance on kiln equipment, and reporting any issues to supervisors.

What are the skills required for a Dry Kiln Operator Helper?

Skills required for a Dry Kiln Operator Helper include the ability to operate a forklift, knowledge of kiln operation and maintenance, and the ability to work in a physically demanding environment.

What is the salary range for a Dry Kiln Operator Helper?

The salary range for a Dry Kiln Operator Helper can vary depending on experience, location, and employer. According to Salary.com, the average salary for a Dry Kiln Operator Helper in the United States is $40,000 per year.

What is the job outlook for a Dry Kiln Operator Helper?

The job outlook for a Dry Kiln Operator Helper is expected to be good over the next few years. As the construction industry continues to grow, so will the demand for dried lumber and other wood products. This will lead to increased demand for Dry Kiln Operator Helpers.