Are you a seasoned Dry Molder seeking a new career path? Discover our professionally built Dry Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

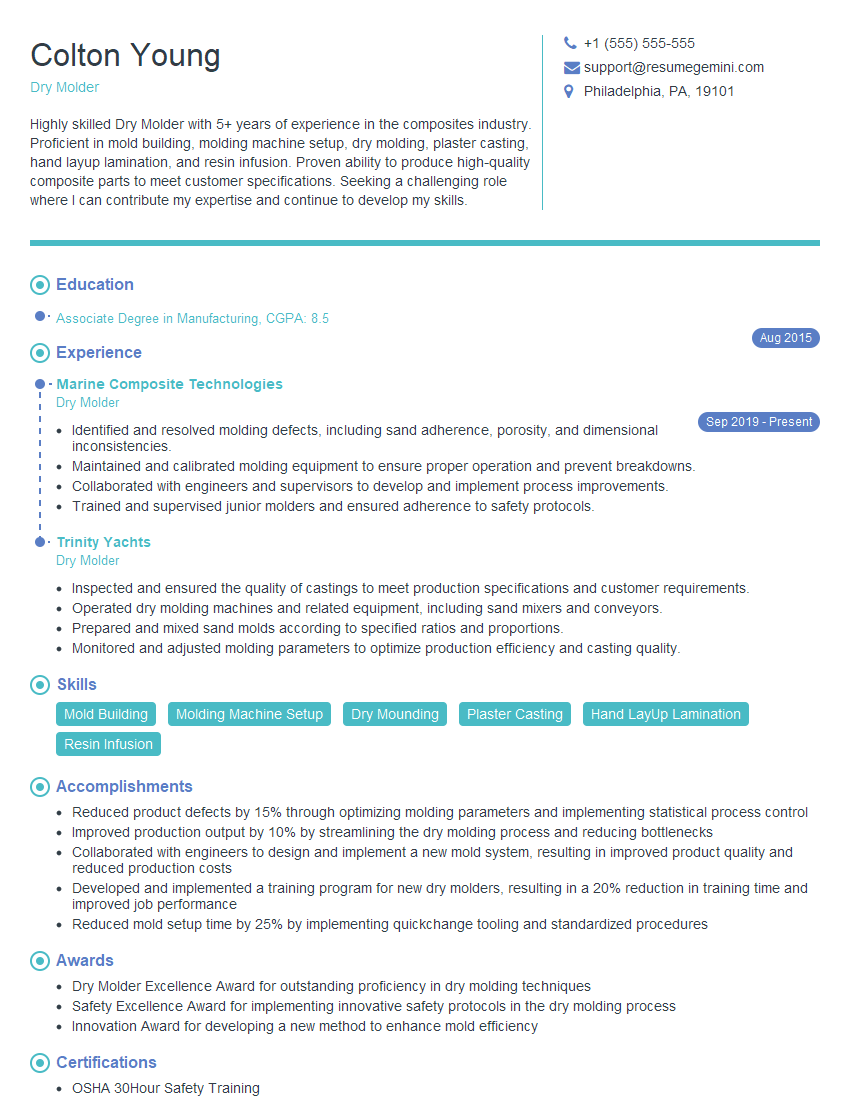

Colton Young

Dry Molder

Summary

Highly skilled Dry Molder with 5+ years of experience in the composites industry. Proficient in mold building, molding machine setup, dry molding, plaster casting, hand layup lamination, and resin infusion. Proven ability to produce high-quality composite parts to meet customer specifications. Seeking a challenging role where I can contribute my expertise and continue to develop my skills.

Education

Associate Degree in Manufacturing

August 2015

Skills

- Mold Building

- Molding Machine Setup

- Dry Mounding

- Plaster Casting

- Hand LayUp Lamination

- Resin Infusion

Work Experience

Dry Molder

- Identified and resolved molding defects, including sand adherence, porosity, and dimensional inconsistencies.

- Maintained and calibrated molding equipment to ensure proper operation and prevent breakdowns.

- Collaborated with engineers and supervisors to develop and implement process improvements.

- Trained and supervised junior molders and ensured adherence to safety protocols.

Dry Molder

- Inspected and ensured the quality of castings to meet production specifications and customer requirements.

- Operated dry molding machines and related equipment, including sand mixers and conveyors.

- Prepared and mixed sand molds according to specified ratios and proportions.

- Monitored and adjusted molding parameters to optimize production efficiency and casting quality.

Accomplishments

- Reduced product defects by 15% through optimizing molding parameters and implementing statistical process control

- Improved production output by 10% by streamlining the dry molding process and reducing bottlenecks

- Collaborated with engineers to design and implement a new mold system, resulting in improved product quality and reduced production costs

- Developed and implemented a training program for new dry molders, resulting in a 20% reduction in training time and improved job performance

- Reduced mold setup time by 25% by implementing quickchange tooling and standardized procedures

Awards

- Dry Molder Excellence Award for outstanding proficiency in dry molding techniques

- Safety Excellence Award for implementing innovative safety protocols in the dry molding process

- Innovation Award for developing a new method to enhance mold efficiency

Certificates

- OSHA 30Hour Safety Training

- CPR and First Aid Certification

- Composite Molding Certification

- Advanced Composite Materials Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dry Molder

- – Highlight your experience and skills in mold building and molding machine setup, as these are essential for a Dry Molder.

- – Showcase your knowledge of composite materials and processes, including dry molding, plaster casting, hand layup lamination, and resin infusion.

- – Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the company’s success.

- – Proofread your resume carefully for any errors in grammar or spelling, as attention to detail is crucial in this role.

Essential Experience Highlights for a Strong Dry Molder Resume

- – Construct and maintain molds for composite parts using a variety of materials and techniques, including wet layup, vacuum infusion, and autoclave curing.

- – Setup and operate molding machines to produce composite parts according to specifications.

- – Perform dry molding operations, such as mixing and applying dry materials to molds.

- – Create plaster casts for use in mold making and prototyping.

- – Laminate composite parts using hand layup techniques, ensuring proper resin-to-fiber ratio and fiber orientation.

- – Infuse composite parts with resin using vacuum infusion techniques to achieve optimal fiber wet-out and strength.

- – Inspect finished composite parts to ensure quality and adherence to specifications.

Frequently Asked Questions (FAQ’s) For Dry Molder

What is the role of a Dry Molder?

A Dry Molder is responsible for constructing and maintaining molds, setting up and operating molding machines, and performing dry molding operations to produce composite parts. They also create plaster casts for use in mold making and prototyping, and laminate composite parts using hand layup techniques. In addition, they infuse composite parts with resin using vacuum infusion techniques to achieve optimal fiber wet-out and strength.

What are the key skills required for a Dry Molder?

Key skills for a Dry Molder include mold building, molding machine setup, dry molding, plaster casting, hand layup lamination, resin infusion, and quality control. They should also have a strong understanding of composite materials and processes, as well as the ability to read and interpret technical drawings.

What is the work environment of a Dry Molder like?

Dry Molders typically work in a manufacturing environment, where they may be exposed to dust, fumes, and noise. They may also work with heavy machinery and hazardous chemicals, so it is important to follow proper safety procedures.

What are the career prospects for a Dry Molder?

Dry Molders with experience and expertise can advance to supervisory or management positions. They may also specialize in a particular area of composite manufacturing, such as mold design or process development.

How can I become a Dry Molder?

To become a Dry Molder, you typically need an associate degree in manufacturing or a related field. Additionally, hands-on experience in composite manufacturing is highly beneficial. You can gain experience through internships, apprenticeships, or entry-level positions in the industry.

What is the average salary for a Dry Molder?

The average salary for a Dry Molder in the United States is around $50,000 per year. However, salaries can vary depending on experience, location, and company size.